Preparation method of printing-grade conductive adhesive

A conductive adhesive, printing-grade technology, applied in the direction of conductive adhesives, monocarboxylate copolymer adhesives, adhesive types, etc., can solve the problem of high preparation cost, X, Y direction resistance and Z direction resistance value High, waste of auxiliary materials and other issues, to achieve good market application value, high overall viscosity, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method for printing-grade conductive adhesive, comprising the steps:

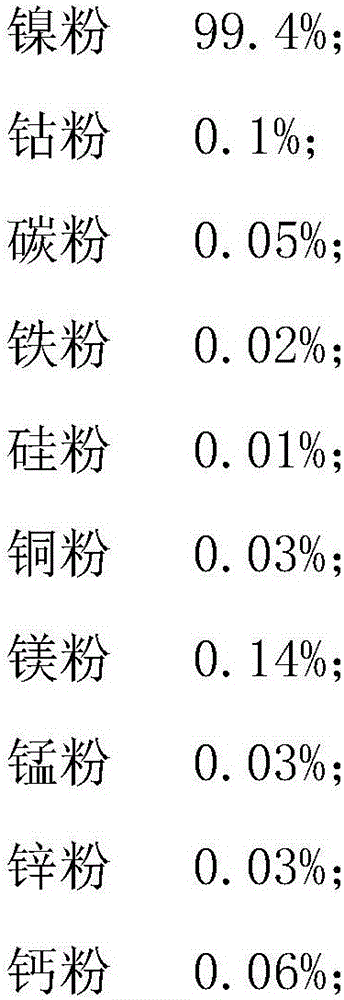

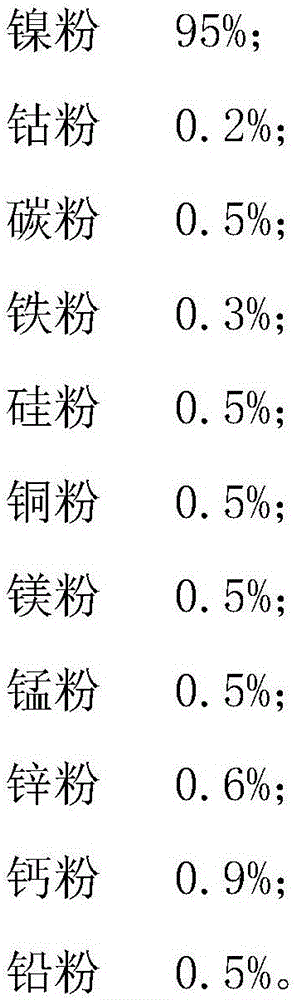

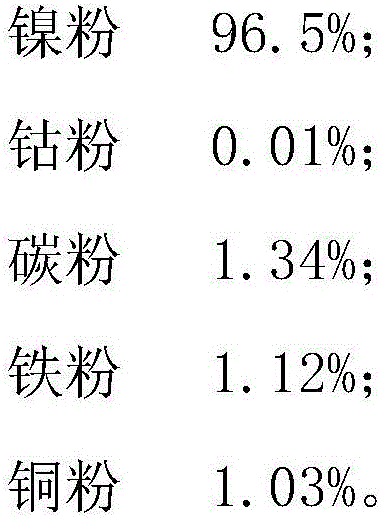

[0021] S1: Add 70%-93% water glue, 4%-20% conductive powder, 2%-10% pure water to the reactor, wherein the conductive powder includes the first metal conductive powder and the second Two metal conductive powders, the first metal conductive powder is nickel powder;

[0022] S2: Use a mixer to stir, and the stirring time is greater than or equal to one hour;

[0023] S3: Heating the solution inside the reaction kettle (the heating temperature is preferably greater than or equal to 80 degrees Celsius, and the time is greater than 1 hour) and drying to prepare a printing-grade conductive adhesive.

[0024] Preferably, the second conductive powder is one or more of cobalt powder, carbon powder, iron powder, silicon powder, copper powder, magnesium powder, manganese powder, zinc powder, calcium powder, and lead powder.

[0025] Preferably, the water glue is 3M7533 water glue.

[0026] Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com