System for reducing failure probability of maintenance personnel and method thereof

A technology of error probability and maintenance personnel, which is applied in the field of electronic information to prevent operator errors, improve production efficiency, and ensure the safety of industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

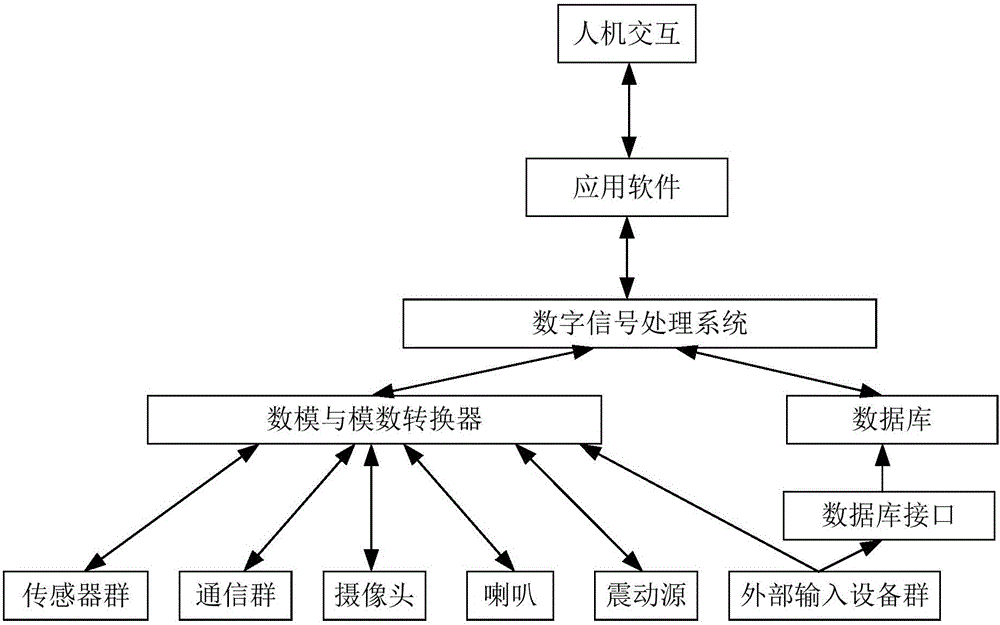

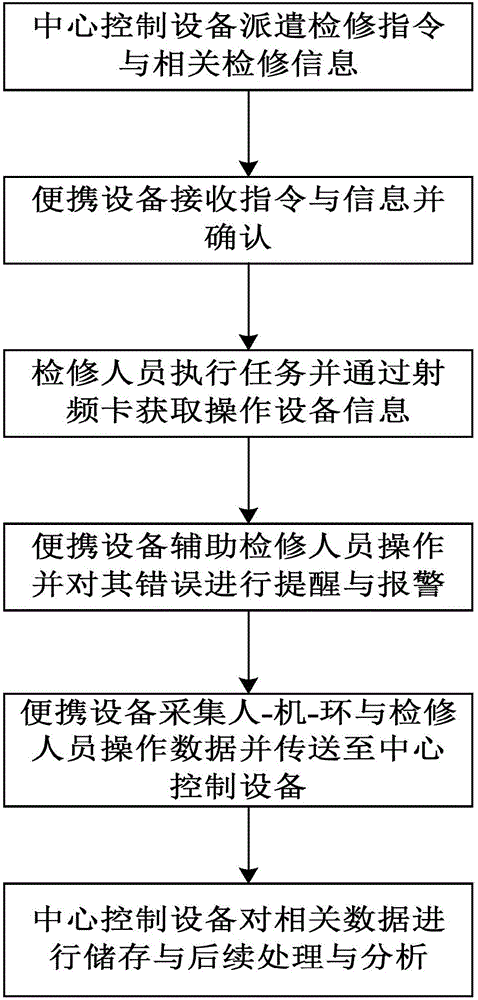

[0031] The technical solution of the present invention is: use portable equipment to assist maintenance personnel with full names, use GPS positioning system to perform real-time positioning and automatic assessment for maintenance personnel; use radio frequency identification technology to electronically identify key processes that are prone to human errors in maintenance links, and realize Real-time reminders and error alarms for maintenance personnel; implanting advanced human factor technology to collect human error data of maintenance personnel to achieve effective evaluation of their work performance.

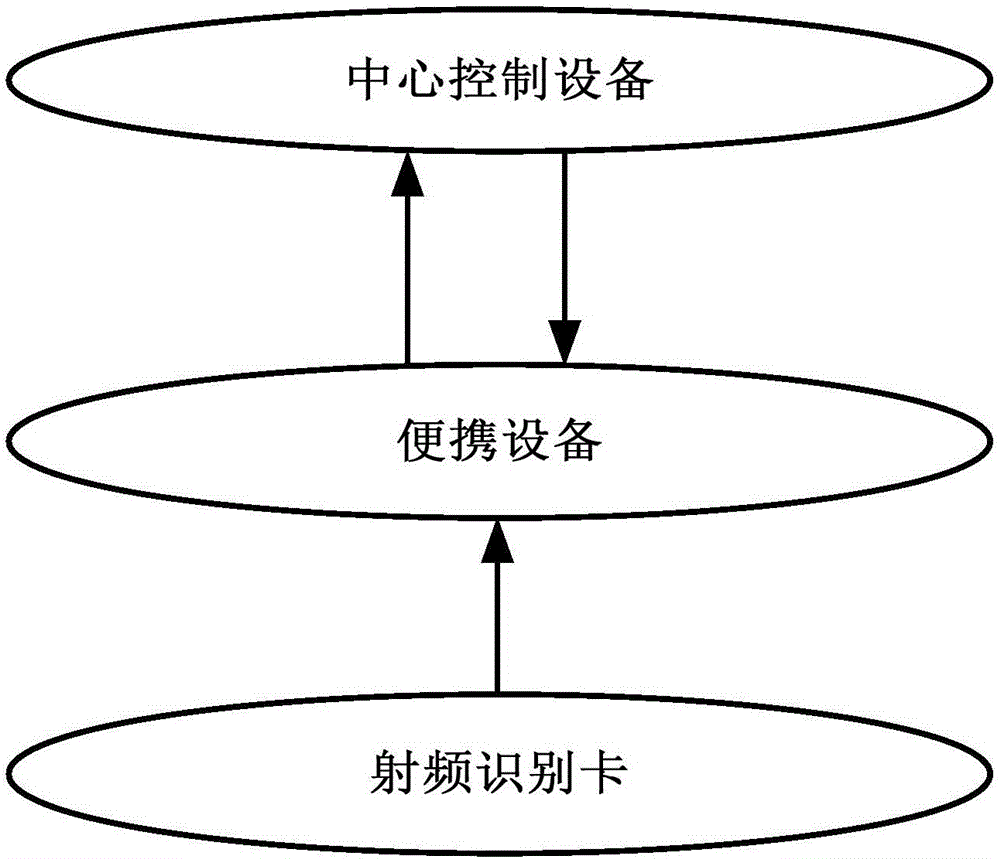

[0032] The specific structure of the automation system involved in the present invention includes: a central control device, a portable device and a radio frequency identification card.

[0033] Among them, the central control equipment and portable equipment are interconnected through other wireless communication methods such as 4G network or satellite communication netwo...

Embodiment 2

[0044] There is a maintenance task T in a factory that needs to be completed by an employee A. This maintenance task has n steps: S1, S2, S3...Sn. The operator can only enter the next step after completing the current step correctly. Otherwise, the operator needs to repeat this step The operator needs to complete the operation task according to the order of the steps, and the time for the employee to complete each step is T1, T2, T3...Tn. From the calculation formula, the total error probability P of this task is:

[0045] P=p 1 +(1‐p 1 )p 2 +(1‐p 1 )(1‐p 2 )p 3 +…+(1‐p 1 )(1‐p 2 )…(1‐p n‐1 )p n , where: P 1 ,P 2 ,P 3 …P n are respectively the error probabilities of operation step S1, operation step S2, operation step S3... and operation step Sn.

[0046] p 1 ,p 2 ,p 3 …p n The calculation formula can be obtained according to the relevant data of human factor technology where: t n is the time the employee actually completes step n, T n The specified time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com