Cutting device of eight-station cold heading machine

A cold heading machine, eight-station technology, applied in the direction of operating devices, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problem of affecting the processing efficiency of cold heading machines, processing accuracy, shearing devices cannot operate synchronously, and shearing actions Insufficient cutting accuracy and other problems, to achieve the effect of low manufacturing cost, reduced loss, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

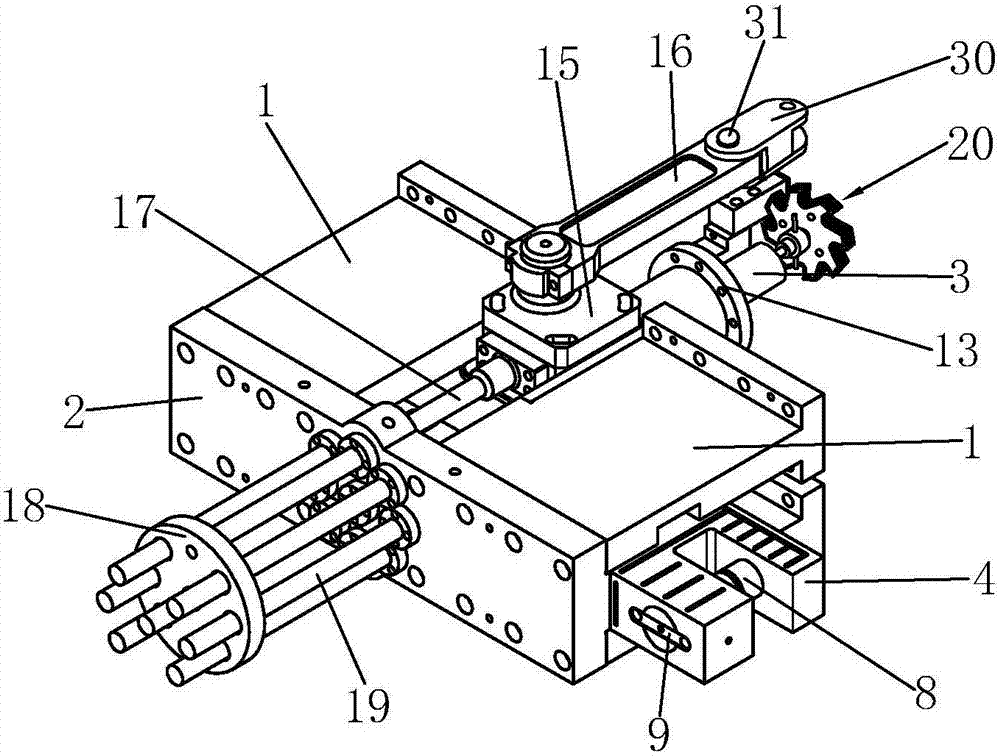

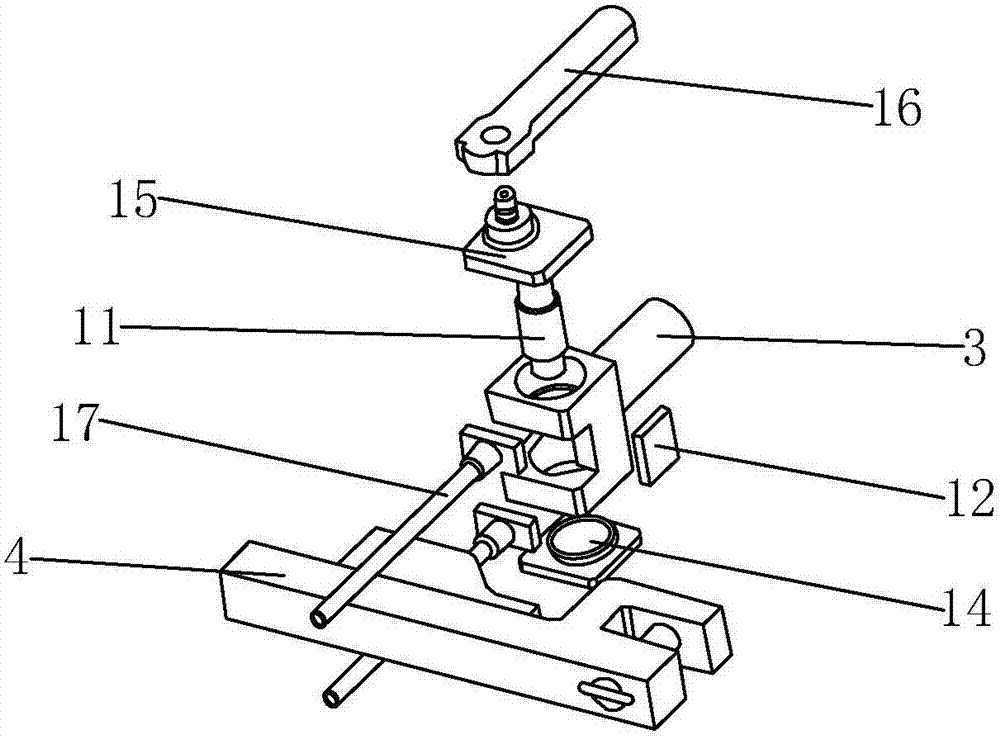

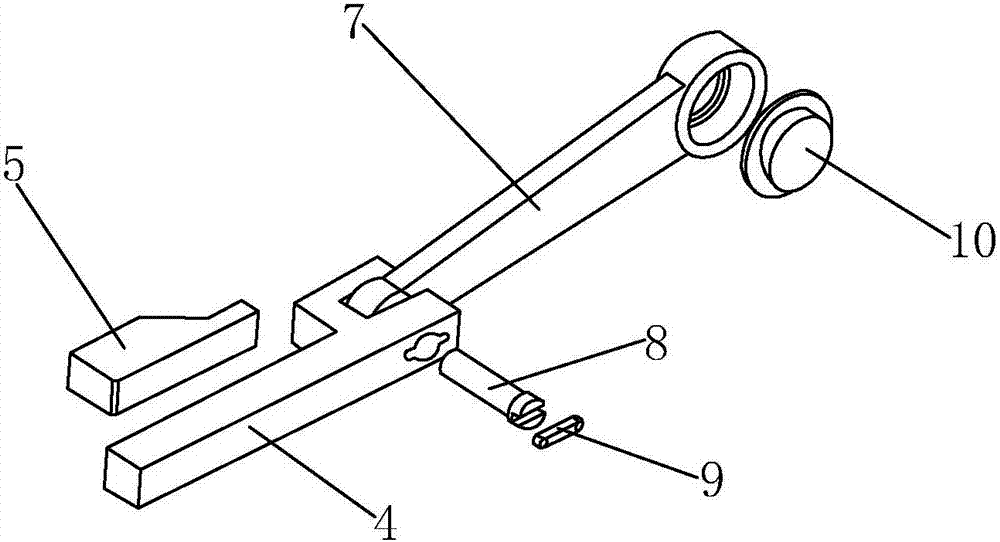

[0031] like Figure 1 to Figure 8As shown, it is the shearing device of the eight-station cold heading machine of the present invention, which includes a T-shaped bracket 1, a side slider 2 and a shearing mechanism. Symmetrical distribution, a total of four T-brackets 1, in order to reduce weight, T-bracket 1 is made of light aluminum material, the surface is treated with professional electroplating and baking paint, smooth, beautiful and stable. The shearing mechanism is arranged between four T-shaped brackets 1. The shearing mechanism includes a cutter cylinder 3, a partial slider 4 and an S-shaped guide plate 5. One side of the T-shaped bracket 1 is provided with a liner 6, and the cutter The barrel 3 is fixedly connected to the liner 6, which increases the stability of the cutter barrel 3 fixed on the T-shaped bracket 1, and ensures the overall stability. It is very convenient for maintenance and replacement without disassembling the whole machine, and the operation is sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com