Tea-flavor surimi snack food and method for preparing same

A technology for leisure food and tea-flavored fish, which is applied in the directions of food ingredients, food shaping, and food ingredient functions. Good effect and fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

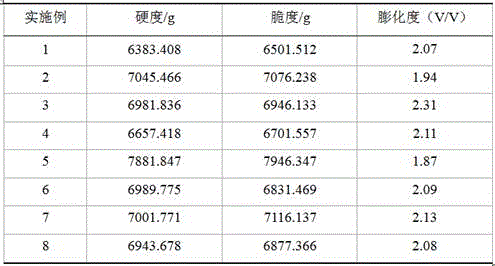

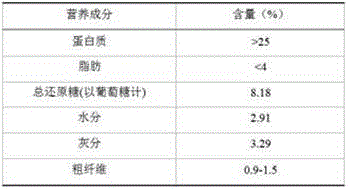

Examples

Embodiment 1

[0035] (1) Pretreatment of raw and auxiliary materials: Thaw 100g of frozen silver carp surimi at 5°C, and place the thawed surimi in a crushing machine for 4 minutes; mix Tieguanyin tea powder, jasmine tea powder and Lapsang Souchong black tea The mass ratio of tea powder is 11:6:7 and mixed, and after superfine pulverization, composite tea powder is obtained, which is set aside;

[0036] (2) Salt beating: add 2.5wt% salt to the surimi processed in step (1), and continue beating for 8 minutes to fully dissolve the salt-soluble protein and obtain viscous surimi raw materials;

[0037] (3) Mixing material: Add 45wt% cornstarch, 3wt% compound tea powder, 0.6wt% baking soda, 2.2wt% white sugar and 50wt% water to the surimi processed in step (2), and stir for 12 minutes until a viscoelastic mixture;

[0038] (4) Forming: Knead the mixture obtained in step (3) repeatedly to ensure that the air in the center is exhausted and there are no large holes before kneading into a round bar...

Embodiment 2

[0047] (1) Pretreatment of raw and auxiliary materials: Thaw 100g of frozen silver carp surimi at 10°C, and place the thawed surimi in a hollow grinding machine for 3 minutes; mix Tieguanyin tea powder, jasmine tea powder and Lapsang Souchong black tea The mass ratio of tea powder is 12:5:6 and mixed, and after ultrafine pulverization, composite tea powder is obtained, which is set aside;

[0048] (2) Salt beating: add 2.0wt% salt to the surimi processed in step (1), and continue beating for 5 minutes to fully dissolve the salt-soluble protein and obtain viscous surimi raw materials;

[0049] (3) Mixing material: Add 35wt% cornstarch, 4wt% compound tea powder, 0.8wt% baking soda, 2.5wt% white sugar and 60wt% water to the surimi treated in step (2), and stir for 10 minutes until a viscoelastic mixture;

[0050] (4) Forming: Knead the mixture obtained in step (3) repeatedly to ensure that the air in the center is exhausted and there are no large holes, and then knead it into a ...

Embodiment 3

[0060] (1) Pretreatment of raw and auxiliary materials: Thaw 100g of frozen silver carp surimi at 4°C, and place the thawed surimi in a hollow grinding machine for 3 minutes; mix Tieguanyin tea powder, jasmine tea powder and Lapsang Souchong black tea The mass ratio of tea powder is 10:7:6 and mixed, and after ultrafine pulverization, composite tea powder is obtained, which is set aside;

[0061] (2) Salt beating: add 3.0wt% salt to the surimi processed in step (1), and continue beating for 5 minutes to fully dissolve the salt-soluble protein and obtain viscous surimi raw materials;

[0062] (3) Mixing material: add 30wt% cornstarch, 1wt% compound tea powder, 0.6wt% baking soda, 2.3wt% white sugar and 50wt% water to the surimi processed in step (2), and stir for 15 minutes until it forms viscoelastic mixture;

[0063] (4) Forming: Knead the mixture obtained in step (3) repeatedly to ensure that the air in the center is exhausted and there are no large holes, and then knead it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crispness | aaaaa | aaaaa |

| Crispness | aaaaa | aaaaa |

| Crispness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com