Method for preparing matte dry grain glazed tiles

A dry glaze and matte technology, which is applied in the field of ceramics, can solve the problems of easy dirt sticking, dirt absorption, and strength decline on the surface, and achieve the effects of improving antifouling performance, reducing product defects, and increasing product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

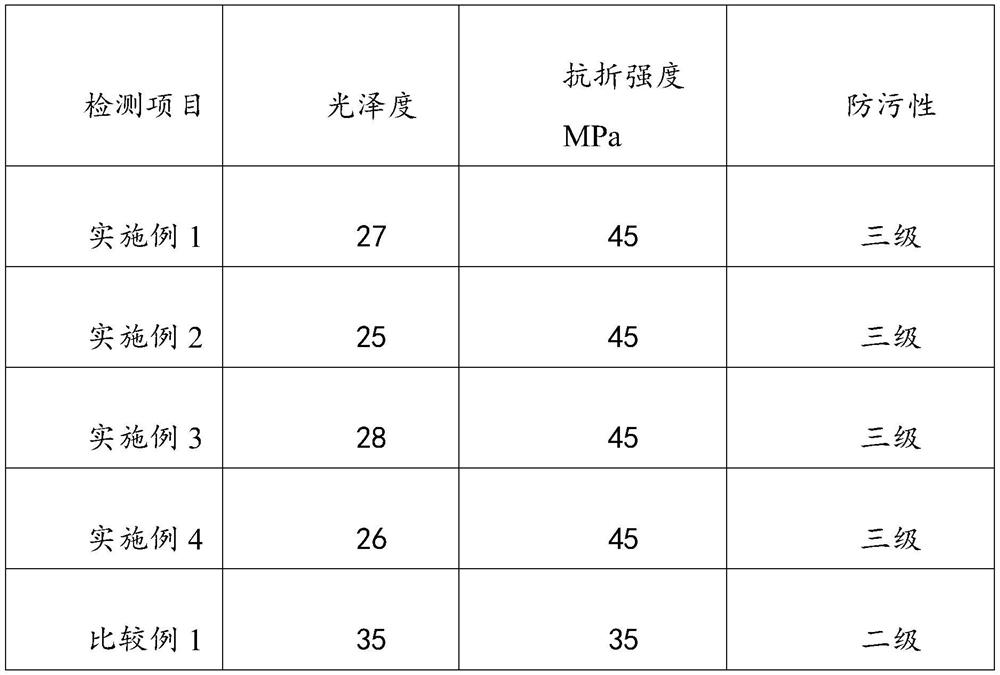

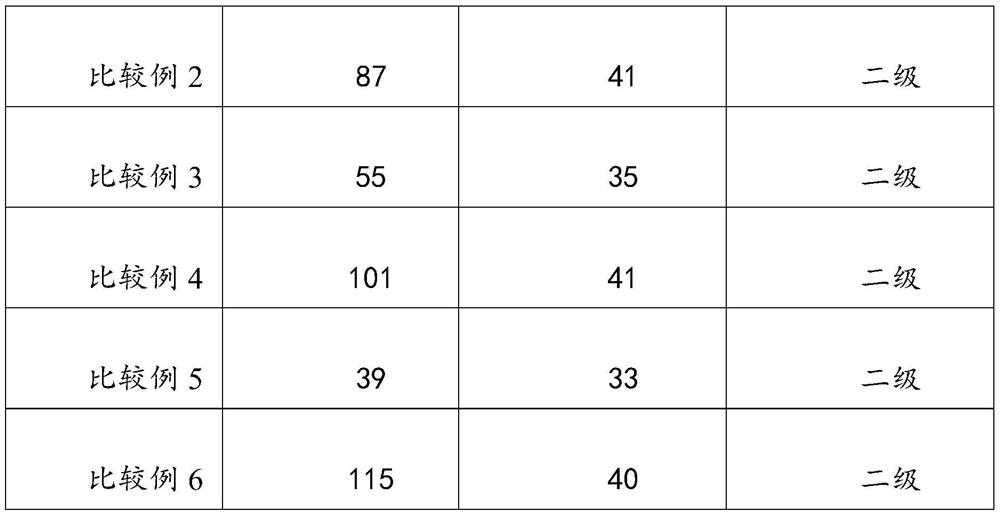

Examples

Embodiment 1

[0032] Follow the steps below to prepare dry grain glazed tiles:

[0033] 1. After the first drying of the bricks laid by the press, the drying temperature is controlled at 90°C and the drying time is 120 minutes to remove the free water inside, so that the moisture content of the bricks is less than 0.5%. A layer of water film is formed on the surface, and the amount of sprayed water mist is 120g / m 2 ;

[0034] 2. Then pour the bottom glaze on the surface of the green body, the amount of glaze is 87g (340*670 tray); the bottom glaze includes SiO in mass percentage 2 40%, Al 2 o 3 15%, CaO10%, MgO8%, ZnO15%, K 2 O6%, Na 2 O3%, BaO3%; then use an inkjet machine to print the pattern, and then dry it in a second drying kiln. The drying temperature is controlled at 200 ° C and the time is 20 minutes;

[0035]3. Spray dry granular glaze; the flow rate of dry granular glaze is 26s, the specific gravity is 1.27g / ml, the amount of glaze is 67g (340*670 tray), and the fineness is...

Embodiment 2

[0042] Follow the steps below to prepare dry grain glazed tiles:

[0043] 1. After the first drying of the adobe made by the press, the drying temperature is controlled at 110°C and the time is 60 minutes to remove the free water inside, so that the moisture content of the adobe is less than 0.5%. After the adobe leaves the drying kiln, spray water on its surface, A layer of water film is formed on the surface, and the amount of sprayed water mist is 140g / m 2 ;

[0044] 2. Then pour the bottom glaze on the surface of the body, the amount of glaze is 93g (340*670 tray); the bottom glaze includes SiO in mass percentage 2 55%, Al 2 o 3 13%, CaO8%, MgO5%, ZnO10%, K 2 O5%, Na 2 O2%, BaO2%; then use an inkjet machine to print the pattern, and then dry it in a second drying kiln. The drying temperature is controlled at 300 ° C and the time is 10 minutes;

[0045] 3. Spray dry granular glaze; the flow rate of dry granular glaze is 31s, the specific gravity is 1.23g / ml, the amoun...

Embodiment 3

[0052] Follow the steps below to prepare dry grain glazed tiles:

[0053] 1. After the first drying of the adobe made by the press, the drying temperature is controlled at 100°C and the time is 130 minutes to remove the free water inside, so that the moisture content of the adobe is less than 0.5%. After the adobe leaves the drying kiln, spray water on its surface, A layer of water film is formed on the surface, and the amount of sprayed water mist is 130g / m 2 ;

[0054] 2. Then pour the bottom glaze on the surface of the green body, the amount of glaze is 90g (340*670 tray); the bottom glaze includes SiO in mass percentage 2 54%, Al 2 o 3 10%, CaO9%, MgO7%, ZnO14%, K 2 O4%, Na 2 O1%, BaO1%; then spray the pattern with an inkjet machine, and then dry it in a second drying kiln. The drying temperature is controlled at 250°C and the time is 15 minutes;

[0055] 3. Spray dry granular glaze; the flow rate of dry granular glaze is 29s, the specific gravity is 1.25g / ml, the am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com