Wide-base truck radial tire building machine belt drum and design method

A technology for radial tires and design methods, applied in the direction of design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as abnormal flow of rubber materials, improve the quality of finished tires, solve the problem of tread rubber deformation, and have Effects of Accuracy and Generalizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

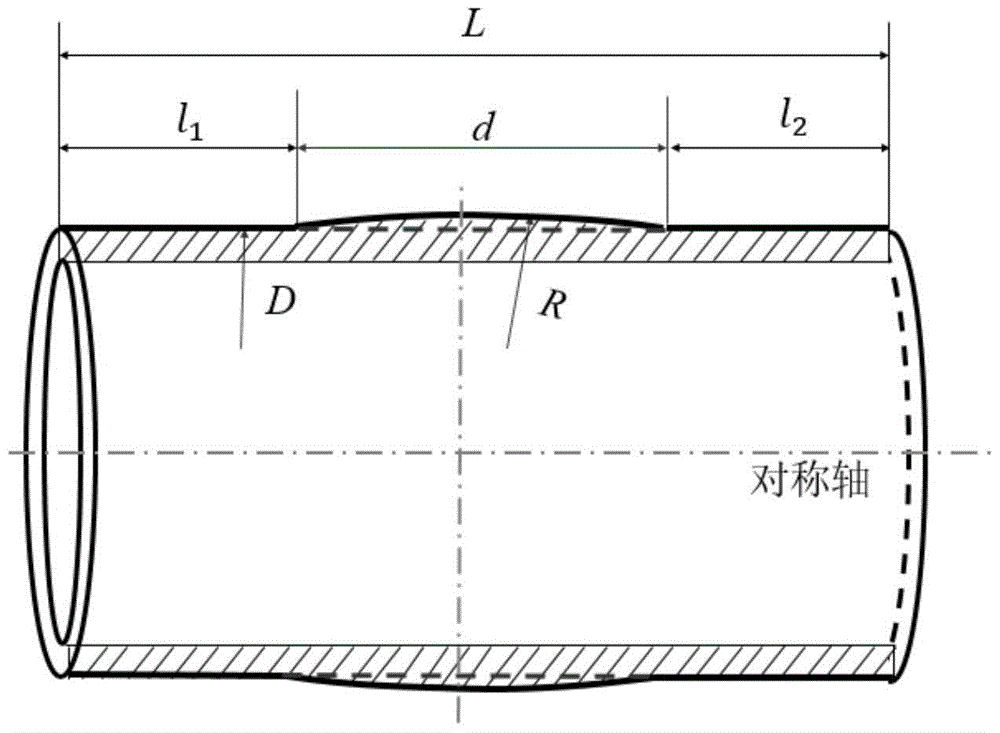

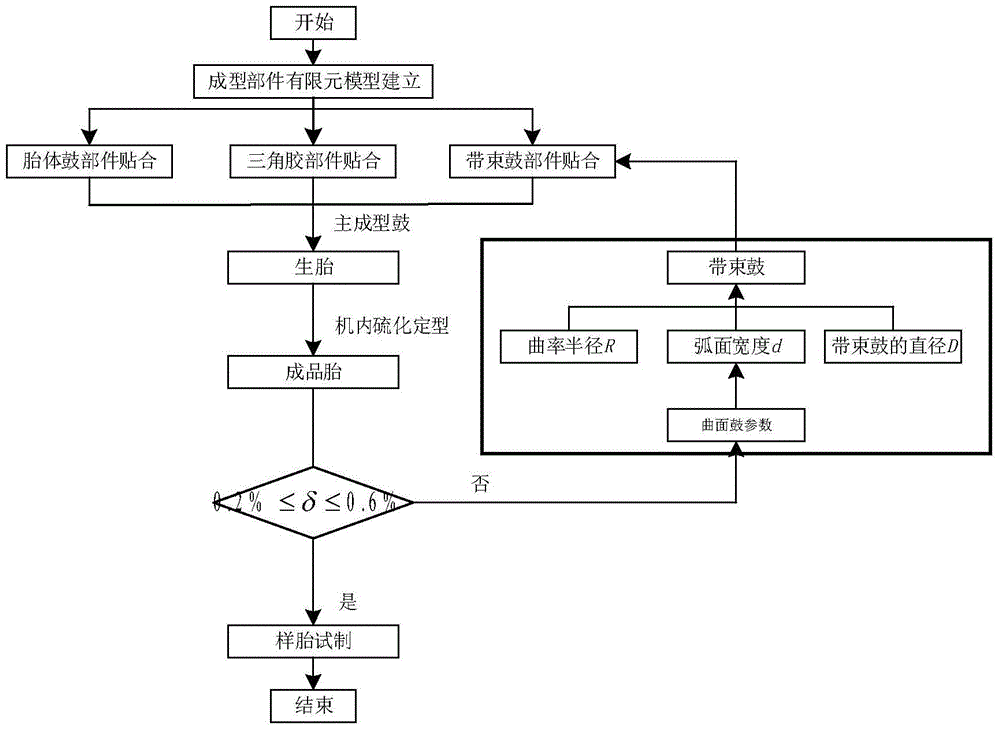

[0051] The design method of belt drum of wide base truck radial tire building machine described in the present invention, as figure 1 As shown, a protruding curved surface structure is designed in the middle section of the belt drum of the tire building machine, such as figure 1 shown. The cross-sectional contour line of the belt drum surface is composed of two straight segments and an arc segment between the two straight segments, and the width d of the arc segment is 80% of the width of the main belt layer in the theoretical material distribution diagram -120%; the radius of curvature R of the arc section is 70%-130% of the radius of curvature of the main belt layer; the diameter D of the belt drum, and the length l of the two straight sections 1 , l 2 for:

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com