Ionization method for analyzing sample, and dedicated ionization source

An ionization source and ionization technology are applied in the direction of material analysis using wave/particle radiation, analyzing materials, and parts of particle separator tubes. It can solve the problem that ionization equipment is not the most convenient, reduces the service life of electrodes, and is not Miniaturization of instruments and other issues to achieve the effect of reducing the discharge range, avoiding pollution, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

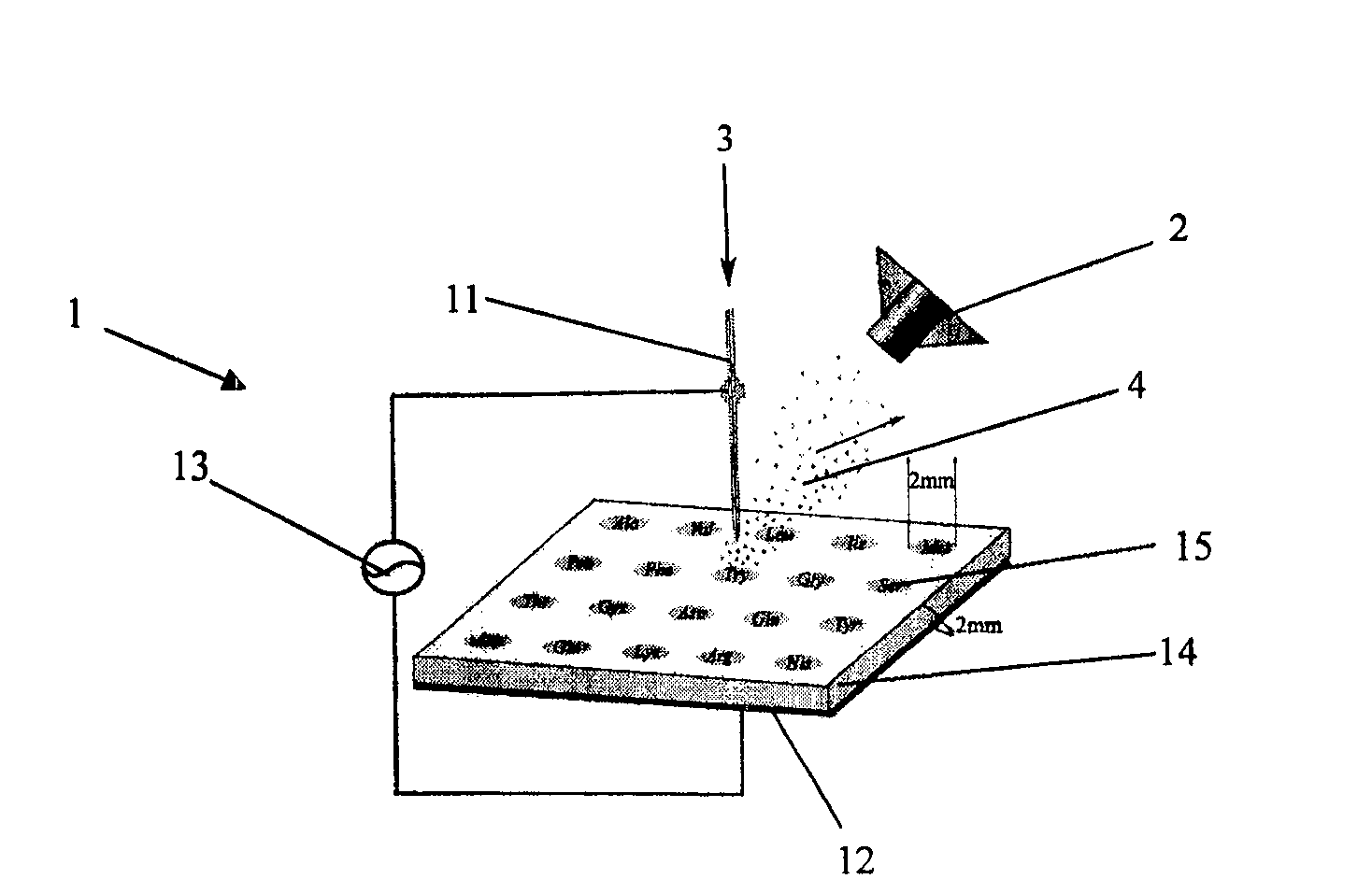

[0029] Such as figure 1 As shown, the ionization source 1 is composed of a hollow needle electrode 11 (inner diameter 0.1-0.5mm, about 50mm in length) and a copper plate 12 to form a counter electrode. The carrier gas 3 passes through the hollow needle electrode 11 at a flow rate of 20-200mL / min. The flow rate of gas 3 is measured by a gas flow meter, and the size can be adjusted by a needle valve. A flat insulating medium layer 13 (1-5 mm thick) is placed between the two counter electrodes, and for the convenience of operation, the insulating medium can be slightly in contact with the copper plate electrodes. Different samples are respectively arranged on the flat insulating medium, and the diameter of the sample point can be as small as the diameter of the needle tip; the distance between the hollow needle electrode 11 and the flat insulating medium layer 13 is about 5-15 mm. The power supply device is a 5-30W AC power supply, and the size of the device is small (6cm×4cm×3c...

Embodiment 2

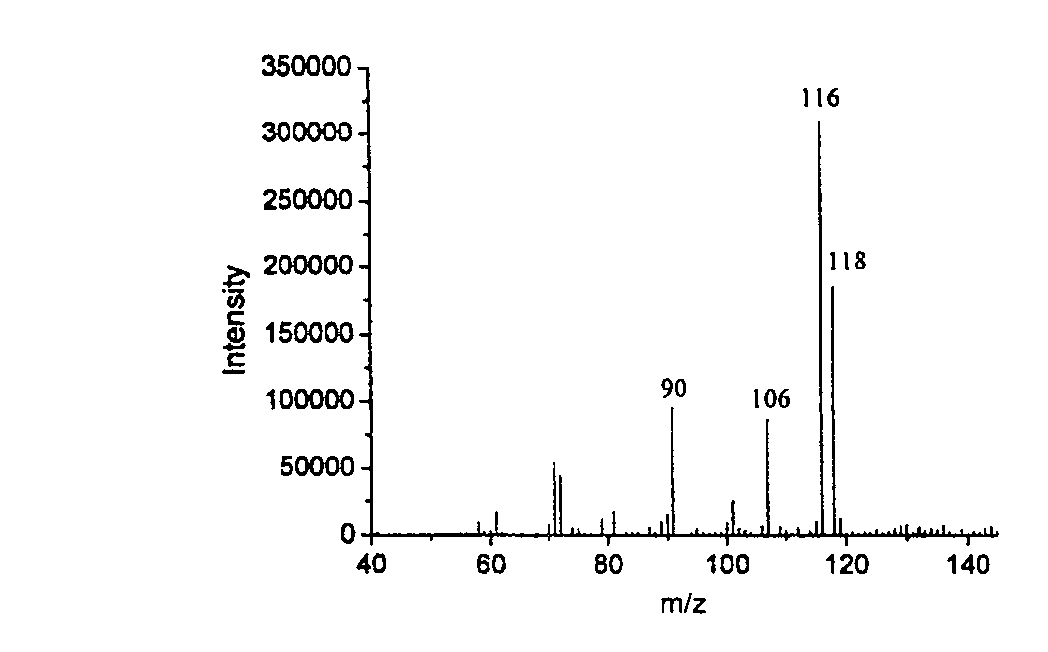

[0036] Ordinary glass (thickness 2mm) was selected as the insulating medium, and the glass was corroded with hydrofluoric acid before the experiment to obtain a rough surface. Take 3 μL of the mixed solution of four amino acids (L-valine, L-proline, L-serine and L-alanine) and spot on the insulating medium. Align the hollow needle electrode with this area, and the needle electrode is fed with helium at a flow rate of 50mL / min, and the discharge power is 30W, which are respectively connected to the two electrodes. When the power is turned on, discharge ionization starts. The ionization device is 40mm away from the sampling port of the mass spectrometer, so that the sample ions can be analyzed. Such as figure 2 , for the analysis of four amino acid mixed samples of L-valine (Mr=117), L-proline (Mr=115), L-serine (Mr=105) and L-alanine (Mr=89) mass spectrum. In the figure, the protonated molecular ion peaks of each amino acid can be clearly distinguished, indicating that the...

Embodiment 3

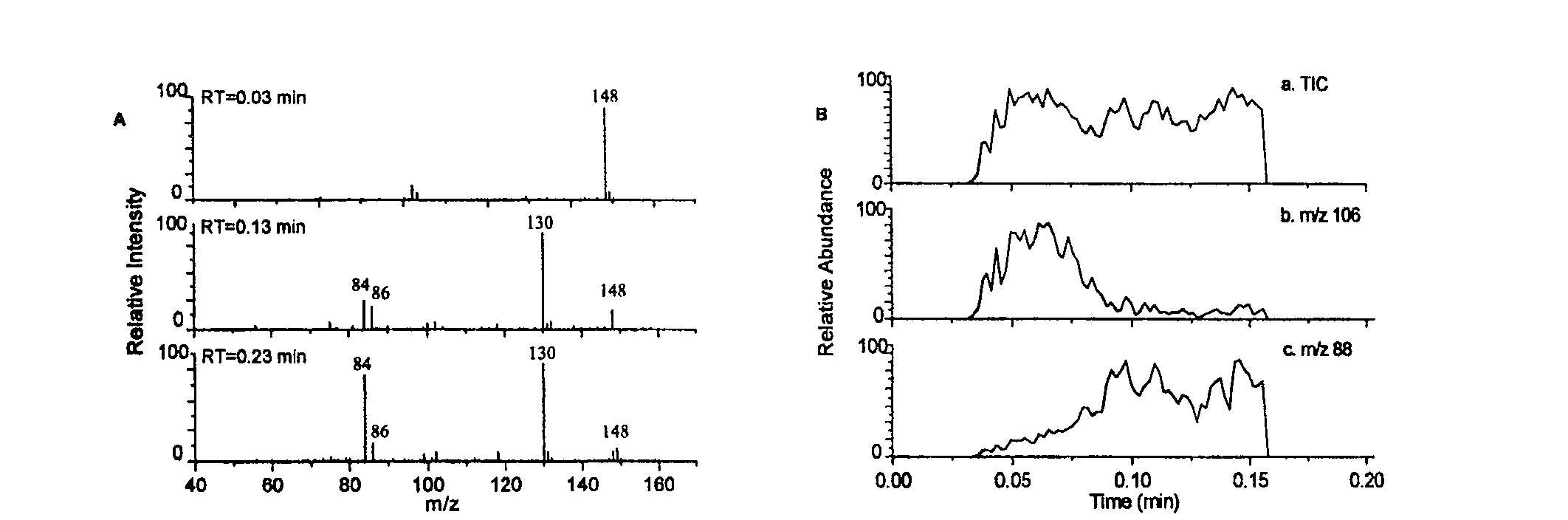

[0038] Taking amino acids as an example again, ionize L-glutamic acid (Mr 147) and L-serine (Mr 105). Ordinary glass (thickness 2mm) was selected as the insulating medium, and the glass was corroded with hydrofluoric acid before the experiment to obtain a rough surface. Taking amino acid as an example, take 3 μL of the sample solution and spot it on the insulating medium. Aim the hollow needle electrode at this area, and pass through the needle electrode with helium gas at a flow rate of 50mL / min; the power of the discharge power supply is 30W, connected to the two electrodes respectively, and the discharge ionization starts when the power is turned on. The ionization device is 40mm away from the sampling port of the mass spectrometer, so that the sample ions can be analyzed. Such as image 3 A, are the mass spectra of L-glutamic acid at different times; image 3 B, are the total ion chromatograms of different ions of L-serine and the ion chromatograms of fragment ions resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com