Tomato seed oil and preparation method thereof

A tomato seed oil and tomato seed technology, which is applied in the fields of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of high oil residue, long extraction time, large solvent consumption, etc., and achieve good economy The effect of value, mature technology and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

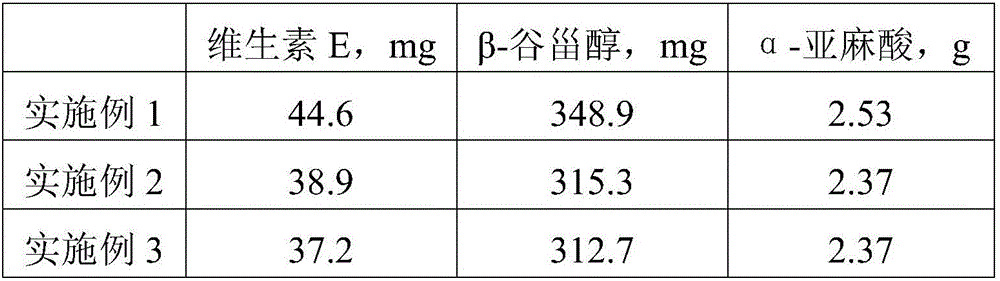

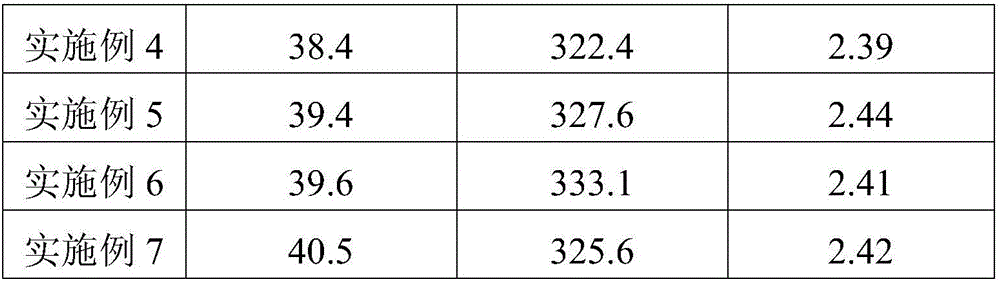

Examples

Embodiment 1

[0032] The preparation method of tomato seed oil comprises the following steps:

[0033] (1) select the tomato seeds produced in the current year, crush them to 40 meshes, put them into a hot air dryer and dry them with 800°C hot air to obtain tomato seeds with a moisture content of 3wt%;

[0034] (2) Extraction of crude oil: the tomato seeds with a moisture content of 3wt% were subjected to supercritical CO 2 Fluid extraction, adding entrainer during the extraction process, in which CO 2 The flow rate is 15kg / h, the flow rate of the entrainer is 0.9kg / h, the extraction pressure is 35Mpa, the extraction temperature is 36°C, and the extraction time is 2h to obtain crude oil;

[0035] (3) Hydration degumming: mix crude oil and acid solution in a mass ratio of 100:5, stir at 300 rpm for 30 minutes, and centrifuge to obtain degummed oil;

[0036] (4) Decolorization: Stir and mix the degummed oil and activated carbon (50 mesh activated carbon produced by Qingdao Jiade Filter Mate...

Embodiment 2

[0042] It is basically the same as Example 1, the difference is only that: in the step (2), the entrainer is composed of 1,2-propanediol and glycerin, wherein the flow rate of 1,2-propanediol is 0.45kg / h, and the flow rate of glycerin is 0.45kg / h. The tomato seed oil of embodiment 2 can be obtained.

Embodiment 3

[0044] It is basically the same as Example 1, the difference is only that: in the step (2), the entrainer is composed of 1,2-propanediol and 1,3-propanediol, wherein the flow rate of 1,2-propanediol is 0.45kg / h, 1, The flow rate of 3-propanediol is 0.45kg / h. The tomato seed oil of embodiment 3 can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com