Working state remote monitoring system for steel cord rubber belt conveyor

A technology of remote monitoring system and belt conveyor, which is applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., which can solve the problems of vulnerability to harsh environments, high labor intensity of staff, and failure to consider safety performance. Achieve the effect of improving safety, high working stability and reliability, saving manpower and material resources for maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

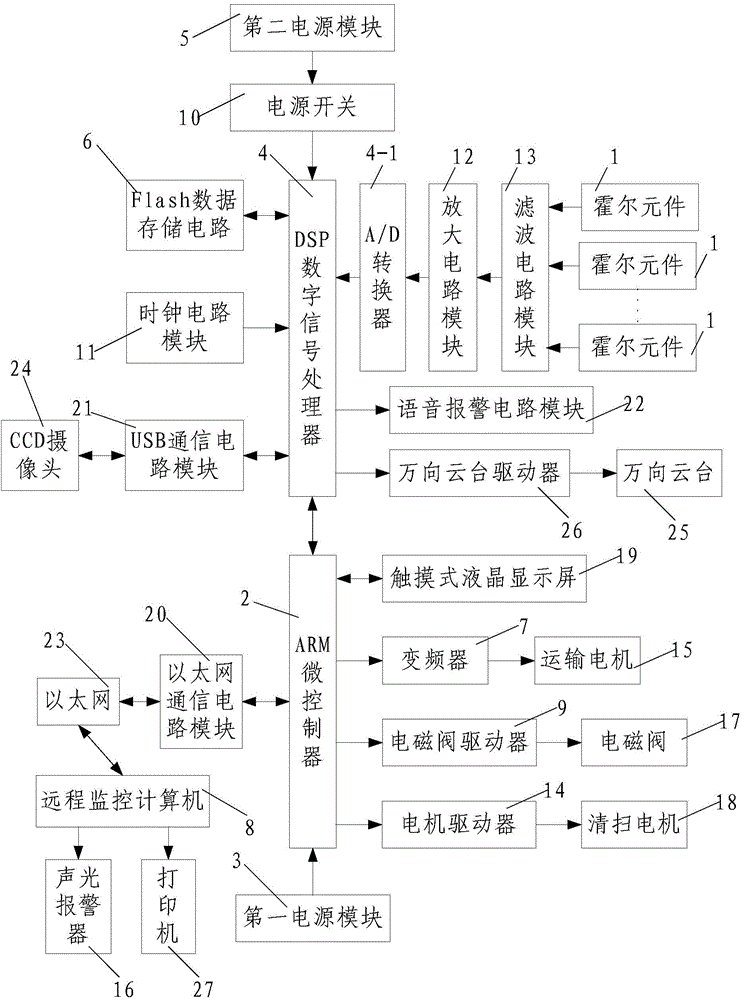

[0031] like figure 1 As shown, the remote monitoring system for the working state of the steel cord belt conveyor of the present invention, the steel cord belt conveyor includes a steel cord belt, a transport motor 15 for driving the steel rope belt to transport goods, an overturning device and a cleaning device, The overturning device is controlled by the overturning hydraulic cylinder, and the oil supply circuit of the overturning hydraulic cylinder is connected with a solenoid valve 17, and the cleaning device is driven by a cleaning motor 18 to realize the cleaning function; the working state of the steel cord belt conveyor is remote The monitoring system includes a remote monitoring computer 8, a main control circuit of the steel cord tape conveyor and a fault detection circuit of the steel cord tape connected to the main control circuit of the steel cord tape conveyor, and the remote monitoring computer 8 is connected with an audible and visual alarm 16 and a printer 27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com