Common turnip beverage and preparation method thereof

A production method and technology of coriander root, applied in the field of beverages, can solve the problems of poor flavor of coriander root drink, waste of coriander root resources, low purchasing power, etc., and achieve the effects of promoting consumption and purchasing, being convenient to carry and easy to accept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

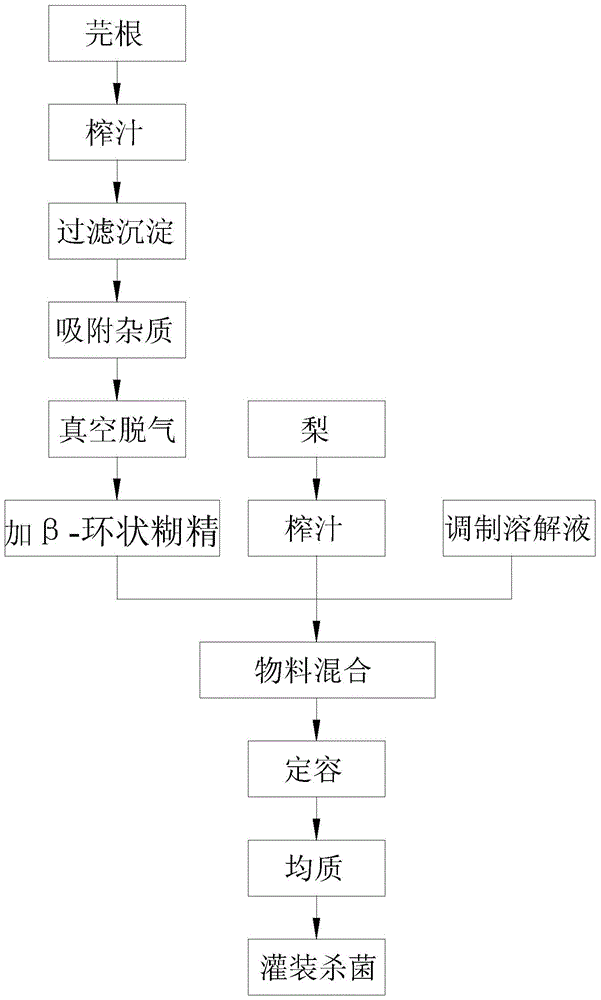

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 of the present invention provides a coriander root beverage, which mainly includes the following raw materials in parts by weight: 20 parts of vacuum degassed coriander root juice, 3 parts of white sugar, 6 parts of maltose, 0.2 part of citric acid and 36.2 parts of water.

[0034]The present embodiment also provides the preparation method of above-mentioned coriander root beverage, comprises the following steps:

[0035] a. Select fresh coriander roots free from diseases and insect pests, wash the coriander roots and squeeze the juice to obtain coriander root juice;

[0036] b. Put coriander root juice at -0.14MPa for 15 minutes to complete vacuum degassing;

[0037] c. Mix the coriander root juice after vacuum degassing with white sugar, maltose, citric acid, and water to obtain a mixed solution, then homogenize the mixed solution at 38°C and 10MPa, fill it, and use it at 80°C Pasteurization for 15 minutes.

Embodiment 2

[0039] Embodiment 2 of the present invention provides a coriander root beverage, which mainly includes the following raw materials in parts by weight: 40 parts of vacuum degassed coriander root juice, 6 parts of white sugar, 9 parts of maltose, 0.26 parts of citric acid, 0.2 parts of β-cyclodextrin, 0.06 parts of sodium D-isoascorbate, 0.06 parts of sodium citrate and 70.68 parts of water.

[0040] The present embodiment also provides the preparation method of above-mentioned coriander root beverage, comprises the following steps:

[0041] a. Select fresh coriander roots free from diseases and insect pests, wash the coriander roots and squeeze the juice to obtain coriander root juice;

[0042] b. Put coriander root juice at -0.14MPa for 15 minutes to complete vacuum degassing;

[0043] c. Add β-cyclodextrin to the coriander root juice after vacuum degassing, and then let the coriander root juice added with β-cyclodextrin stand at 43°C for 1 hour;

[0044] d. Divide the water...

Embodiment 3

[0048] Embodiment 3 of the present invention provides a coriander root beverage, which mainly includes the following raw materials in parts by weight: 30 parts of coriander root juice degassed in vacuum, 5 parts of white sugar, 7 parts of maltose, 0.23 parts of citric acid, 0.2 parts of γ-cyclodextrin, 6 parts of orange juice, 0.1 parts of sodium citrate and 51.47 parts of water.

[0049] The present embodiment also provides the preparation method of above-mentioned coriander root beverage, comprises the following steps:

[0050] a. Select fresh coriander roots free from diseases and insect pests, wash the coriander roots, cut into pieces and squeeze the juice to obtain coriander root juice;

[0051] b. Let the coriander root juice stand at room temperature for 30 minutes, and then use a 220-mesh filter cloth to filter the settled precipitate to obtain the filtered juice, then place diatomaceous earth on the filter paper, and pour the filtered juice to obtain the clear liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com