Wintersweet flower tea preparation method and product thereof

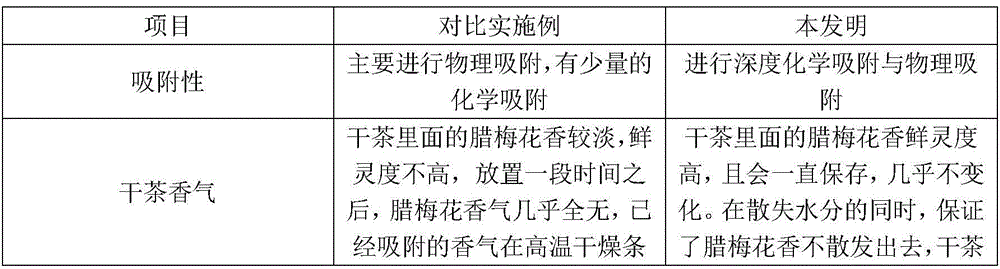

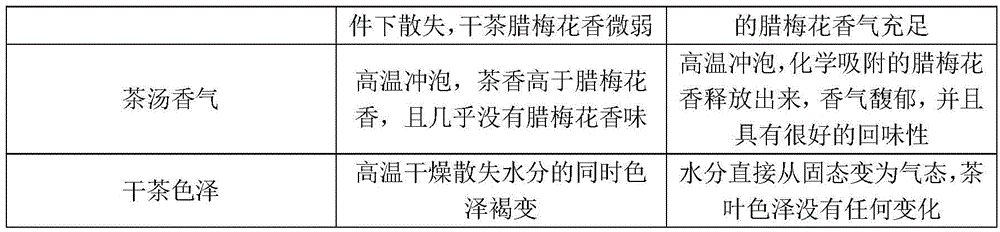

A technology of wintersweet flowers and wintersweet, which is applied in the field of preparation of wintersweet scented tea, the product obtained by the method, can solve the problems of not being resistant to foaming, low aroma, unfavorable tea fragrance absorption, etc., and achieve long-lasting aroma, foam resistance, good absorption of flower fragrance, The effect of high freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of wintersweet scented tea, specifically comprising the steps of:

[0027] (1) tea base selection: select the green tea base with green color, dry the tea base until the water content is 5%, and cool to normal temperature (20-25° C.) for use;

[0028] (2) Wintersweet flower processing: sieve out the unopened green buds and wilted flowers of the wintersweet flower, and do cleaning for subsequent use;

[0029] (3) Camellia splicing: Mix 100g of the selected tea base with 50g of the treated wintersweet flowers evenly, the ratio is 1:0.5;

[0030] (4) Scenting system: After the tea and flowers are evenly mixed, put them into a wooden tea box for scenting; keep 80% full when packing, so that the tea and flowers are loose and natural, and not tightly pressed; the wooden tea box is covered with clean and odor-free For coverings, the scenting temperature is controlled at 10°C, and the scenting time is 28 hours; during the scenting period, the box is turned...

Embodiment 2

[0039] A preparation method of wintersweet scented tea, specifically comprising the steps of:

[0040] (1) tea base selection: select the yellow tea base of orange-yellow color, dry the tea base until the water content is 5%, cool to normal temperature (20-25° C.) for use;

[0041] (2) Wintersweet flower processing: sieve out the unopened green buds and wilted flowers of the wintersweet flower, and do cleaning for subsequent use;

[0042] (3) Camellia splicing: 100g of the selected tea base and 45g of processed wintersweet flowers, the ratio is 1:0.45;

[0043] (4) Scenting system: After the tea and flowers are evenly mixed, put them into a wooden tea box for scenting; keep 80% full when packing, so that the tea and flowers are loose and natural, and not tightly pressed; the wooden tea box is covered with clean and odor-free Covering, the scenting temperature is controlled at 8°C, and the scenting time is 33 hours; during the scenting period, the box is turned over 3 times to...

Embodiment 3

[0052] A preparation method of wintersweet scented tea, specifically comprising the steps of:

[0053] (1) tea base selection: select black tea base with black color, dry the base to a water content of 4%, cool to normal temperature (20-25° C.) for use;

[0054](2) Wintersweet flower processing: sieve out the unopened green buds and wilted flowers of the wintersweet flower, and do cleaning for subsequent use;

[0055] (3) Camellia splicing: 100g of the selected tea base and 35g of processed wintersweet flowers, the ratio is 1:0.35;

[0056] (4) Scenting system: After the tea and flowers are evenly mixed, put them into a wooden tea box for scenting; keep the box 80% full, so that the tea and flowers are loose and natural, and not tightly pressed; the wooden tea box is covered with clean and odor-free Covering, the scenting temperature is controlled at 6°C, and the scenting time is 33 hours; during the scenting period, the box is turned twice to make it evenly scented;

[0057...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com