Spherical composite gas cylinder for spaceflight

A technology of composite materials and composite material layers, which is applied in the field of thin-walled metal lining/fiber winding composite gas cylinders, can solve the problems of increasing structural quality, immaturity of spherical composite gas cylinders, and reducing safety, and achieve structural quality The effect of small size, abundant types, optimized structure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] like Figure 1-2 shown, including the following steps:

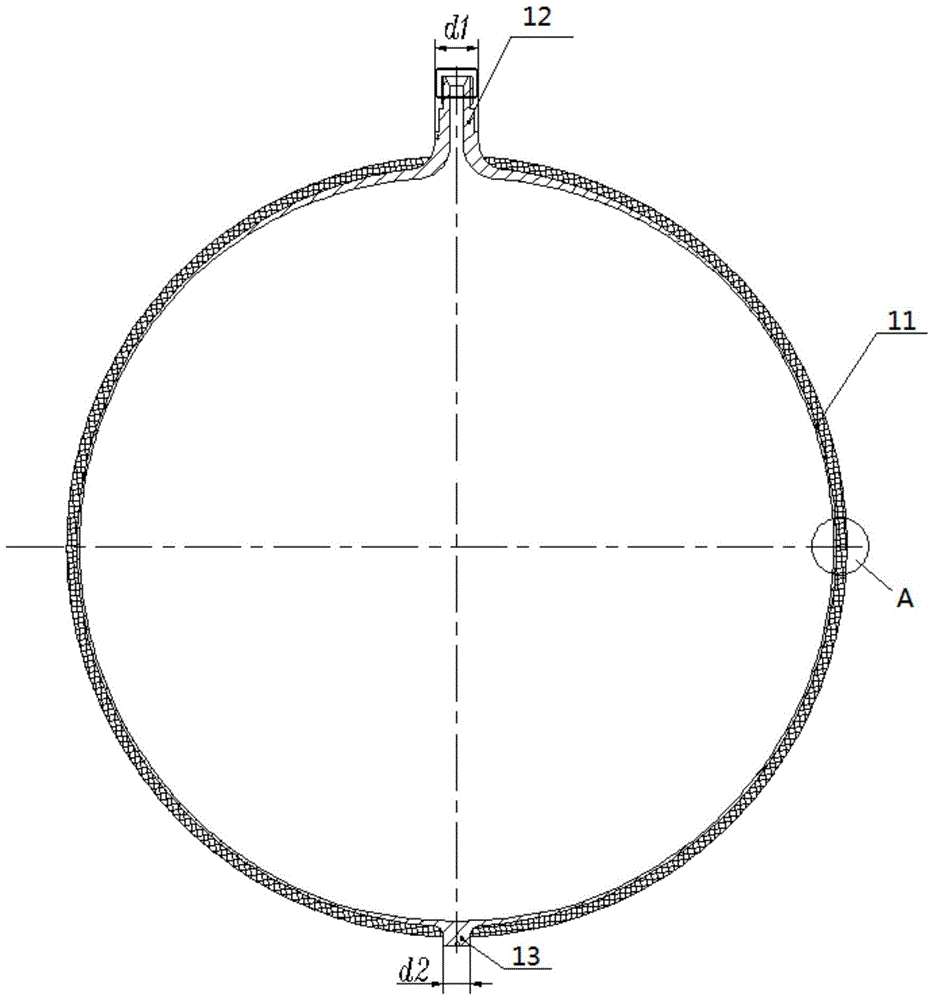

[0023] Step 1: The metal lining 1 is composed of a spherical shell 11 , a nozzle 12 and a boss 13 , and the nozzle and the boss 13 are respectively located at the two ends of the axis of the spherical shell 11 .

[0024] Step 2: The material for preparing the metal lining 1 is aluminum alloy 6061, and the spherical shell 11, the nozzle 12 and the boss 13 constituting the metal lining 1 are integrally formed by stamping, spinning and machining processes, and seamlessly connected.

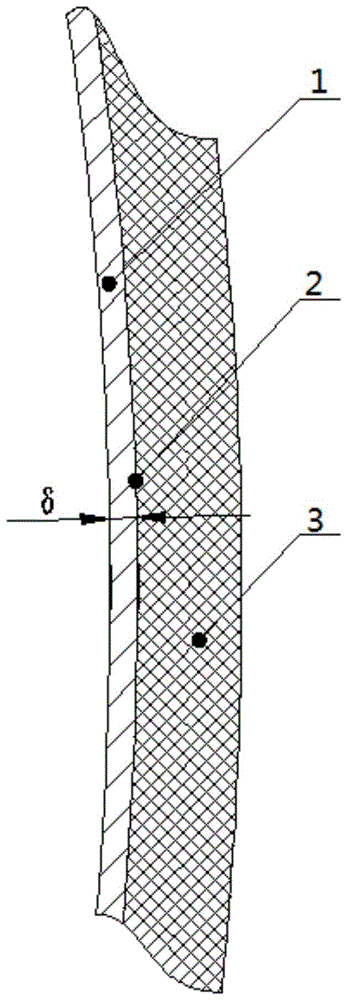

[0025] Step 3: The wall thickness of the thin film area of the spherical shell 11 is equal, and the thickness gradually increases in the transition area between the spherical shell 11 and the connecting nozzle 12 and the boss 13 .

[0026] Step 4: The adhesive layer 2 is evenly laid on the outer surface of the spherical shell 11 according to the predetermined thickness, the purpose is to firmly connect the spherical shell 11 of the me...

Embodiment 2

[0031] like Figure 3-4 shown, including the following steps:

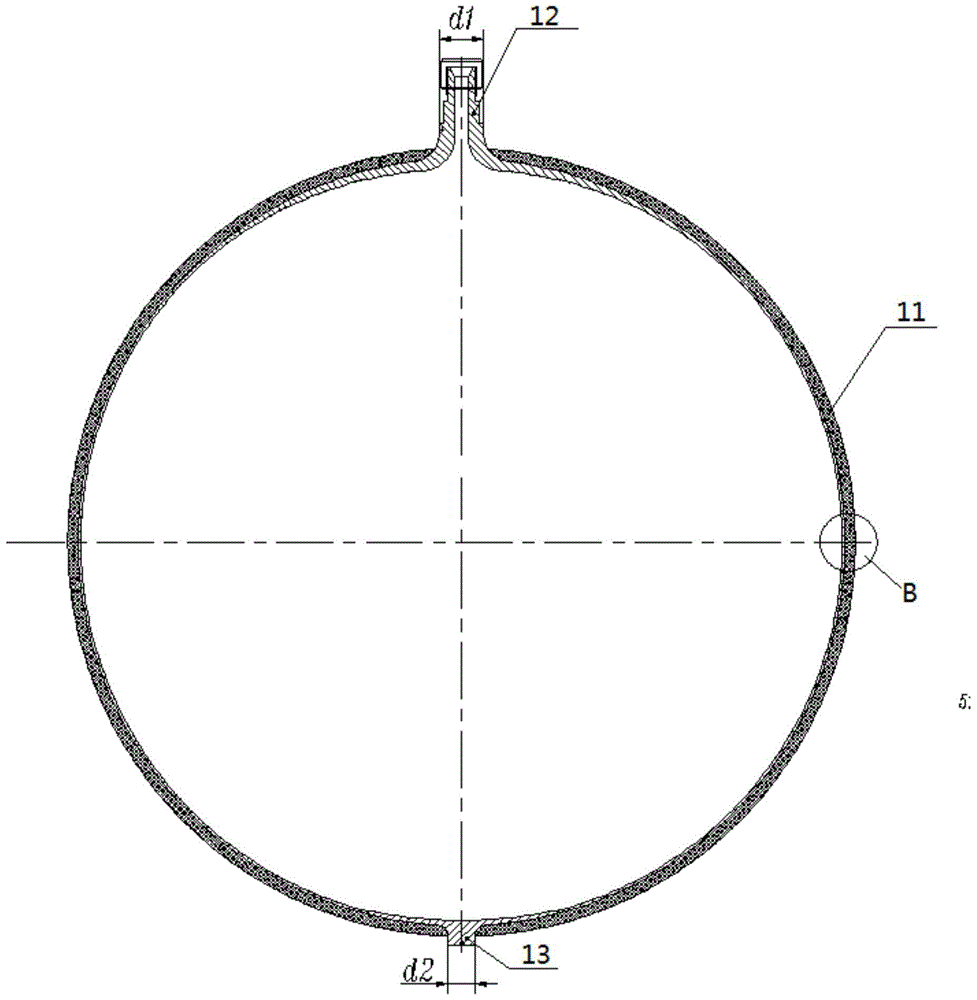

[0032] Step 1: The metal lining 1 is composed of a spherical shell 11 , a nozzle 12 and a boss 13 , and the nozzle and the boss 13 are respectively located at the two ends of the axis of the spherical shell 11 .

[0033] Step 2: The material for preparing the metal lining 1 is one of titanium alloys TA0, TA1, TA2, TA3, TA4, TA5, TA6, TA7, TA8, TA9, TA10 and TC4, which constitute the spherical shell 11 of the metal lining 1 , The nozzle 12 and the boss 13 are formed by forging and machining, and welded and assembled at the equator of the spherical shell 11 of the metal lining 1.

[0034] Step 3: The wall thickness of the thin film area of the spherical shell 11 is equal, and the thickness gradually increases in the transition area between the spherical shell 11 and the connecting nozzle 12 and the boss 13 .

[0035] Step 4: The adhesive layer 2 is evenly laid on the outer surface of the spherical shell 11 accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com