A kind of pedot conductive ink capable of ultraviolet light dimerization and preparation method thereof

A conductive ink and ultraviolet light technology, applied in inks, household appliances, applications, etc., can solve the problems of complex preparation process, poor water resistance and weather resistance, and achieve the effect of improving conductivity, water resistance and weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

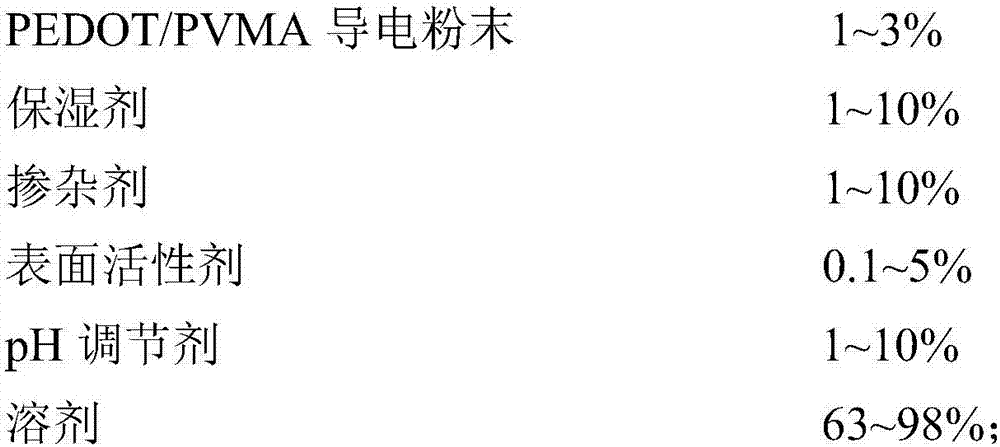

Method used

Image

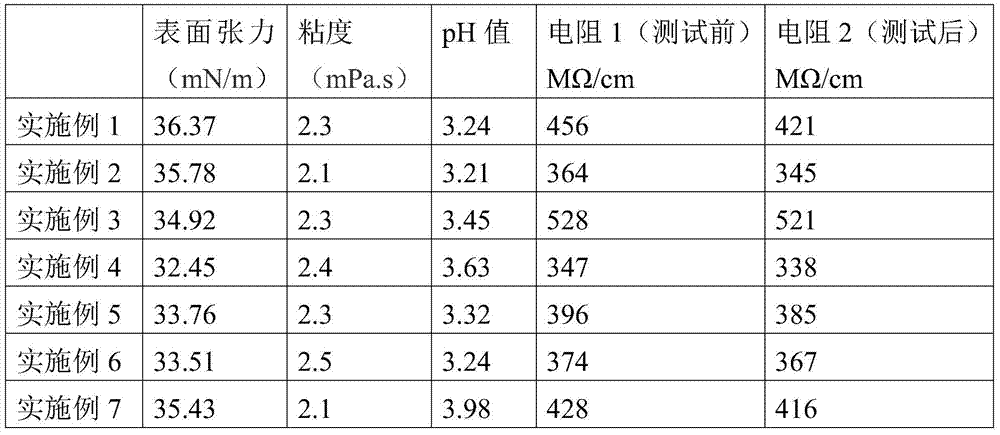

Examples

Embodiment 1

[0025] A kind of PEDOT conductive ink that can ultraviolet dimerization, the preparation method of this conductive ink comprises the steps:

[0026] (1) Dissolve 1g of PEDOT / PVMA conductive powder in a mixed solvent composed of 23g of deionized water and 17g of ethanol, then add 3g of dopant DMSO, 3.5g of humectant glycerin, and 1.5g of surfactant Triton X -100 and 2.5g of 5wt% hydrochloric acid solution, through magnetic stirring (under the condition of 400rpm, stirring for 10h), ultrasonic (ultrasonic power is 400W, time is 30 minutes) to obtain a uniformly dispersed mixed solution;

[0027] (2) Filtrating the mixed solution obtained in step (1) through a microporous filter membrane with a pore size of 0.22 μm to obtain the conductive ink for inkjet printing.

[0028] The PEDOT / PVMA conductive powder is a mixture of (7-(4-vinylbenzyloxy)-4-methylcoumarin)-alt-maleic anhydride and poly 3,4-ethylenedioxythiophene, the The preparation method of PEDOT / PVMA conductive powder is:...

Embodiment 2

[0031] A kind of PEDOT conductive ink that can ultraviolet dimerization, the preparation method of this conductive ink comprises the steps:

[0032] (1) Dissolve 1g of PEDOT / PVMA conductive powder in a mixed solvent composed of 16g of deionized water and 11g of isopropanol, then add 2.67g of dopant DMSO, 1.67g of humectant ethylene glycol, and 0.33g of surfactant koji Pull through X-100 and 0.67g of 5wt% hydrochloric acid solution, magnetic stirring (under the condition of 200rpm, stirring for 24h), ultrasonic (ultrasonic power of 600W, time of 20 minutes) to obtain a uniformly dispersed mixed solution;

[0033] (2) Filtrating the mixed solution obtained in step (1) through a microporous filter membrane with a pore size of 0.30 μm to obtain the conductive ink for inkjet printing.

[0034] The PEDOT / PVMA conductive powder is a mixture of (7-(4-vinylbenzyloxy)-4-methylcoumarin)-alt-maleic anhydride and poly 3,4-ethylenedioxythiophene, the The preparation method of PEDOT / PVMA ...

Embodiment 3

[0037] A kind of PEDOT conductive ink that can ultraviolet dimerization, the preparation method of this conductive ink comprises the steps:

[0038](1) Dissolve 1g PEDOT / PVMA conductive powder in a mixed solvent composed of 13g deionized water, 8g ethanol and 4.7g diethyl butyl ether, then add .03g dopant DMSO, 3.3g humectant glycerol, 0.33 g surfactant Triton X-100 and 1.33g 5wt% hydrochloric acid solution, through magnetic stirring (under the condition of 500rpm, stirring 1h), ultrasonic (ultrasonic power is 200W, the time is 40 minutes) to obtain uniformly dispersed mixed solution;

[0039] (2) Filtrating the mixed liquid obtained in step (1) through a microporous filter membrane with a pore size of 0.45 μm to obtain the conductive ink for inkjet printing.

[0040] The PEDOT / PVMA conductive powder is a mixture of (7-(4-vinylbenzyloxy)-4-methylcoumarin)-alt-maleic anhydride and poly 3,4-ethylenedioxythiophene, the The preparation method of PEDOT / PVMA conductive powder is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com