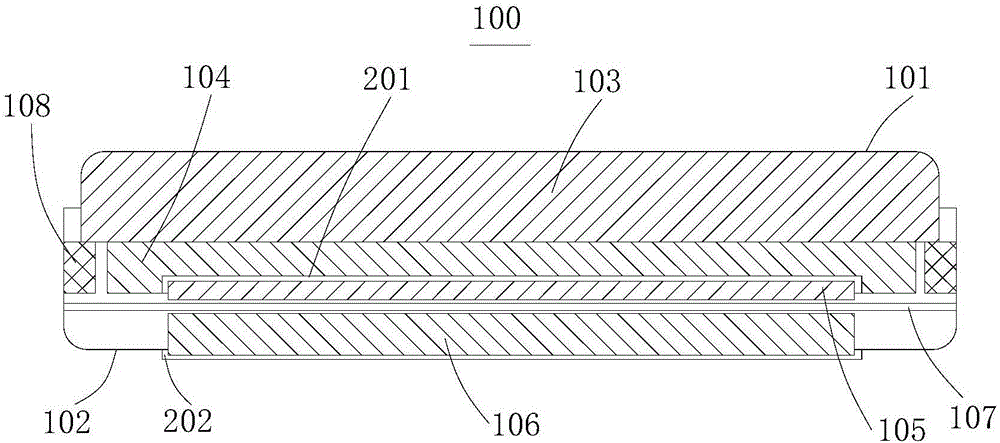

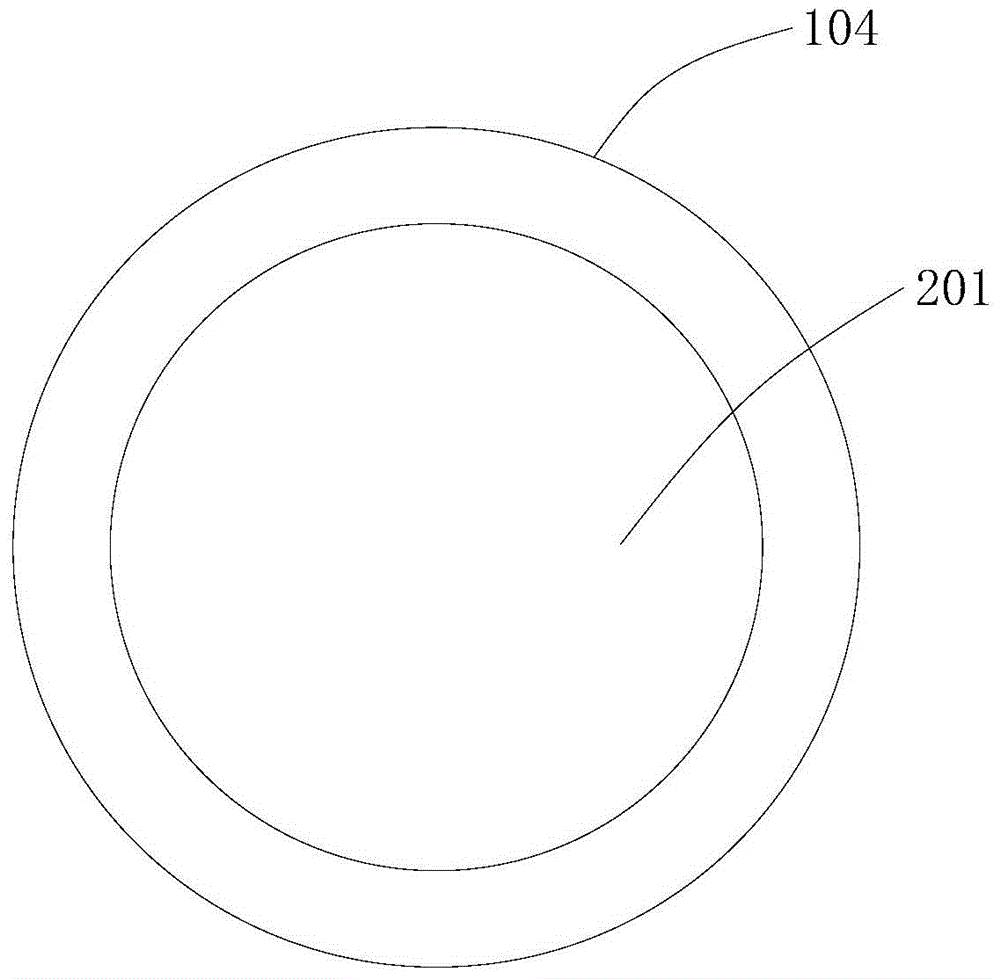

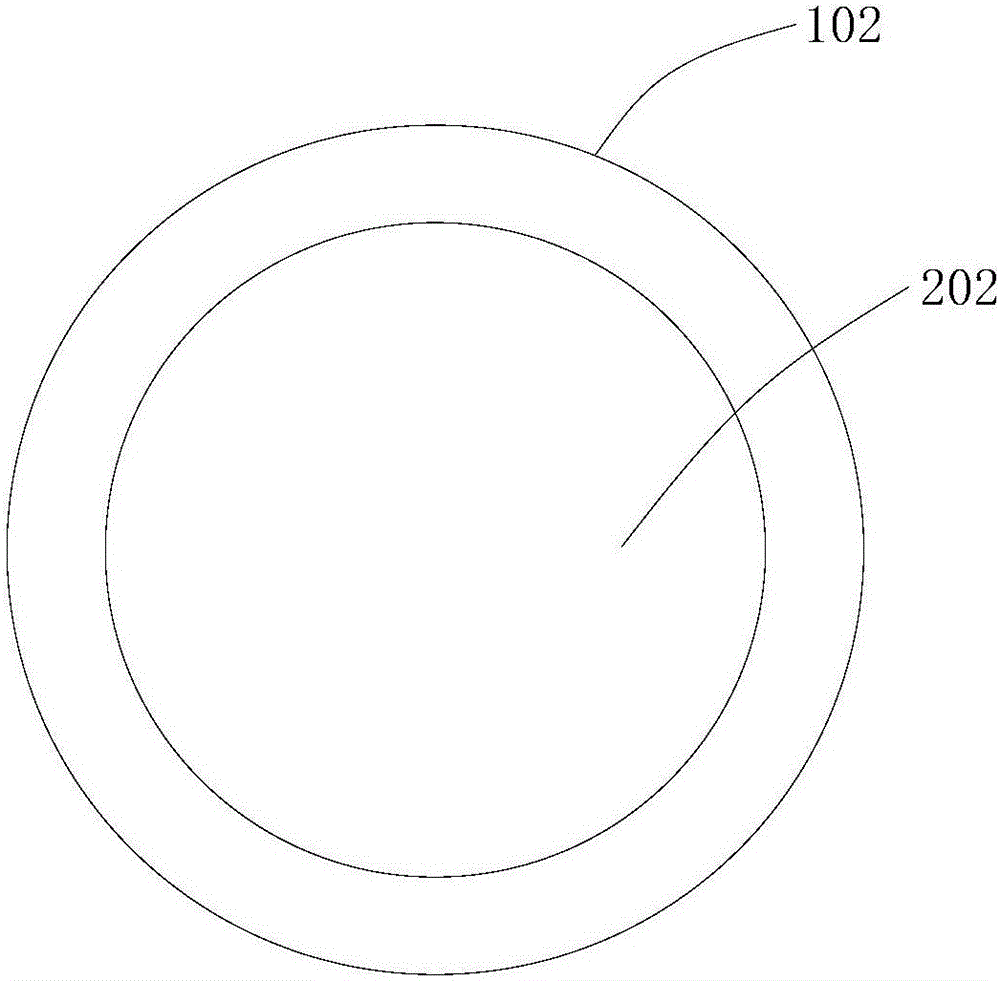

Device for testing electrical performance of electrode material of lithium ion battery, and battery manufacturing method

An electrical performance testing, lithium-ion battery technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of complex testing process, waste of materials, waste of materials, etc. The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Compared with the full battery test, the half battery test lacks the evaluation of cycle performance test, high and low temperature test and real capacity test. However, the full battery test has a complicated process and high cost. General battery material manufacturers seldom conduct full battery performance tests, and their customers often perform performance evaluations. This makes the evaluation cycle very long and the cost of one evaluation is high; conventional full batteries During the performance test, a large amount of raw materials are needed, including aluminum foil, copper foil, tabs, tapes, battery casings, etc.; at the same time, there are many and complicated equipment required, including tab welding machines, winding machines, laser welding, Slitting machine, etc.; the amount of corresponding raw and auxiliary materials is also very large; because of the complicated process, there is a lot of waste caused by defective products in the production process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com