Gravure printing technology of paper packaging box and printing equipment

A gravure printing process and printing equipment technology, applied in printing, printing machines, printing post-processing, etc., can solve the problem of large solvent residues in packaging boxes, and achieve the effects of saving usage and preventing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

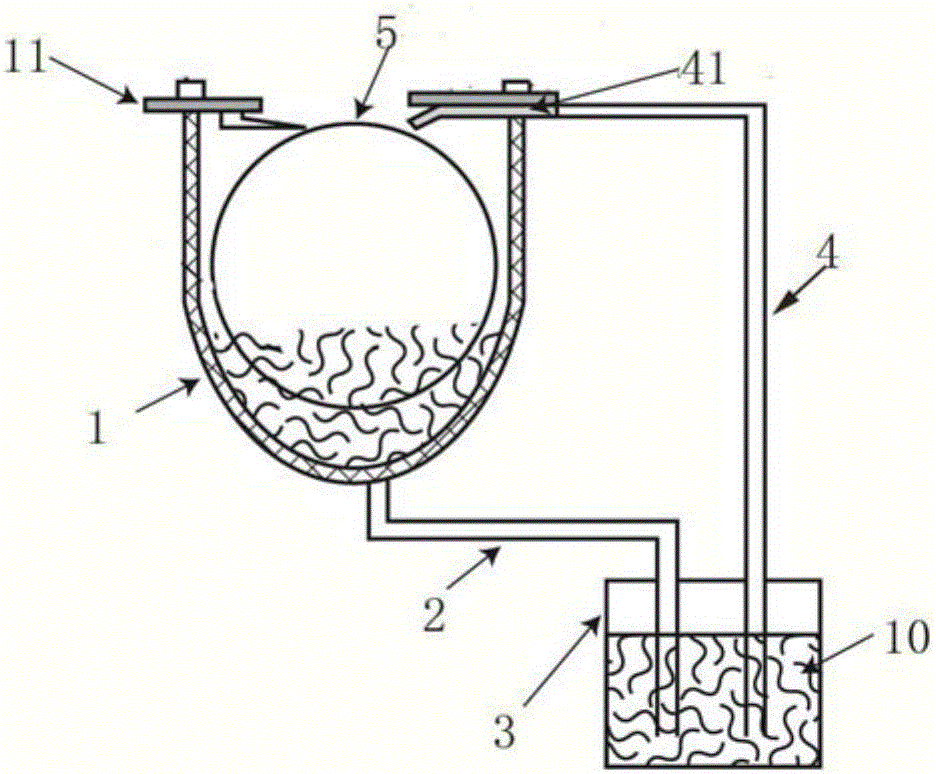

[0027] The printing equipment includes a closed sleeve 11, a plate cylinder 5, an ink tank 1, an ink return conduit 2, an ink tank 3 and an ink supply conduit 4, the plate cylinder 5 is placed in the ink tank 1, the ink tank 1, the ink return The conduit 2, the ink tank 3, the ink delivery conduit 4, and the upper ink tank 1 are connected in sequence, so that the ink 10 forms a circulation in the upper ink tank 1 and the ink tank 3. The ink conduit 4 sprays down from the top of the printing plate cylinder 5 and returns to the upper ink tank 1. The closed cover 11 includes two left and right baffles and is respectively connected to the top of the upper ink tank 1, so that the ink 10 can be prevented from flowing out of the ink supply conduit. The nozzle 41 of 4 sprays down and falls on the plate cylinder 5 and splashes out, and the bottom surface of the upper ink tank 1 is a concave arc surface in the present embodiment simultaneously. Of course, the printing equipment in this ...

Embodiment 2

[0029] Paper: 225g / m 2 white cardboard;

[0030] Alcohol-soluble ink is the following substances by weight: nitrocellulose 35%, pigment 15%, ethanol 40%, ethyl acetate 5%, acetyl tributyl citrate 1%, auxiliary agent 4%;

[0031] Dilute the ink: the dilution solvent is ethanol and ethyl acetate with a mixing ratio of 8:2 (volume ratio), and the viscosity of the diluted alcohol-soluble ink is controlled to 16 seconds;

[0032] Production of the printing plate cylinder: the electronic engraving process is used to produce the printing plate cylinder, the screen line number is 80 lines / cm, the screen line angle is 38°, the electronic engraving method is adopted, and the cell depth is 45 μm;

[0033] Printing: web gravure printing is used to print patterns and characters. During the printing process, the printing equipment in Example 1 is used to continuously supply ink to the gravure cylinder.

[0034] Drying: After printing, the ink layer on the surface of the substrate is dried...

Embodiment 3

[0037] Paper: 90g / m 2 coated paper;

[0038] Alcohol-soluble ink is the following weight ratio: cyclohexanone-formaldehyde polymer resin 50%, pigment 5%, ethanol 30%, ethyl acetate 10%, acetyl tributyl citrate 4%, printing ink additive 1%;

[0039] Dilute the ink: the dilution solvent is ethanol and ethyl acetate with a mixing ratio of 7:3 (volume ratio), and the viscosity of the diluted alcohol-soluble ink is controlled at 14 seconds;

[0040] Production of the printing plate cylinder: the electronic engraving process is used to produce the printing plate cylinder, the number of screen lines is 80 lines / cm, the angle of the screen line is 38°, and the depth of the engraving cell is 55 μm by the electronic engraving method;

[0041] Printing: web gravure printing is used to print patterns and characters. During the printing process, the printing equipment in Example 1 is used to continuously supply ink to the gravure cylinder.

[0042] Drying: After printing, the ink layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com