Fiber coatings with low young's modulus and high tear strength

A weight, compound technology, applied in coatings, glass fibers, clad fibers, etc., can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

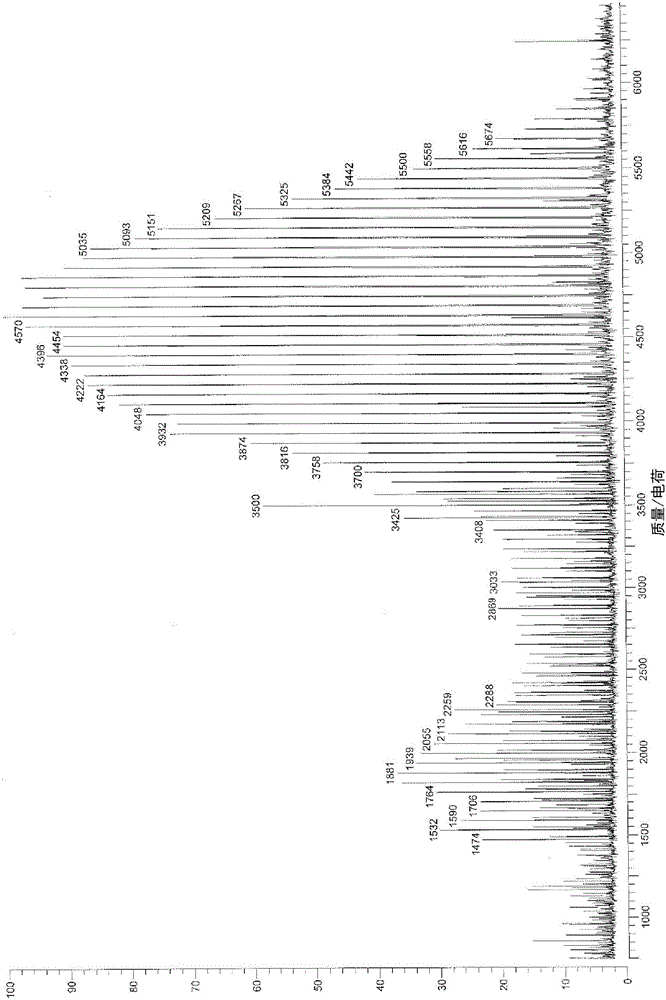

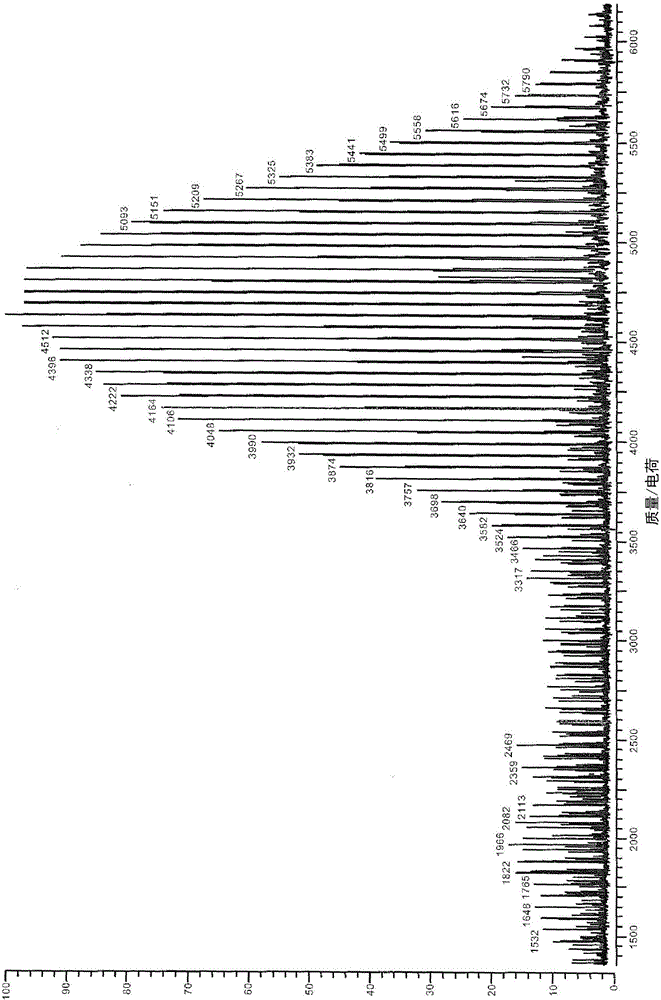

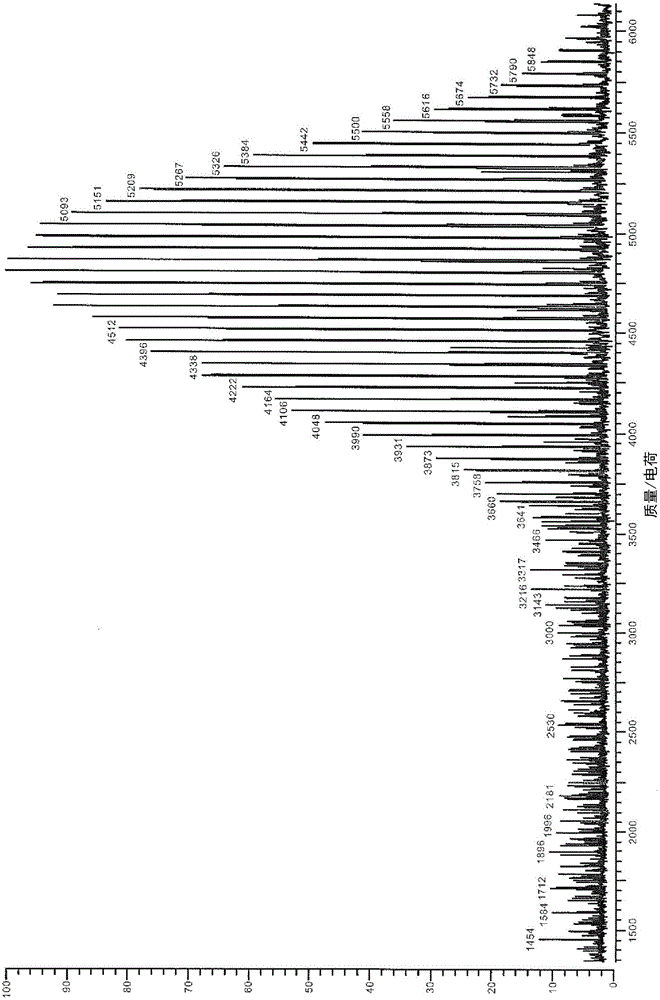

[0199] Several coatings formed from the coating composition containing the oligomeric material of the present invention were tested. These tests include measurements of Young's modulus and tear strength. In the following, the components, processing conditions, test methods and test results of the coating composition are described.

[0200] According to the exemplary reaction described above, H12MDI (4,4'-methylene bis(cyclohexyl isocyanate)), PPG4000 (M n An exemplary oligomeric material was prepared at about 4000 g / mol of polypropylene glycol) and HEA (-2-hydroxyethyl acrylate). All reagents use the original reagents provided by the manufacturer, without any further purification. H12MDI is obtained from Aldrich or Bayer. Three variants of PPG4000 were used in the synthesis of sample oligomers. Variant 1 (Voranol 220-028 available from Dow Chemical) contains a greater amount of low molecular weight material. Variation 2 (polyethylene glycol P4000 available from Dow Chemical) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com