Nano transparent thermal insulation coating and preparation method thereof

A heat-insulating coating and transparent technology, applied in the field of materials, can solve the problems of increasing process difficulty and dispersion time, increasing cost, and affecting the transparency of the coating, so as to suppress ultraviolet radiation damage, reduce energy loss, and improve thermal conductivity. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In a gymnasium, in order to improve heat insulation performance and reduce power consumption, the nano-transparent heat insulation material of Example 1 of the present invention is used to coat the outer wall with glass.

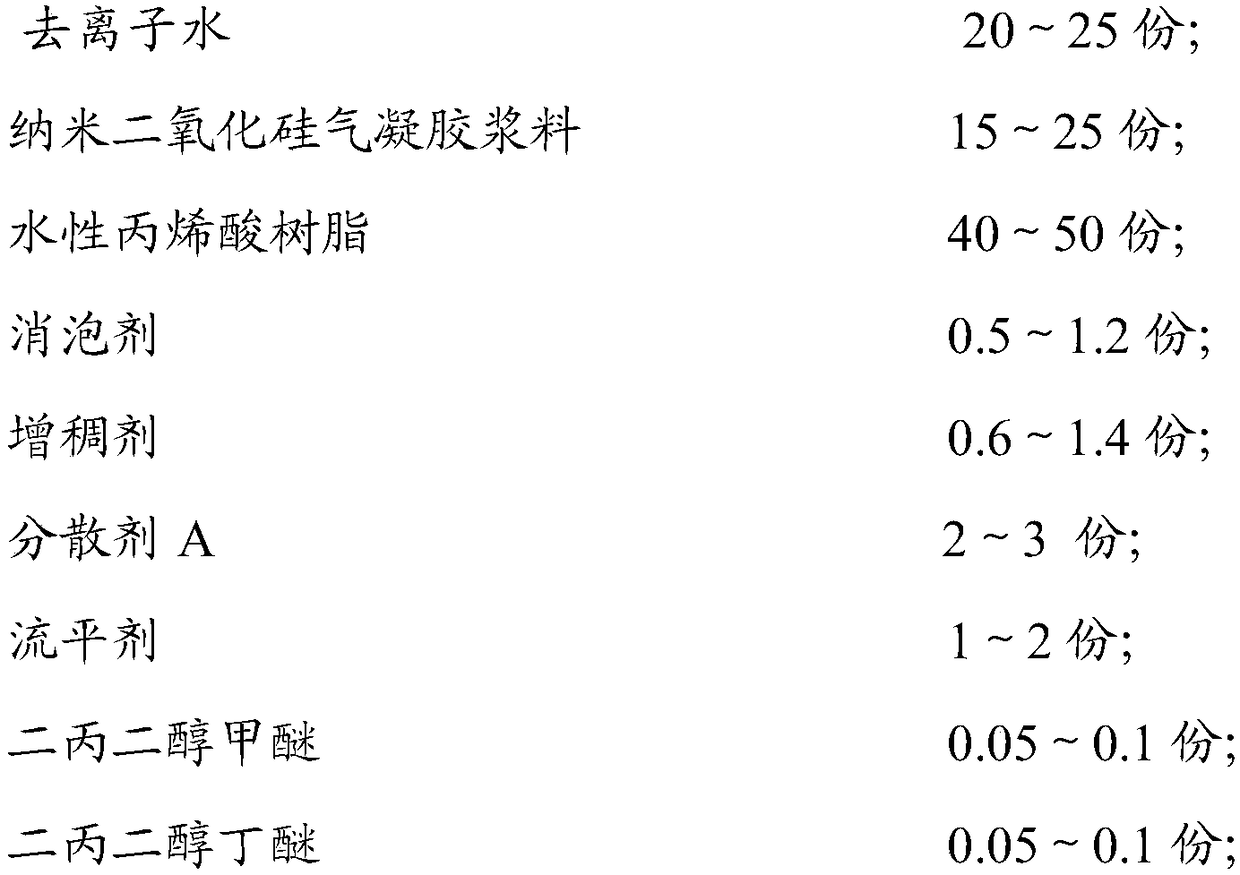

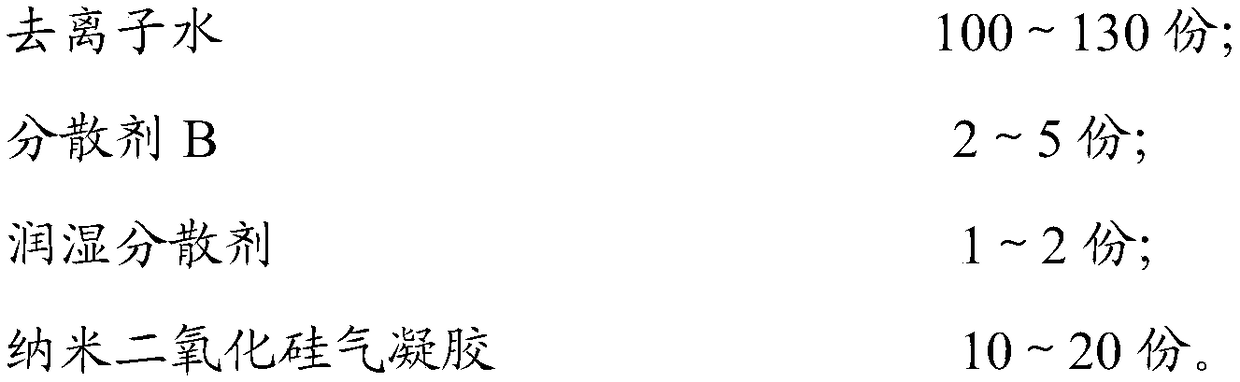

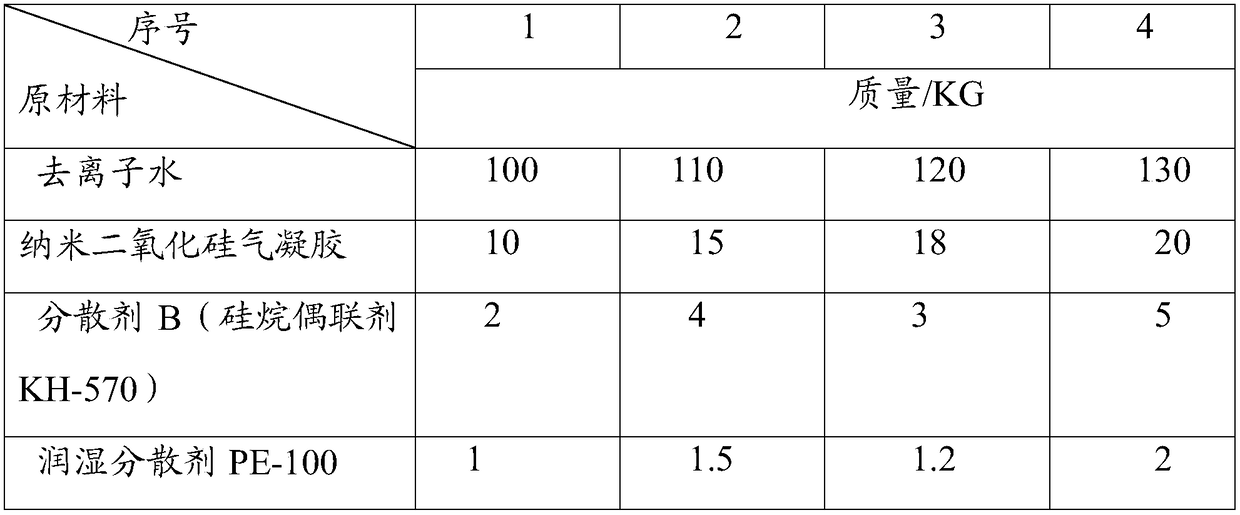

[0052] Concrete formula is as follows: water-based acrylic resin (solid content 50~55%, viscosity is 1100~1600mPa.s (25 ℃)) 45KG, nano-silica airgel slurry 25KG (serial number 1 formula raw material is mixed, adjust pH value at 7.5, disperse on a disperser at high speed for 15 minutes at a speed of 1200rpm, then grind on a grinder for 2 hours at a speed of 3000rpm to obtain a nano-silica airgel slurry with a powder particle size in the range of 30-90nm.), 1053 dispersant (Dispersant A) 3KG, defoamer DP-08 21.2KG, thickener WT-102 1.4KG, leveling agent DP-495 2KG, dipropylene glycol methyl ether 0.1KG, dipropylene glycol butyl ether 0.1KG, deionized water 25KG .

[0053] The preparation method is:

[0054] Mix the above materials, adjust the pH value...

Embodiment 2

[0057] In a large shopping mall, in order to improve the heat insulation performance and increase the light transmittance at the same time, the second nanometer transparent heat insulation material of the present invention is used to coat the glass for the outer wall.

[0058] Concrete formula is as follows: water-based acrylic resin (solid content 50~55%, viscosity is 1100~1600mPa.s (25 ℃)) 50KG, nano-silica airgel slurry (serial number 2 formula raw materials are mixed, and pH value is adjusted at 7.5 , disperse at a high speed on a disperser for 15 minutes at a speed of 1200 rpm, and then grind on a grinder for 3 hours at a speed of 3000 rpm to obtain a nano-silica airgel slurry with a powder particle size in the range of 30 to 90 nm.) 15KG, 1053 dispersants (Dispersant A) 2KG, defoamer DP-08 20.5KG, thickener WT-102 0.6KG, leveling agent DP-495 1KG, dipropylene glycol methyl ether 0.08KG, dipropylene glycol butyl ether 0.08KG, deionized water 20KG .

[0059] The preparati...

Embodiment 3

[0064] In a certain school, in order to insulate heat in summer and improve the learning environment of students, the nano-transparent heat-insulating material of Embodiment 3 of the present invention is used to coat glass on the exterior wall.

[0065] The specific formula is as follows: water-based acrylic resin (solid content 50-55%, viscosity is 1100-1600mPa.s (25°C)) 50KG, nano-silica airgel slurry (serial number 3 formula raw materials are mixed, and the pH value is adjusted at 8.0 , disperse at a high speed on a disperser for 15 minutes at a speed of 1200 rpm, then grind on a grinder for 2 hours at a speed of 3000 rpm to obtain a nano-silica airgel slurry with a powder particle size in the range of 30 to 90 nm.) 20KG, 1053 dispersants (Dispersant A) 2.5KG, defoamer DP-082 1KG, thickener WT-102 1KG, leveling agent DP-495 1.5KG, dipropylene glycol methyl ether 0.1KG, dipropylene glycol butyl ether 0.1KG, deionized water 23KG.

[0066] The preparation method is:

[0067]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com