Wallboard for integral bath room and preparation method of wallboard

A bathroom and integral technology, applied in the field of integral bathroom wall panels and its preparation, can solve the problems of monotonous color, easy pits on the surface, high cost, etc., and achieve the effect of good metal texture, not easy to scratch, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of colloidal particles according to the following formula (mass parts):

[0028] Polyester polyol: 70 parts of ethylene glycol;

[0029] Diisocyanate: 4,4-MDI30 parts;

[0030] Chain extender: 3 parts of hexanediol;

[0031] The polyester polyol, diisocyanate and chain extender are transported to a twin-screw extruder in parts by weight, reacted at a high temperature of 120-150° C., and granulated in water to obtain colloidal granules.

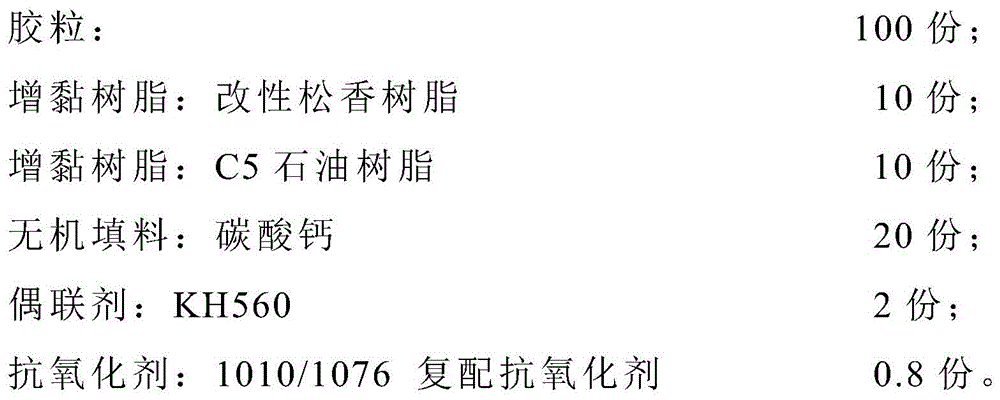

[0032] (2) prepare and prepare film according to following formula (mass parts):

[0033]

[0034] Cooling and drying the granules prepared in step (1), adding tackifying resin, inorganic filler, coupling agent and antioxidant in parts by weight, and casting through a single-screw extruder to obtain a film. The thickness of the adhesive film is controlled at 0.04-0.10mm.

[0035] (3) The above-mentioned adhesive film and the thin aluminum plate with colored texture are combined by a laminating machine, and the tem...

Embodiment 2

[0039] (1) Prepare polyurethane micelle according to following formula (mass parts):

[0040] Polyester polyol: 60 parts of neopentyl glycol;

[0041] Diisocyanate: 2,4-MDI40 parts;

[0042] Chain extender: 5 parts of propylene glycol;

[0043] The polyester polyol, diisocyanate and chain extender are transported to a twin-screw extruder in parts by weight, reacted at a high temperature of 120-150° C., and granulated in water to obtain colloidal granules.

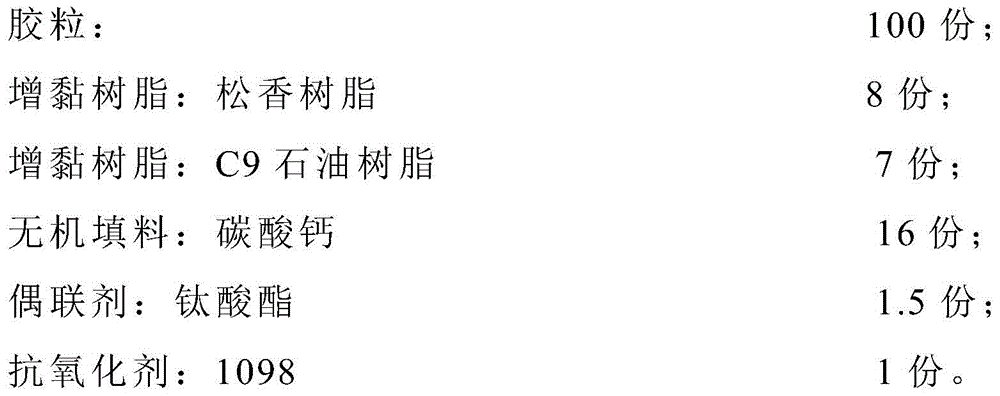

[0044] (2) Prepare polyurethane hot-melt adhesive film according to the following formula (mass parts):

[0045]

[0046] Cool and dry the granules prepared in step (1), then add tackifying resin, inorganic filler, coupling agent and antioxidant in parts by weight, and then flow cast through a single-screw extruder to obtain polyurethane hot melt glue film. The thickness of the adhesive film is controlled at 0.04-0.10mm.

[0047] (2) The above-mentioned adhesive film and the thin aluminum plate with colored texture ...

Embodiment 3

[0051] (1) Prepare polyurethane micelle according to following formula (mass parts):

[0052] Polyester polyol: 80 parts of diethylene glycol;

[0053] Diisocyanate: 20 parts of XDI;

[0054] Chain extender: 6 parts of 1,3-butanediol;

[0055] The polyester polyol, diisocyanate and chain extender are transported to a twin-screw extruder in parts by weight, reacted at a high temperature of 120-150° C., and granulated in water to obtain colloidal granules.

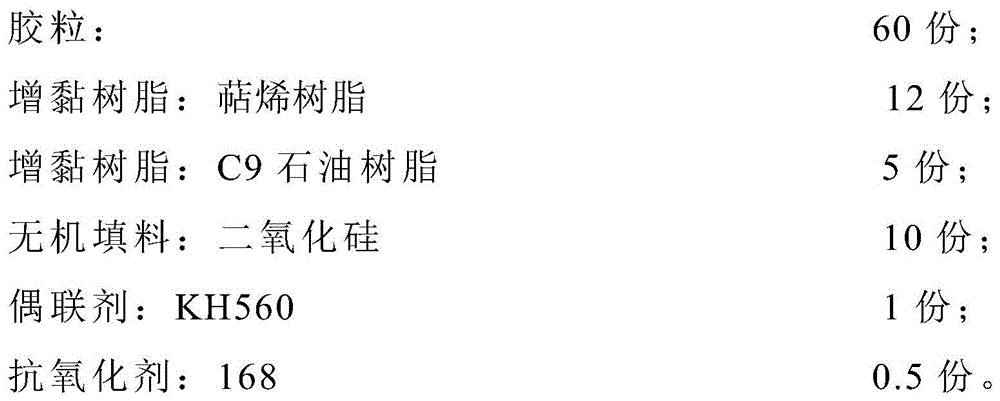

[0056] (2) Prepare polyurethane hot-melt adhesive film according to the following formula (mass parts):

[0057]

[0058] Cooling and drying the granules prepared in step (1), adding tackifying resin, inorganic filler, coupling agent and antioxidant in parts by weight, and casting through a single-screw extruder to obtain a film. The thickness of the adhesive film is controlled at 0.04-0.10mm.

[0059] (3) Composite the above-mentioned adhesive film and the thin aluminum plate with colored texture through a laminating m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com