A kind of supercritical carbon dioxide capillary viscometer under high temperature and high pressure and using method

A technology of capillary viscometer and carbon dioxide, which is applied in the field of rheology measurement, can solve problems such as measurement errors, achieve the effects of improving experimental accuracy, avoiding human operation factors, and avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

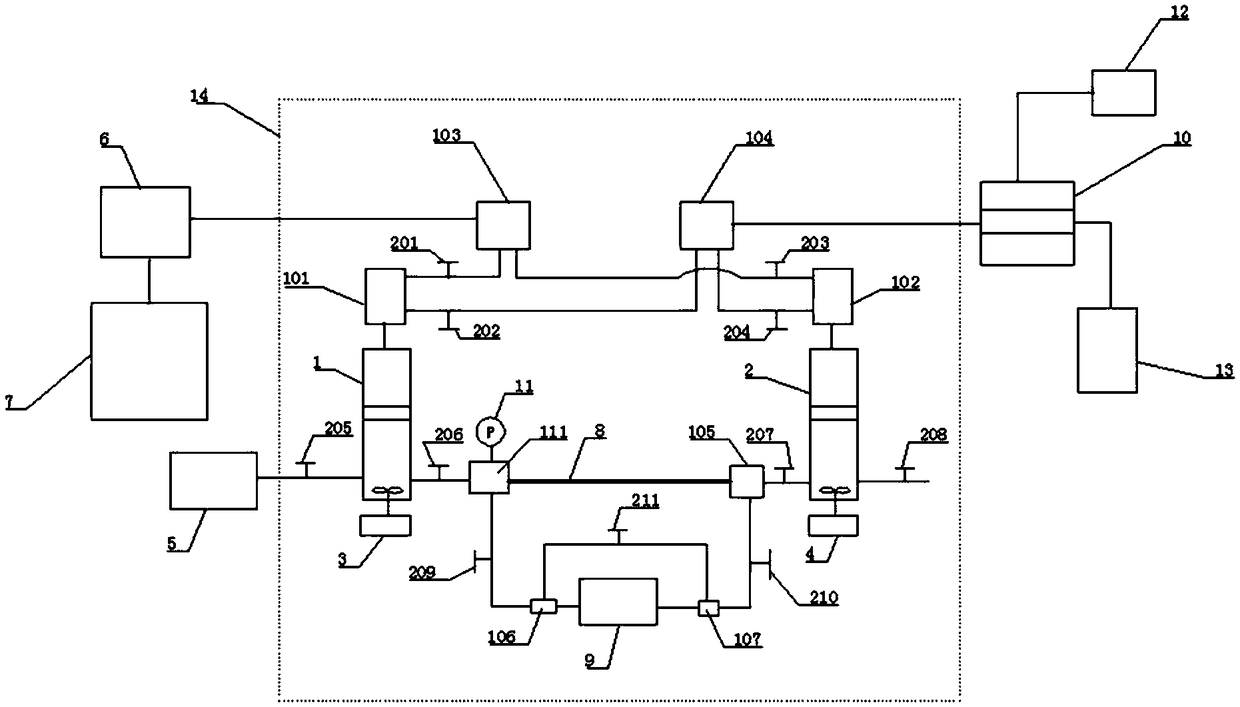

Method used

Image

Examples

Embodiment 1

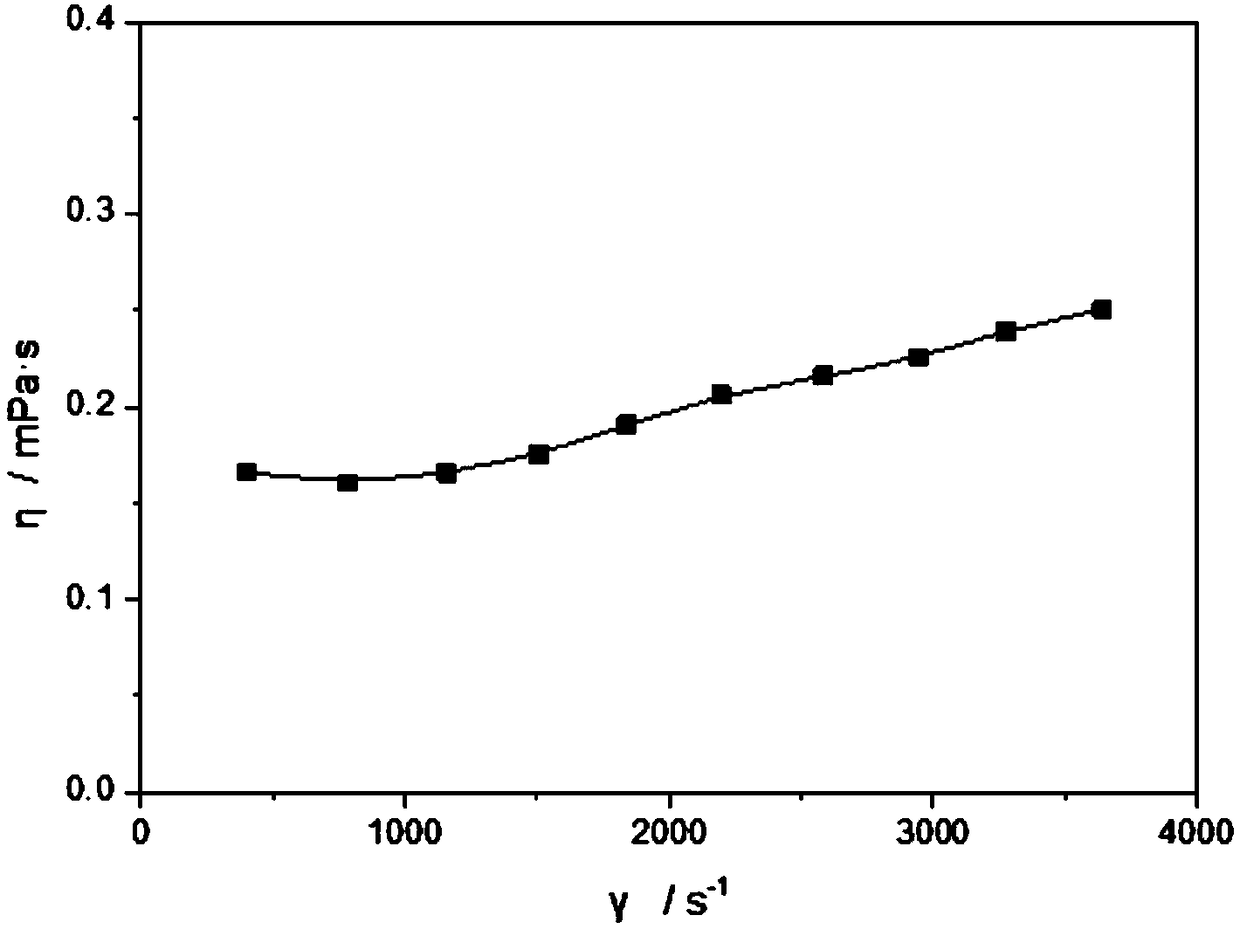

[0073] Select a polished capillary 8 with a radius of 0.3mm and a length of 0.5m, add 10g of ethanol and 190g of carbon dioxide to the lower part of the piston of the first intermediate container 1, set the temperature of the thermostat 14 to 40°C, and set the backpressure of the backpressure valve 10 to 20MPa , adjust the stirring speed of the first magnetic stirring motor 3 and the second magnetic stirring motor 4 to be 300rad / min. Set the flow rate Q of constant speed and constant pressure tracking pump 6 to 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0mL / min, and record the corresponding pressure difference Δp as 0.22, 0.42, 0.64, 0.88, 1.17, 1.51, 1.86, 2.21, 2.61, 3.04Mpa, through the formulas ②, ③, ④, draw the curve of the viscosity of the supercritical carbon dioxide-ethanol system changing with the shear rate when the temperature is 40°C and the pressure is 20MPa, Such as figure 2 shown.

Embodiment 2

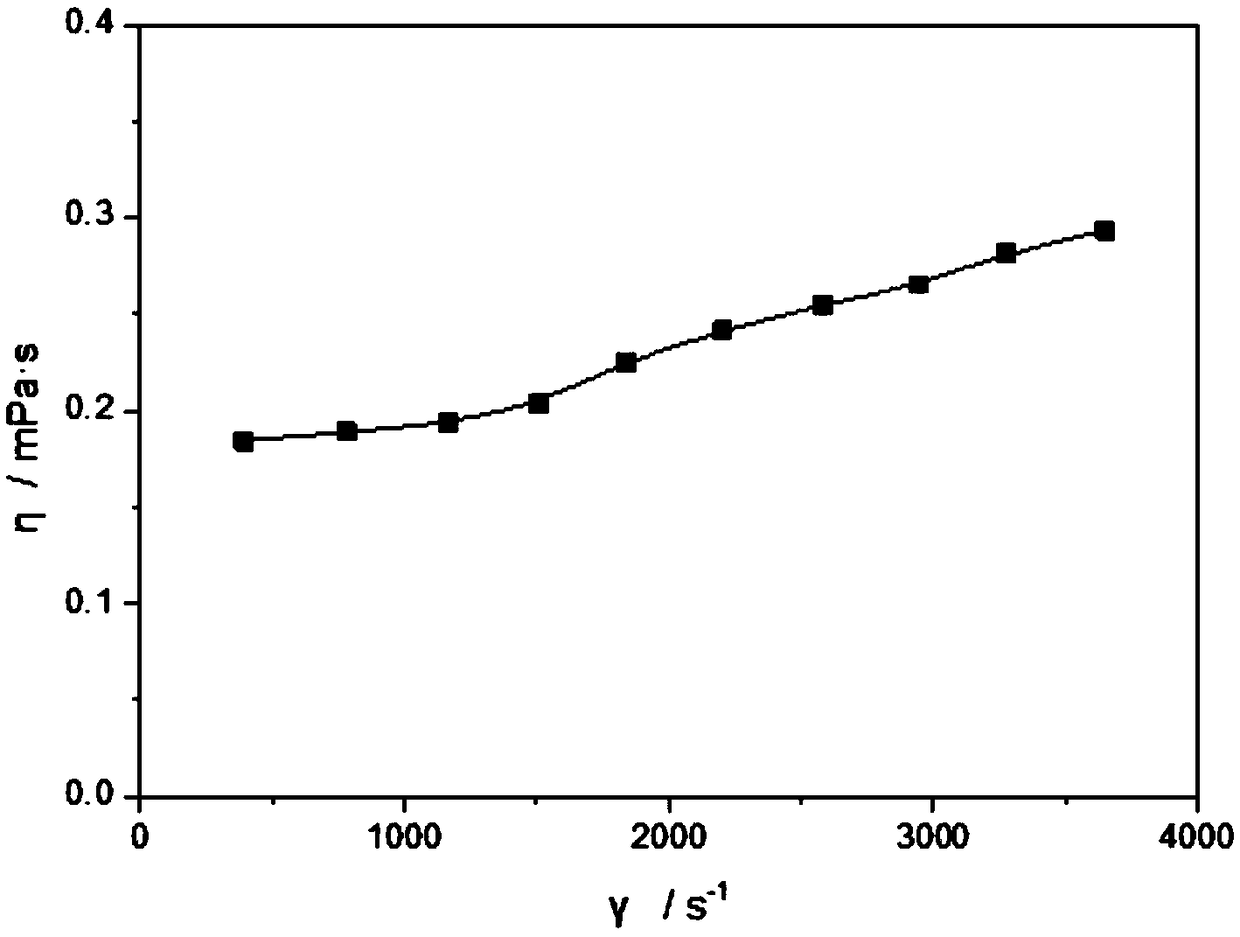

[0075] The back pressure valve 10 is set to a back pressure of 30 MPa, and other conditions are set according to Embodiment 1, and the flow Q of the constant speed and constant pressure tracking pump 6 is respectively 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, When 4.5, 5.0mL / min, the corresponding pressure difference Δp is 0.24, 0.49, 0.75, 1.02, 1.38, 1.77, 2.19, 2.60, 3.07, 3.57Mpa respectively, through the formula ②, ③, ④, the drawn temperature is 40℃ , When the pressure is 30MPa, the viscosity of the supercritical carbon dioxide-ethanol system changes with the shear rate curve, such as image 3 shown.

Embodiment 3

[0077] The temperature of the constant temperature device 14 is adjusted to 50°C, and other conditions are set according to Example 1, and the flow Q of the constant speed and constant pressure tracking pump 6 is respectively 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5 , 5.0mL / min, the corresponding pressure difference Δp is 0.18, 0.34, 0.53, 0.73, 0.96, 1.24, 1.53, 1.82, 2.14, 2.50Mpa, respectively, through the formula ②, ③, ④, draw the temperature as 50 ℃, When the pressure is 20MPa, the viscosity of the supercritical carbon dioxide-ethanol system changes with the shear rate curve, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| processing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com