Sugar cane derived extracts and methods of treatment

An extract, sugar cane technology, applied in the field of sugar cane-derived extract and treatment, can solve the problem of not considering the correlation and regulation of insulin response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

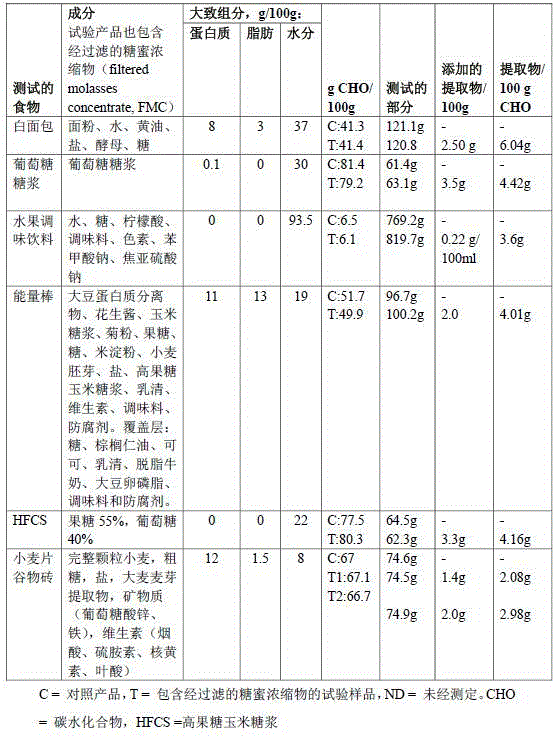

Examples

Embodiment

[0194] Preparation of polyphenol-rich molasses extract

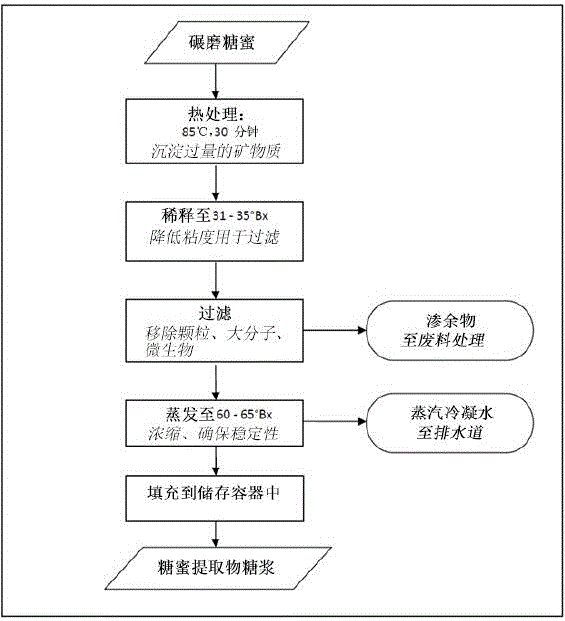

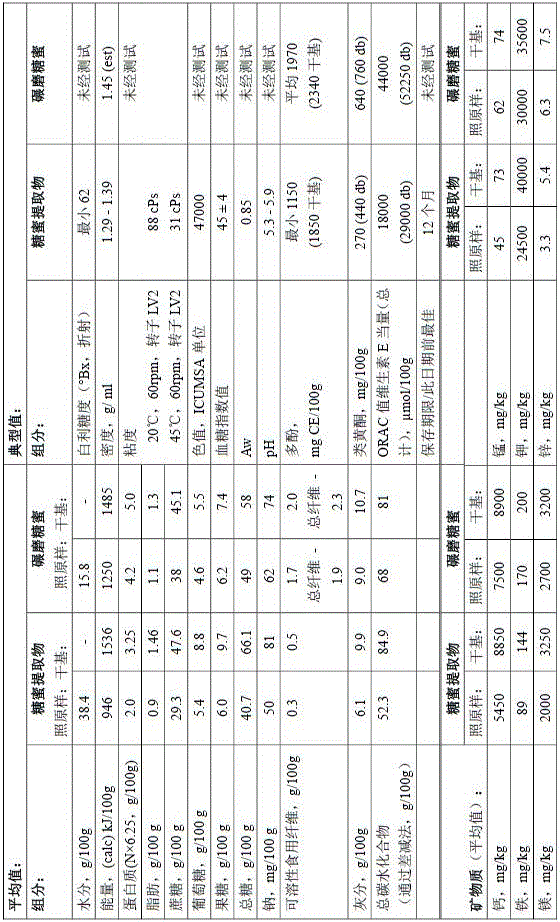

[0195] An extract was prepared comprising more concentrated, lower molecular weight, naturally occurring polyphenols (as defined herein) relative to the concentration of each of those polyphenols present in cane molasses. For the preparation of the extract of this embodiment of the invention, the raw material is milled molasses obtained from a sugar factory that produces raw sugar from sugar cane and is HACCP certified. exist figure 1 The process shown in , involves heat treatment of molasses at 85°C for a minimum of 30 minutes to precipitate calcium added during sugarcane juice processing in primary mills. The molasses was diluted with water to 31-35° Brix to reduce viscosity prior to filtration (GEA Engineering Pty Ltd, Blackburn, Victoria, Australia) which removed suspended solids and other large Components, including microorganisms.

[0196] The permeate is passed directly to the evaporator feed tank and concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com