Preparation method of antibiotic plastic

A technology of antibacterial plastics and mixed materials, applied in the field of antibacterial plastics, can solve problems such as easy breeding of bacteria, and achieve the effect of good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

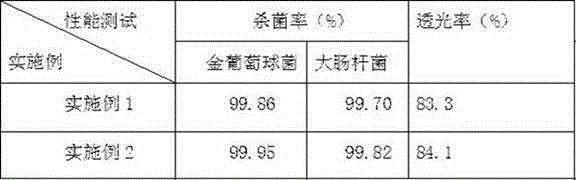

Examples

Embodiment 1

[0017] A antibacterial plastic, including the following weight components: 100 parts of polyzhexyl gemo glycol, 0.4 scent esters of phosphates, 1 part of sorge glycol -shrinking dilatedehyde, and 0.2 copies of silver phosphoric acid.

[0018] The preparation method of antibacterial plastic above, including the following steps:

[0019] A. Polyphyenate ethylene glycolin is drumped and dry for 2 hours at 120 ° C;

[0020] B. Add the polypholic glycolic glycol ester of the step A to the mixer. At the same time, the triatholes, pearl glycol -shrinking diodedehyde, and silver phosphate are added to the mixer at the same time.Mix mixing for 20 minutes to make the ultimate mixture.

[0021] C. Add the ultimate mixture of step B to the dual screw extrusion machine. The processing temperature of the 1 area of the double screw extrusion machine is 255 ° C, the processing temperature of the 260 ° C area in the 2 area is 260 ° C, and the processing temperature of the 3 area is 265 ° C.The pro...

Embodiment 2

[0023] A antibacterial plastic, including the following weight components: 100 parts of polyzhexyl gemo glycol, 0.6 scent of vilurticate, 0.5 parts of pearl alcohol shrinking dietary formaldehyde, and 0.5 parts of silver phosphate.

[0024] The average molecular weight of polypholic glycolitate is 30000g / mol.

[0025] The characteristic viscosity of polypholic acid ethylene glycol is 0.7DL / g.

[0026] A. Polyphyenate ethylene glycolin is drumped and dry for 2 hours at 120 ° C;

[0027] B. Add the polypholic glycolic glycol ester of the step A to the mixer. At the same time, the triatholes, pearl glycol -shrinking diodedehyde, and silver phosphate are added to the mixer at the same time.Mix mixing for 20 minutes to make the ultimate mixture.

[0028] C. Add the ultimate mixture of step B to the dual screw extrusion machine. The processing temperature of the 1 area of the double screw extrusion machine is 255 ° C, the processing temperature of the 260 ° C area in the 2 area is 260 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com