Method and system for correcting scanning range of piezoelectric ceramic tube scanner

A piezoelectric ceramic tube and scanning range technology, applied in the field of microscopy, can solve the problems of large thickness difference, large scanning range error, inaccuracy and reliability, etc., and achieve the effect of low cost and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

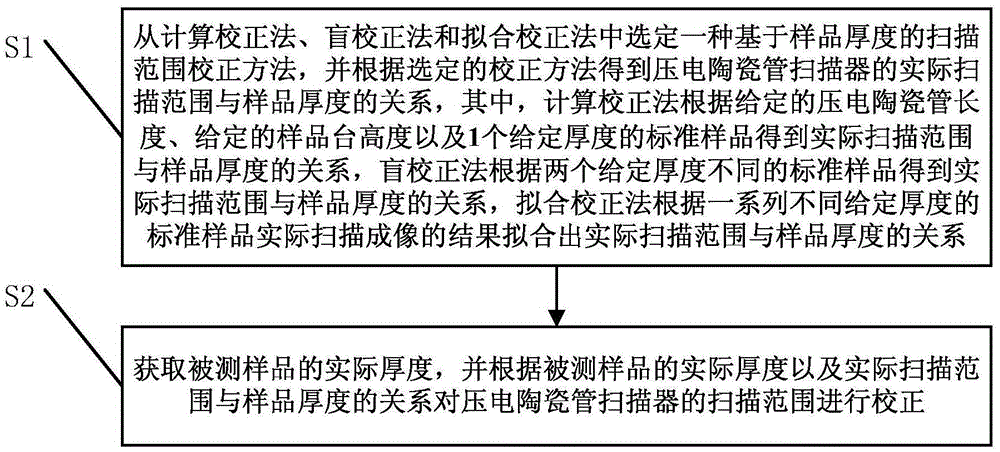

Method used

Image

Examples

Embodiment 1

[0089] This embodiment describes the basic principles of the present invention and related theories involved.

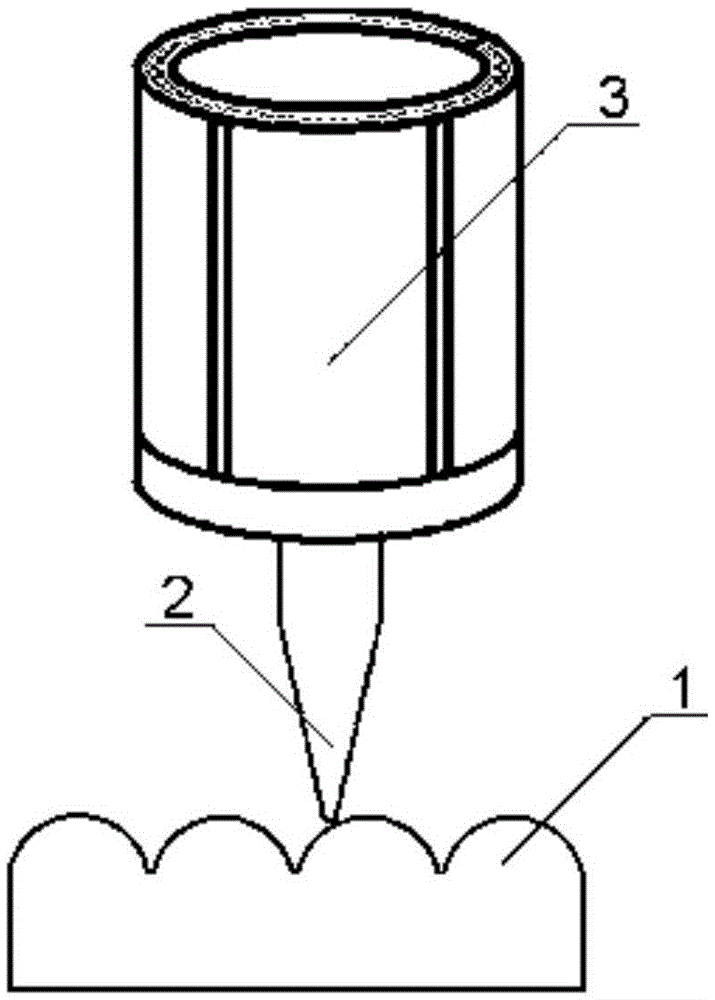

[0090] The scanning probe microscope controls the probe to scan the surface of the sample through the piezoelectric scanner, and simultaneously detects and records the interaction signal between the probe and the sample, so as to obtain the surface information of the sample. Probe-to-sample scanning is actually a controllable relative movement between the probe and the sample, which can be done by either probe scanning or sample scanning, such as image 3 and 4 shown.

[0091] image 3 and 4 Among them, 1 is the sample to be tested, 2 is the probe, 3 is the piezoelectric scanner, image 3 is the probe scanning method, Figure 4 It is the sample scanning mode. In fact, the scanning motion of the probe and the sample is the relative motion of the two. These two methods are equivalent, but the current scanning probe microscope generally integrates a variety of det...

Embodiment 2

[0129] In order to improve the automation of the scanning probe microscope and make it more convenient for users to use, for the scanning probe microscope, the present invention proposes a technology for automatically measuring the thickness of the sample. This technology is combined with the scanning range correction method of the first embodiment. When the sample is tested, the thickness of the sample can be obtained automatically, and the automatic online correction of the scanning range can be realized.

[0130] The structure of the scanning probe microscope probe used for automatic measurement such as Figure 11 shown. Figure 11 Among them, 12 is a measuring head, 5 is a base, 2 is a probe, 3 is a scanner, 1 is a sample, 13 is a precision screw, and 14 is a stepping motor. The scanning probe microscope scans the surface of the sample by the probe in the probe controlled by the system to obtain the surface information of the sample. The probe is mainly composed of a meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com