SIP chip and laser device coupling method and optical transceiver module manufactured with same

An optical transceiver module and laser technology, applied in the field of communications, can solve the problems of SIP chips and lasers, unfavorable mass production operations, low production efficiency, etc., and achieve the effects of easy mass production operations, simple structure, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the drawings and embodiments.

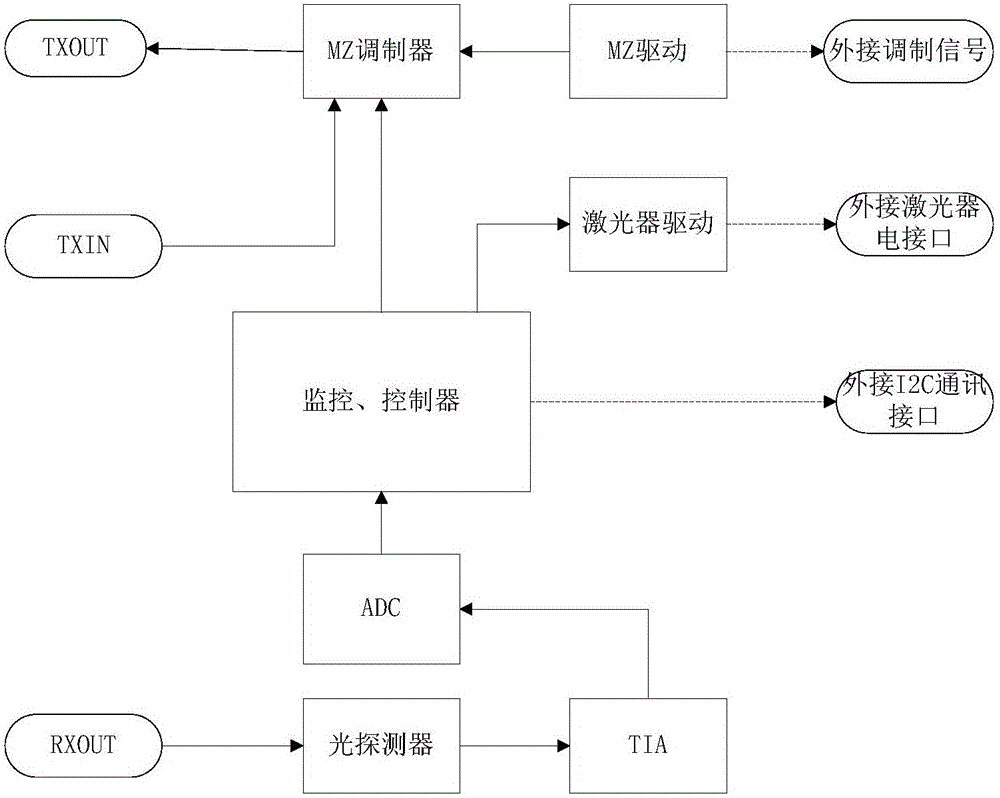

[0047] SIP chip 3 is a silicon-based optoelectronic chip that integrates Mach-Zander (MZ) modulators, photodetectors, and internal diagnostic and control processors in integrated circuits. The internal functional structure of the SIP chip is as follows: figure 1 As shown, it can control the laser to work, and accept external information to modulate the optical signal at 2.5Gpbs-25Gpbs, and can also accept the external 2.5Gpbs-25Gpbs modulated optical information to convert it into an electrical signal.

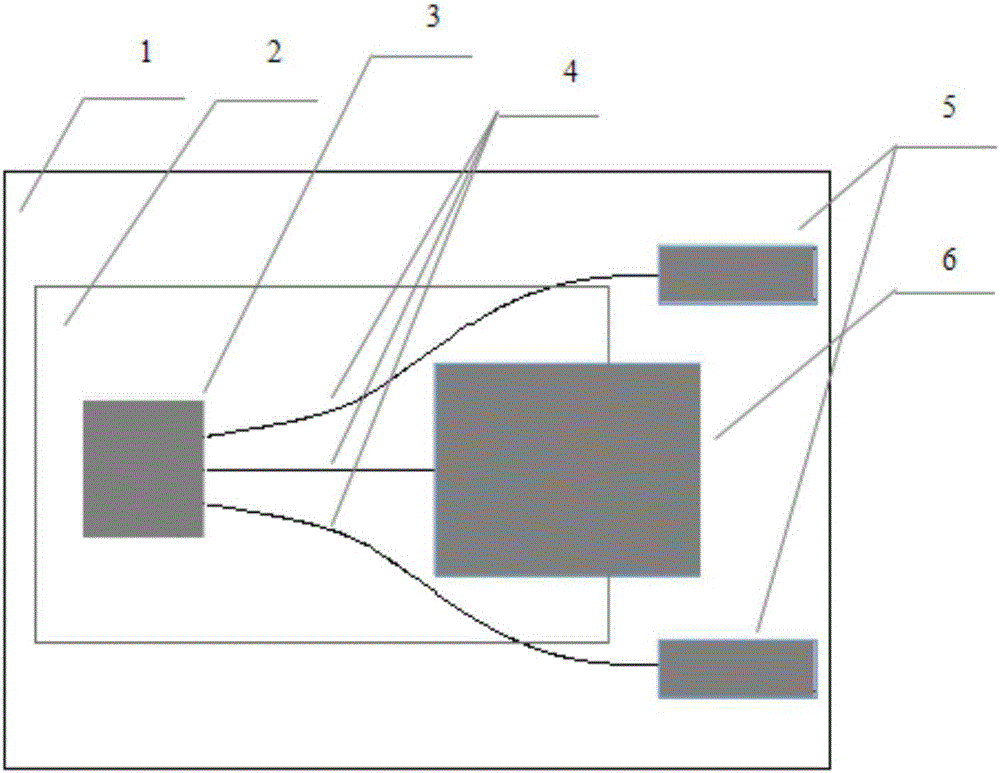

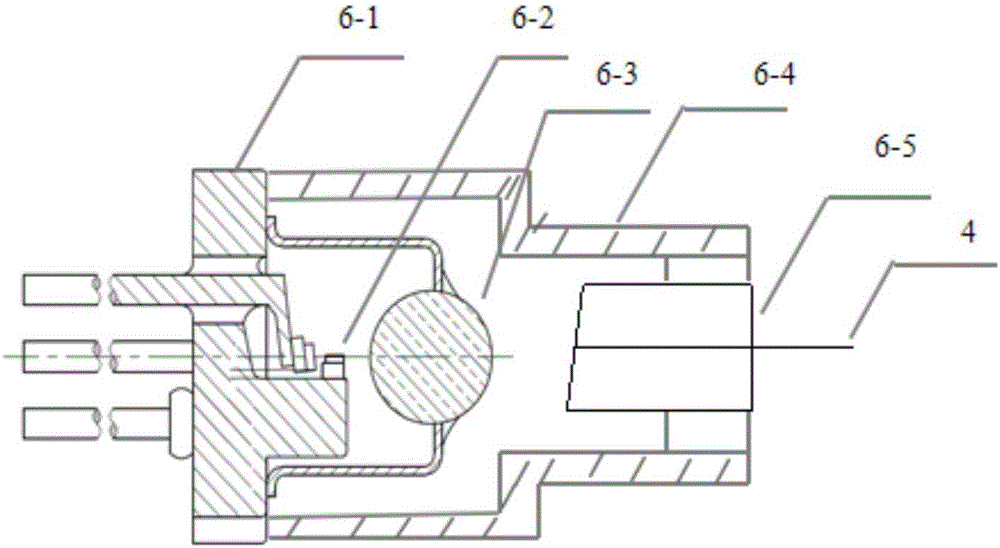

[0048] Embodiments of the present invention provide a structure of an optical transceiver module with a built-in silicon-based optoelectronic chip (SIP), which is a small pluggable structure (SFP), such as figure 2 As shown, it includes substrate 1, circuit board 2, SIP chip 3, optical fiber 4, LC optical interface 5, laser 6, spacer 8,

[0049] Substrate 1 carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com