An ultrasonic atomization ionization device

A technology of ultrasonic atomization and atomization chamber, which is applied to circuits, discharge tubes, electrical components, etc., can solve the problems of low efficiency, poor ionization effect of non-volatile liquid samples, etc., to expand the scope of application, simplify the sample processing process, enhance the The effect of the ionization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

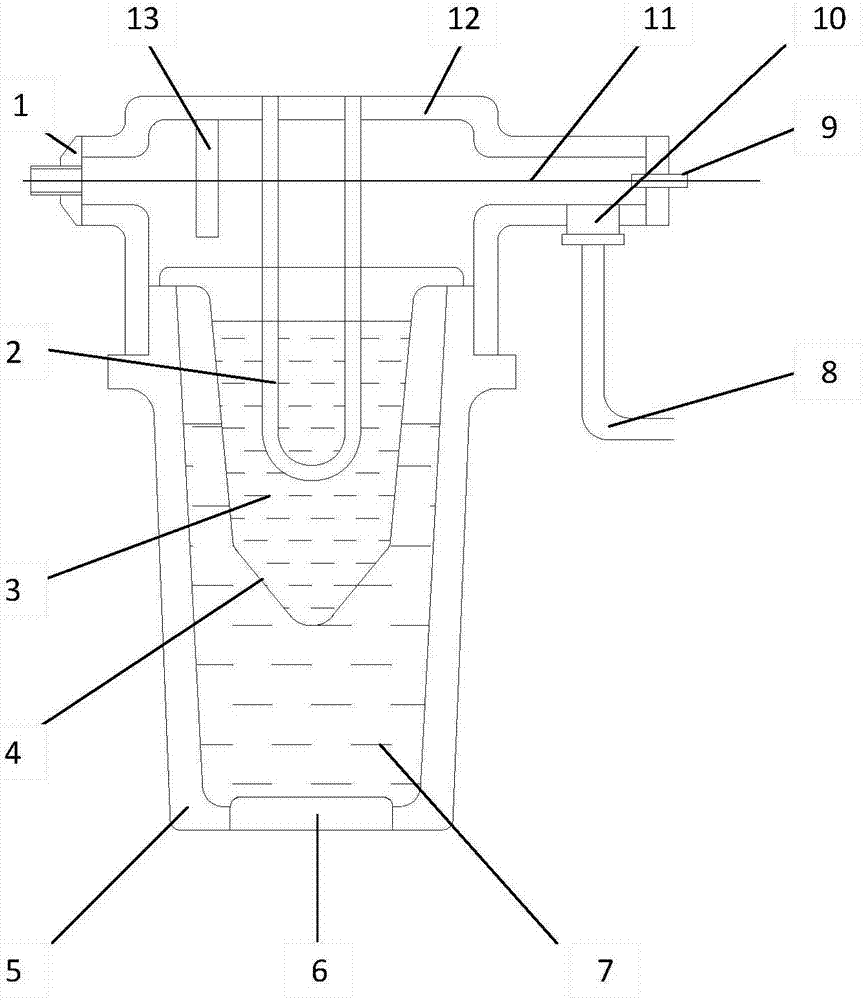

[0027] refer to figure 1 , in one embodiment, a kind of ultrasonic atomization ionization device, comprises atomization cavity, sample cup 4, atomization sheet 6, capillary 11, heating device 2 and carrier gas delivery tube 8, stored in the atomization cavity Liquid medium 7, the sample cup 4 is placed in the liquid medium 7 in the atomization chamber, the sample cup 4 stores the ionized liquid sample 3 to be atomized, and the heating device 2 is used to heat the sample cup The ionized liquid sample 3 to be atomized in 4; the ultrasonic vibration generated by the atomizing sheet 6 propagates through the liquid medium 7 to the ionized liquid sample 3 to be atomized in the sample cup 4, so as to realize the mist of the liquid sample The atomization cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com