A kind of extrusion board and preparation method thereof

A technology of extruded plastic board and extrusion molding, which is applied in the field of composite materials, can solve the problems that the thermal insulation effect of modified extruded plastic board cannot be satisfied, and achieve the effect of improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

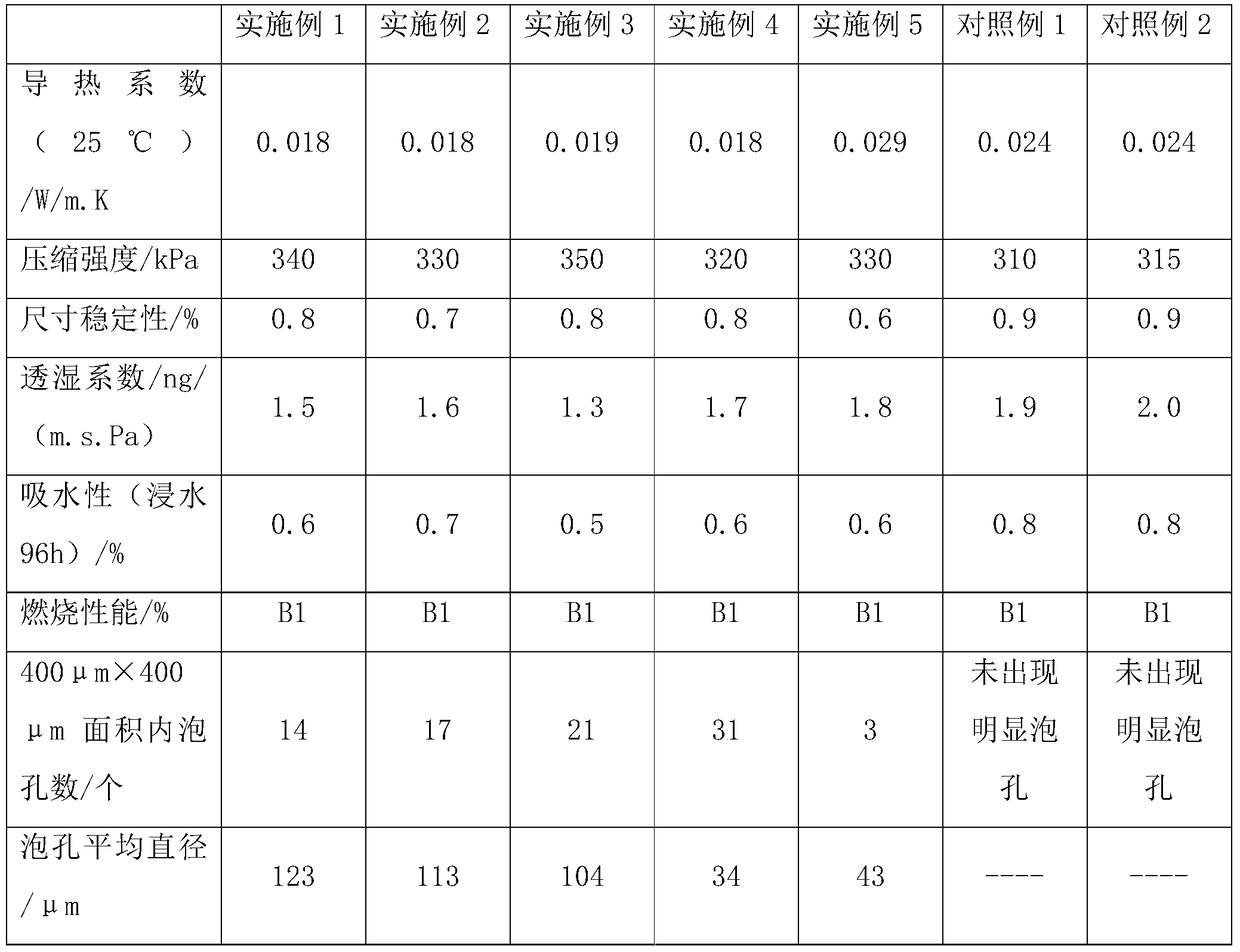

[0048] (1) Add 200g of polystyrene particles, 14.3g of graphite, 12.7g of flame retardant hexabromocyclododecane and additives into the mixing bin for mixing, wherein the additives include 1.4g of aluminum hydroxide and zinc stearate 0.6g, calcium stearate 1.0g, form the first mixture after mixing for 15 minutes; then after the twin-screw equipment is heated to 185 ° C, the first mixture is injected into the twin-screw equipment for stirring, and the foam is added during the stirring process. 20g of foaming agent, 11.6g of ethanol and 10g of ammonium bicarbonate were mixed, heated and stirred for 20 minutes to form the second mixture;

[0049] (2) The second compound is transported to the extrusion port, and the second compound is statically mixed and then dynamically mixed during the transmission process, so that the second compound is mixed more evenly;

[0050] (3) Add the second mixture into the extruder to extrude at 75° C. and form the extruded board of the present inven...

Embodiment 2

[0053] (1) Add 220g of polystyrene particles, 19.0g of graphite, 11.0g of flame retardant hexabromocyclododecane, and additives into the mixing bin for mixing, wherein the additives include 1.2g of aluminum hydroxide, stearic acid 0.8g of zinc and 1.1g of calcium stearate were mixed for 20 minutes to form the first mixture; after the twin-screw equipment was heated to 175°C, the first mixture was injected into the twin-screw equipment for stirring, adding 13.0g of ethanol, blowing agent 18g and 10g of ammonium bicarbonate were mixed and heated and stirred for 20 minutes to form the second mixture;

[0054] (2) The second compound is transported to the extrusion port, and the second compound is statically mixed and then dynamically mixed during the transmission process, so that the second compound is mixed more evenly;

[0055] (3) Add the second mixture into the extruder to extrude at 75° C. and form the extruded board of the present invention.

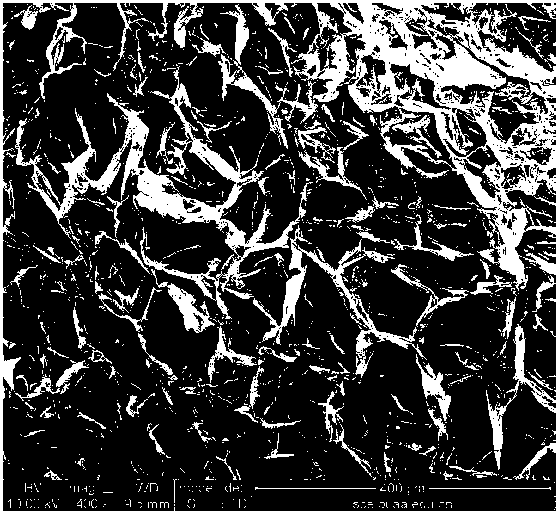

[0056] The surface SEM observ...

Embodiment 3

[0058] (1) Add 180g of polystyrene particles, 15.0g of graphite, 8.0g of flame retardant hexabromocyclododecane, and additives into the mixing bin for mixing, wherein the additives include 0.8g of aluminum hydroxide, stearic acid 0.7g of zinc and 0.8g of calcium stearate were mixed for 20 minutes to form the first mixture; after the twin-screw equipment was heated to 180°C, the first mixture was injected into the twin-screw equipment for stirring, adding 10.0g of ethanol, blowing agent 12g and 10g of ammonium bicarbonate were mixed and heated and stirred for 20 minutes to form the second mixture;

[0059] (2) The second compound is transported to the extrusion port, and the second compound is statically mixed and then dynamically mixed during the transmission process, so that the second compound is mixed more evenly;

[0060] (3) Add the second mixture into the extruder to extrude at 75° C. and form the extruded board of the present invention.

[0061] The surface SEM observa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com