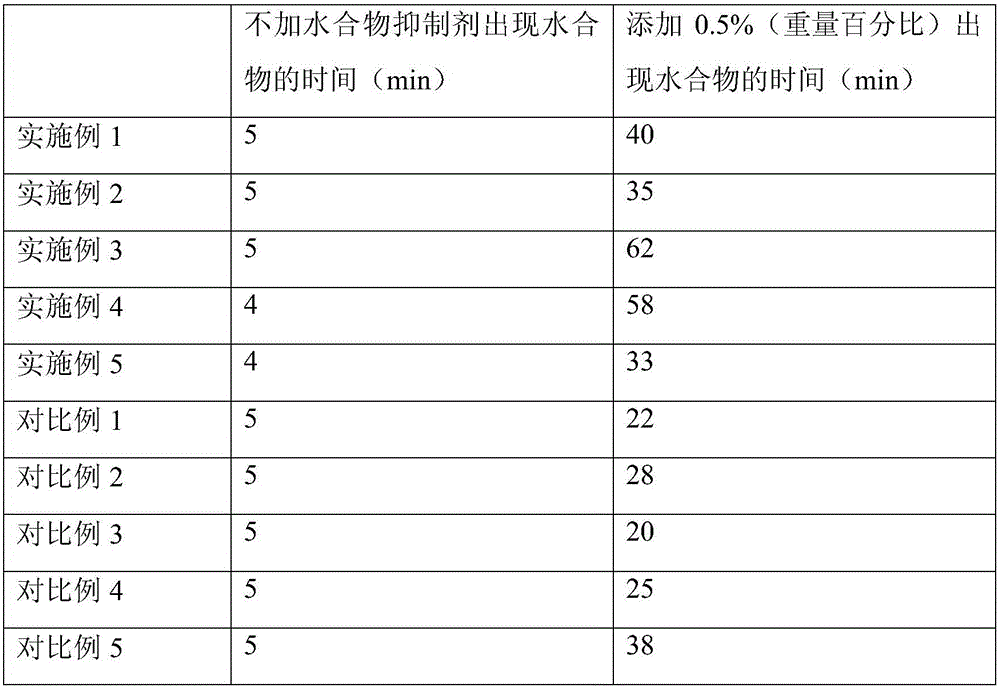

Environment-friendly high-performance kinetic hydrate inhibitor and synthetic method thereof

A hydrate inhibitor and kinetic technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low cost, low dose, small environmental impact, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kinetic hydrate inhibitor, the preparation method comprising the following steps:

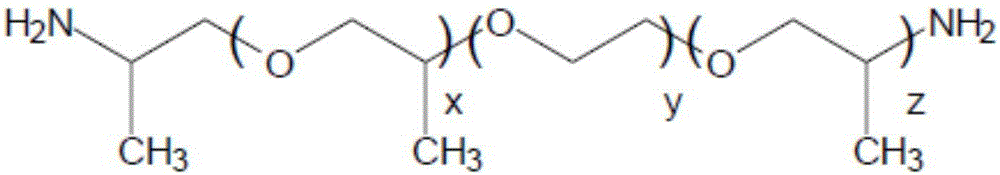

[0042] (1) Allyl polyoxyethylene polyoxypropylene epoxy ether (m=2, n=2, purchased from Hangzhou Diweilai Trading Co., Ltd.) and polyetheramine (x=2, y=2, z =2, Suzhou Changke Industrial Co., Ltd.) mixed with a molar ratio of 2.05:1, that is, 66.2g allyl polyoxyethylene polyoxypropylene epoxy ether (m=2, n=2) and 20g polyetheramine ( x=2, y=2, z=2) were reacted at 80°C for 14 hours to obtain 82.7 g of allyl polyetheramine intermediate, which was a colorless transparent liquid;

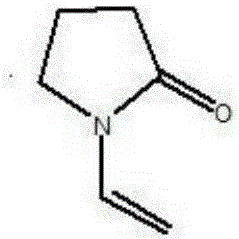

[0043] (2) The allyl polyetheramine intermediate obtained in step (1) and vinylpyrrolidone (purchased from Aladdin Reagent (Shanghai) Co., Ltd.) were reacted in the presence of isopropanol for 10 minutes at a molar ratio of 0.1:10 Hours, that is, 82.7g of allyl polyetheramine intermediate and 555g of allylpyrrolidone reacted for 10 hours in the presence of 641ml of isopropanol, the whole reaction was carried o...

Embodiment 2

[0046] The preparation method of the kinetic hydrate inhibitor of the present invention is characterized in that the method comprises the following steps:

[0047] (1) Allyl polyoxyethylene polyoxypropylene epoxy ether (m=3, n=5, purchased from Changzhou Fiber Dyeing Auxiliary Co., Ltd.) and polyetheramine (x=1, y=3, z =10, purchased from Wuxi Akeli Technology Co., Ltd.) and mixed at a molar ratio of 2.1:1, that is, 53.3g of allyl polyoxyethylene polyoxypropylene epoxy ether (m=3, n=5) and 42.2 g polyetheramine (x=1, y=3, z=10) was reacted at 55° C. for 20 hours to obtain 90.7 g of allyl polyetheramine intermediate, which was a colorless transparent liquid.

[0048] (2) The allyl polyetheramine intermediate obtained in step (1) and vinylpyrrolidone (purchased from Aladdin Reagent (Shanghai) Co., Ltd.) were reacted in the presence of isopropanol for 10 minutes with a molar ratio of 0.5:10 Hours, that is, 90.7g of allyl polyetheramine intermediate and 111g of allylpyrrolidone r...

Embodiment 3

[0051] The preparation method of the kinetic hydrate inhibitor of the present invention is characterized in that the method comprises the following steps:

[0052] (1) Allyl polyoxyethylene polyoxypropylene epoxy ether (m=6, n=8, purchased from Hangzhou Danwei Technology Co., Ltd. AEPH90) and polyetheramine (x=10, y=2, z =10, purchased from Guangzhou Huisheng Chemical Products Co., Ltd. ED600) mixed at a molar ratio of 2.01:1, that is, 81.4g of allyl polyoxyethylene polyoxypropylene epoxy ether (m=6, n=8) and 66.1 g polyetheramine (x=10, y=2, z=10) was reacted at 105° C. for 4 hours to obtain 141.6 g of allyl polyetheramine intermediate, which was a colorless transparent liquid.

[0053] (2) The allyl polyetheramine intermediate obtained in step (1) and vinylpyrrolidone (purchased from Aladdin Reagent (Shanghai) Co., Ltd., allylpyrrolidone) were mixed in isopropyl with a molar ratio of 0.25:10 Reaction in the presence of alcohol for 8 hours, that is, 141.6g of allyl polyether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com