Polyurea or polyurethane capsules

A polyurethane and capsule technology, applied in and through a field, can solve the problems of low olfactory intensity, low stability, high toxicity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

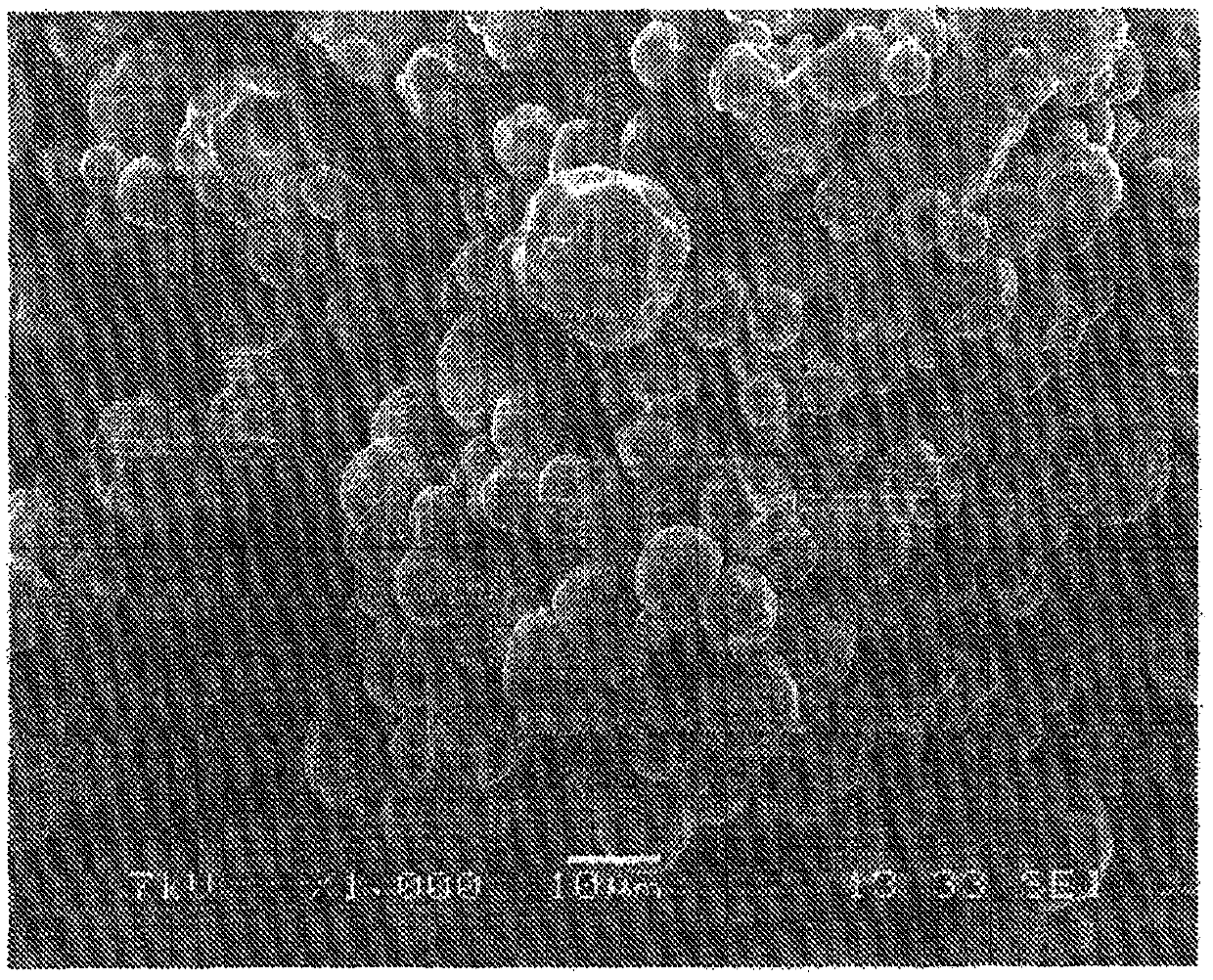

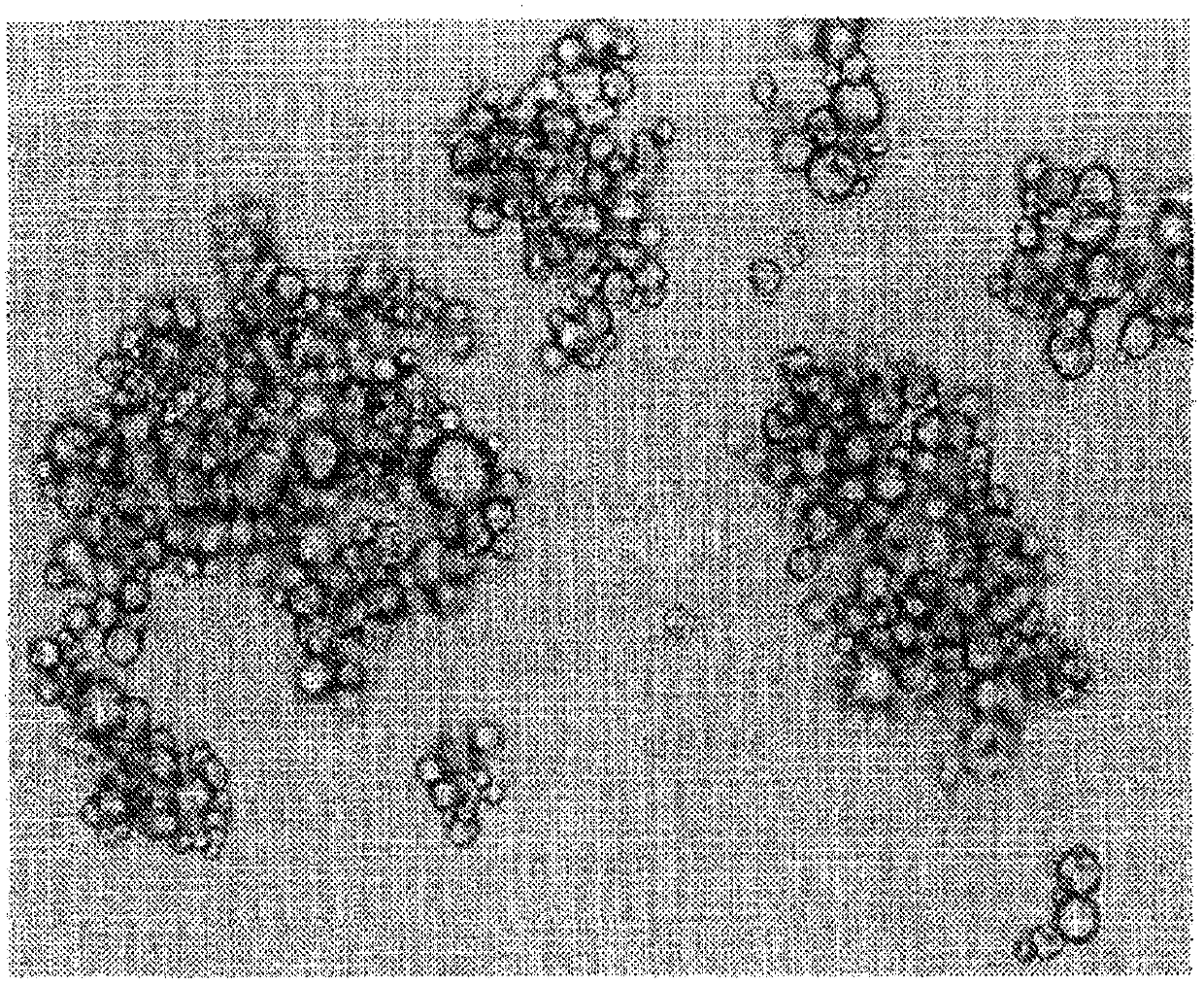

[0200] Example 1: Preparation of polyurea capsules with TAKENATE D-110N

[0201] Preparation of fragrance emulsion. Weigh 96 g of fragrance Greenfields (International Flavors and Fragrance, Union Beach, NJ) and mix it with 24 g of NEOBEE oil (Stepan, Chicago, IL) and 9.6 g of isocyanate monomer TAKENATE D-110N (Mitsui Chemicals Corporation, Rye Brook, NY) to form the oil phase. In a separate beaker, a 1.0% surfactant solution (160 grams) was prepared by dissolving a sufficient amount of FLEXAN II (Akzo Nobel, Bridgewater, NJ) in deionized (DI) water. The oil phase was then emulsified into the water phase by shearing (ULTRATURRAX, T25 Basic and IKA WERKE) at 6500 rpm for two minutes to form a perfume emulsion.

[0202] Formation of fragrance capsules. The fragrance emulsion was heated to 35°C in a round bottom vessel and 10.4 g of 56% tris(2-aminoethyl)amine (Sigma-Aldrich, St. Louis, MO). Capsule formation was immediately visible by light microscopy. The stirrer speed was ...

Embodiment 2

[0203] Example 2: Curing of Polyurea Capsules at High Temperature

[0204] Preparation of fragrance emulsion. Weigh 96 g of fragrance Greenfields (International Flavors and Fragrance, Union Beach, NJ) and mix it with 24 g of NEOBEE oil (Stepan, Chicago, IL) and 9.6 g of isocyanate monomer TAKENATE D-110N (Mitsui Chemicals Corporation, Rye Brook, NY) to form the oil phase. In a separate beaker, a 1.0% surfactant solution (160 grams) was prepared by dissolving sufficient FLEXAN II (Akzo Nobel, Bridgewater, NJ) in water. The oil phase was then emulsified into the water phase by shearing (ULTRA TURRAX, T25Basic and IKA WERKE) at 6500 rpm for two minutes to form a perfume emulsion.

[0205] Formation of fragrance capsules. The fragrance emulsion was heated to 35°C in a round bottom vessel and 10.4 g of 56% tris(2-aminoethyl)amine (Sigma-Aldrich, St. Louis, MO). Capsule formation was immediately visible by light microscopy. The stirrer speed was reduced after the addition of tri...

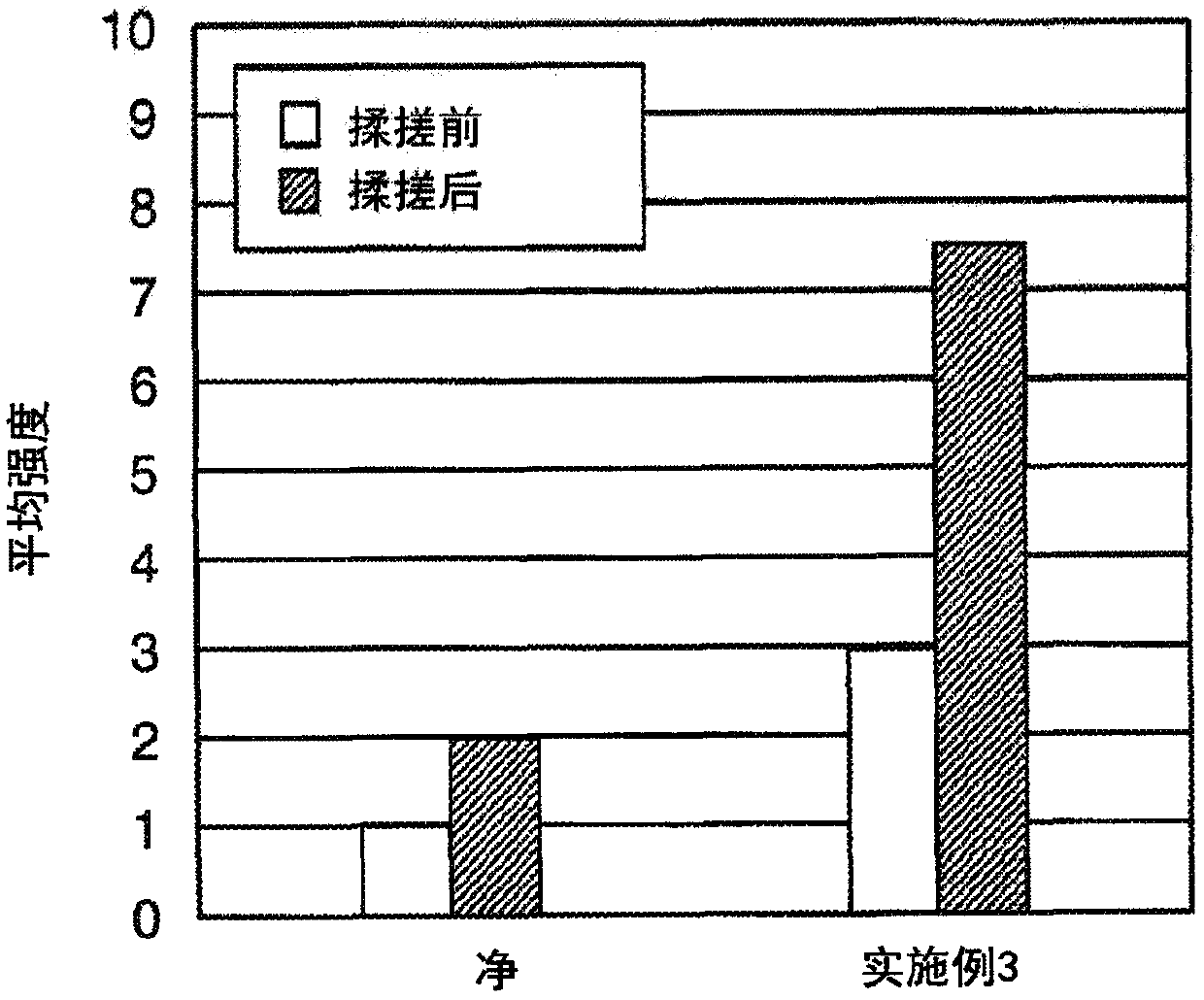

Embodiment 3

[0206] Example 3: Preparation of Polyurea Capsules with Dispersion Mixture

[0207] Preparation of fragrance emulsion. Weigh 96 g of fragrance Greenfields (International Flavors and Fragrance, Union Beach, NJ) and mix it with 24 g of NEOBEE oil (Stepan, Chicago, IL) and 9.6 g of isocyanate monomer TAKENATE D-110N (Mitsui Chemicals Corporation, Rye Brook, NY) to form the oil phase. In a separate beaker, a solution (130 g) containing 1.0% FLEXAN II (Akzo Nobel, Bridgewater, NJ) was mixed with 1% aqueous CMC (30 g) to form an aqueous phase. The oil phase was then emulsified into the water phase by shearing (ULTRATURRAX, T25 Basic, IKA WERKE) at 6500 rpm for two minutes to form a perfume emulsion.

[0208] Formation of fragrance capsules. The fragrance emulsion was heated to 35°C in a round bottom vessel and 10.4 g of 56% tris(2-aminoethyl)amine (Sigma-Aldrich, St. Louis, MO). Capsule formation was immediately visible by light microscopy. The stirrer speed was reduced after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com