Piston for avoiding clamping stagnation

A piston and integrated technology, which is applied in the direction of piston, cylindrical piston, plunger, etc., can solve the problems of pilot control valve piston sticking, etc., and achieve the effects of reducing maintenance costs, long service life, improving use efficiency and use quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

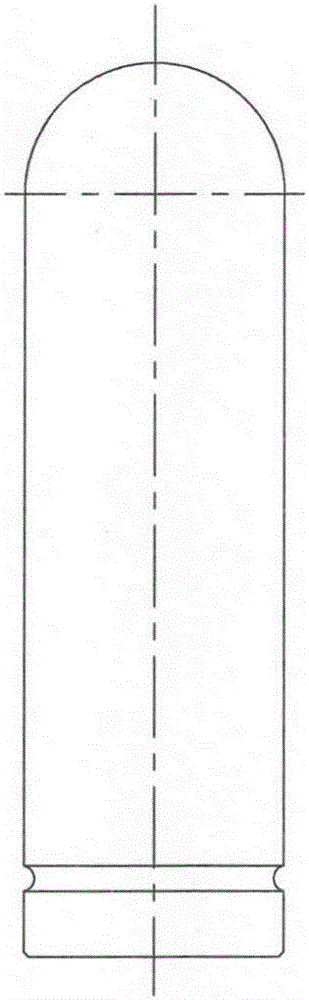

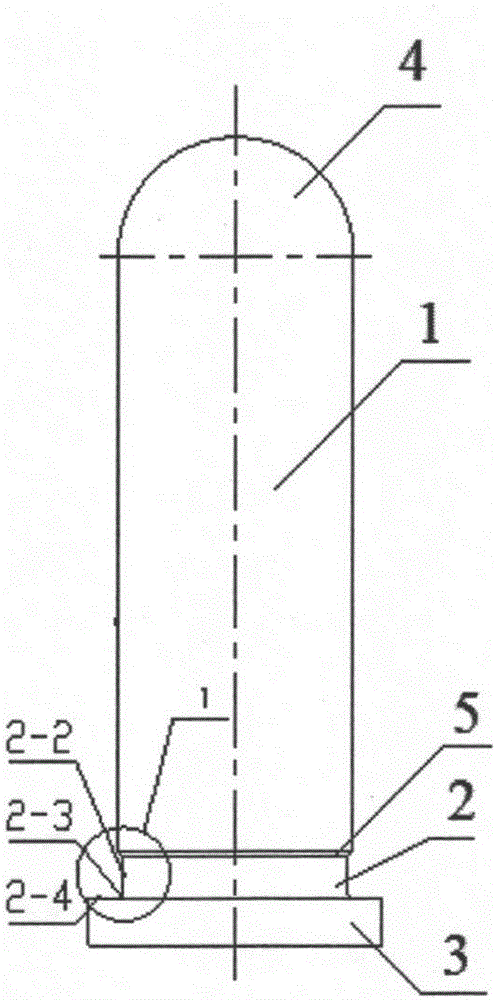

[0017] Such as figure 2 As shown, the piston of the present invention that avoids sticking is composed of a hemispherical part 4, a first part 1, a rounded frustum-shaped part 5, a second part 2 and a third part 3 from top to bottom, the first part 1, the second part The second part 2 and the third part 3 are cylindrical, and the upper side of the first part 1 is provided with a hemispherical part 4, and the transition between the first part 1 and the second part 2 is through a rounded frustum-shaped part 5, and the inverted The outer diameter of the top surface of the frustum-shaped part 5 is equal to the outer diameter of the first part 1, and the outer diameter of the bottom surface of the rounded truncated part 5 is equal to the outer diameter of the second part 2. The hemispherical part 4, the first part 1 , The rounded frustum-shaped part 5, the second part 2 and the third part 3 are integrally formed.

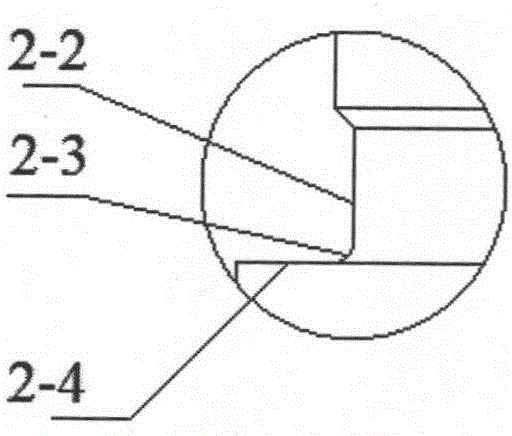

[0018] Such as image 3 As shown, the outer diameter of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com