Characteristic coincidence degree comparison method for onsite defect linear trace

A linear trace and coincidence technology, applied in the field of criminal investigation science, can solve the problems of high price and cost, loss, etc., and achieve the effect of improving efficiency and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

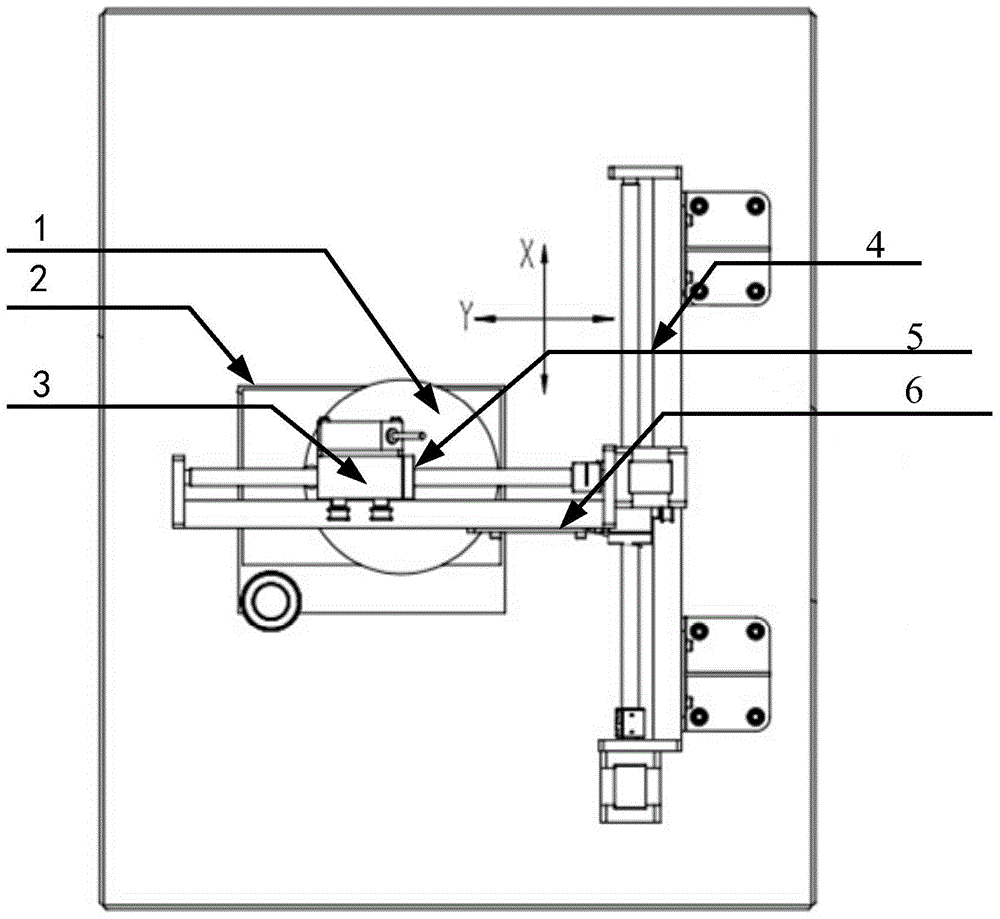

[0036] Embodiment 1: as Figure 1-7 As shown, a method for comparing the coincidence degree of incomplete linear trace features on the spot, the specific steps of the coincidence degree comparison method for the incomplete linear trace features on the spot are as follows:

[0037] Step 1. Use the laser displacement sensor of the linear trace laser detection test bench device to horizontally detect the incomplete linear trace surface on the trace bearing body to form a detection signal waveform f(x);

[0038] Step2. Through wavelet decomposition, the laser detection signal waveform f(x) is subjected to data smoothing processing to eliminate background noise interference and obtain a smoothed signal f 1 (x);

[0039] In the step Step2, the specific steps are:

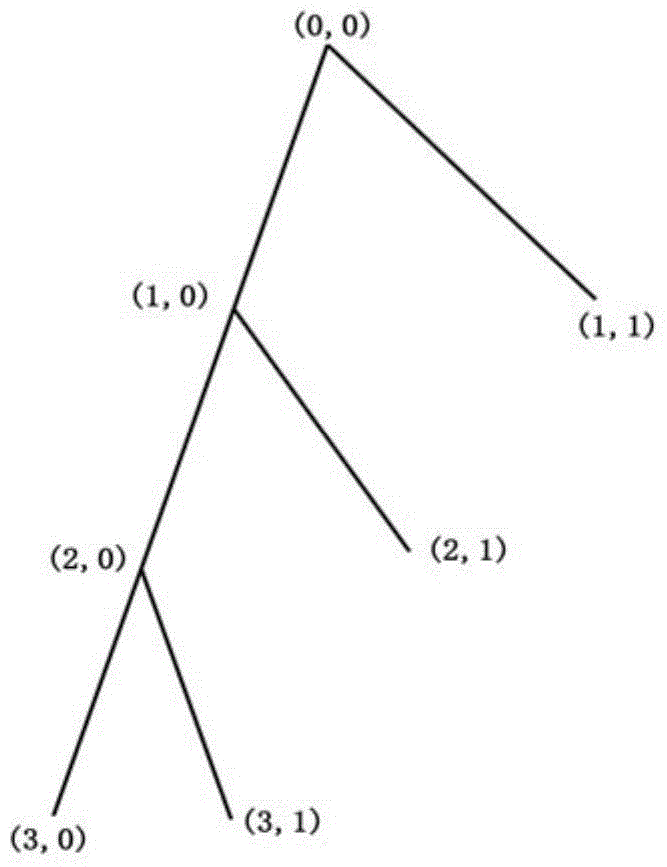

[0040] Step2.1. Decompose the original signal into two parts according to the following formula:

[0041] f = a n + Σ i ...

Embodiment 2

[0051] Embodiment 2: as Figure 1-7 As shown, a method for comparing coincidence degree of on-site incomplete linear trace features, this embodiment is the same as Embodiment 1, the difference is that this embodiment is explained with an actual case:

[0052] The specific steps of the on-site incomplete linear trace feature coincidence degree comparison method are as follows:

[0053] Step 1. Use the laser displacement sensor of the linear trace laser detection test bench device to horizontally detect the incomplete linear trace surface on the trace bearing body to form a detection signal waveform f(x);

[0054] Step2. Through wavelet decomposition, the laser detection signal waveform f(x) is subjected to data smoothing processing to eliminate background noise interference and obtain a smoothed signal f 1 (x);

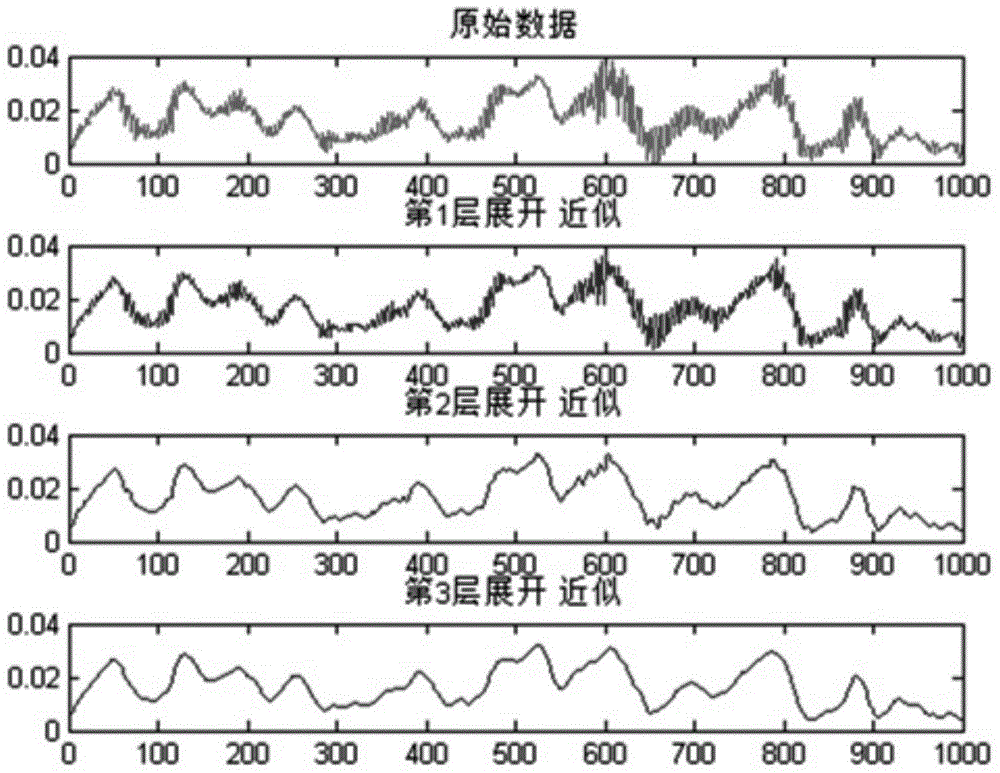

[0055] Such as Figure 2-3 As shown, in the actual noise reduction process, the original signal f(t) needs to be decomposed into multiple layers. The more layers ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com