Glass, glass material for pressing moulding,optical member blank and optical membe

A technology of optical components and glass, applied in optical components, optics, instruments, etc., to achieve excellent homogeneity and acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

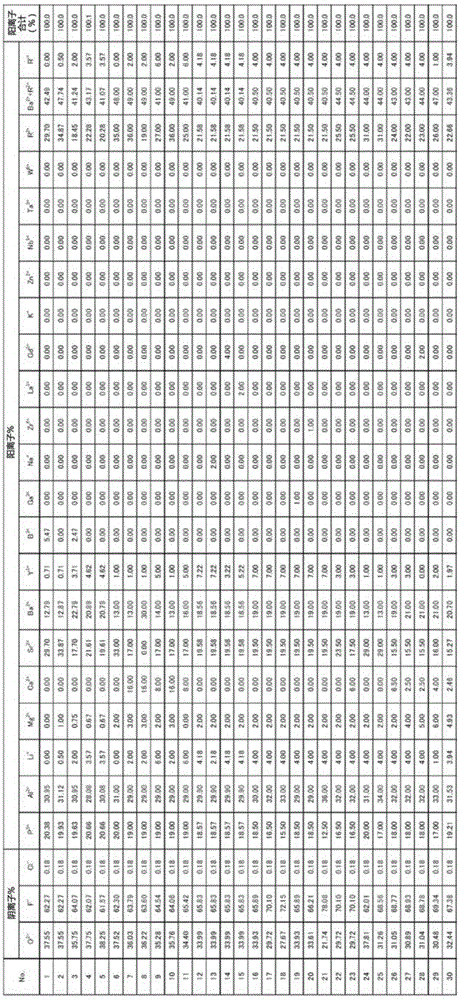

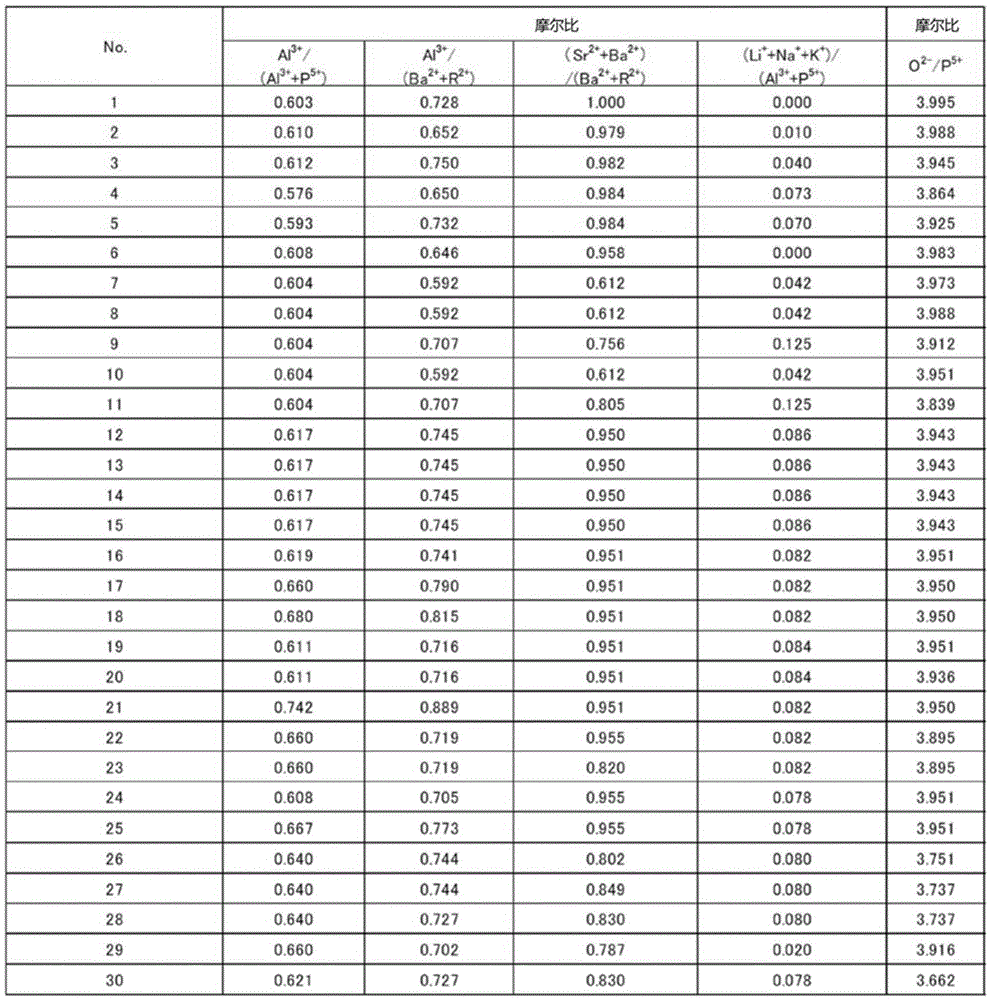

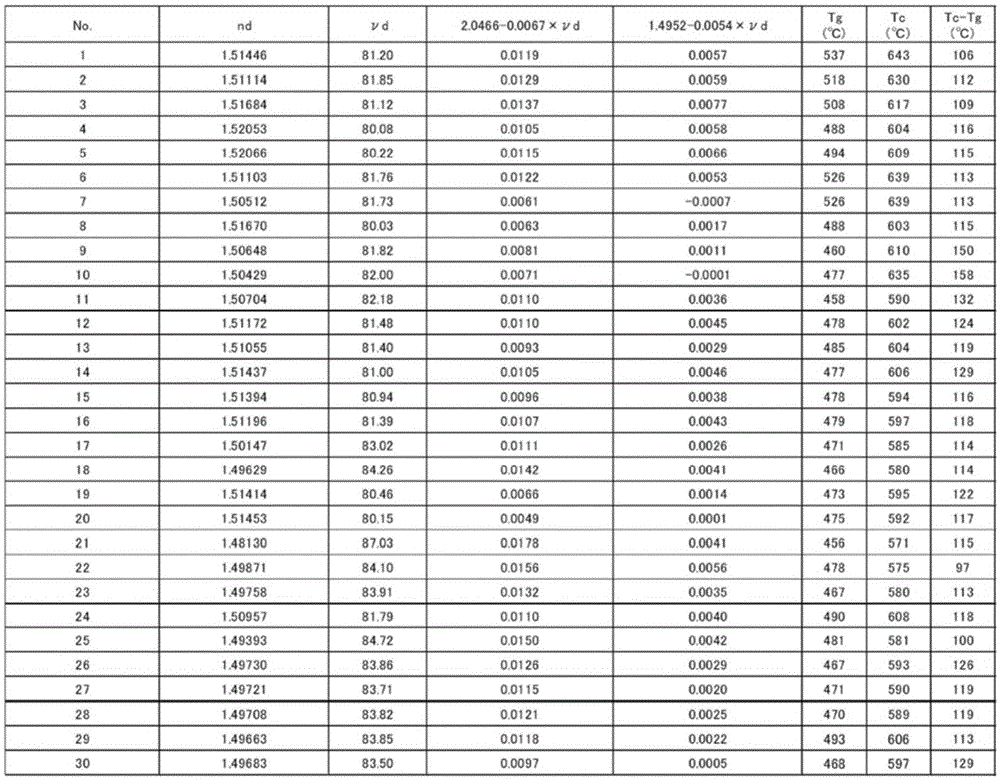

[0120] Hereinafter, the present invention will be further described based on examples. However, this invention is not limited to the form shown to an Example.

[0121] 1. Production and evaluation of glass No.1 to No.30

[0122] In such a way that the glass with the composition shown in Table 1 can be obtained, weigh 100 to 300 g of glass raw materials such as phosphates, fluorides, and oxides corresponding to each glass component in a prescribed ratio, and mix them well to prepare a batch material. The preparation batch is put into a platinum crucible and covered with a lid, and melted in air or nitrogen environment for 1 to 3 hours at 850 to 1200° C. while stirring. After melting, pour the molten glass into a carbon mold of 40×70×15mm, put it into the annealing furnace immediately after cooling to the glass transition temperature, and perform annealing in the glass transition temperature range for about 1 hour. Each glass which has the composition of No.1-No.30 was obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com