Highly conductive flexible self-supported graphene film and preparation method thereof

A graphene film, self-supporting technology, applied in the direction of carbon-silicon compound conductors, etc., can solve the problems of low material utilization, unfavorable batch production, and large quantities, and achieve high raw material utilization, convenient operation, and simple process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of a highly conductive flexible self-supporting paper-like graphene film, comprising the steps of:

[0023] (1) According to the improved Hummers method, using graphite as a raw material, preparing a graphene oxide aqueous solution with a concentration of 0.2 to 3 mg / ml;

[0024] (2) The solid substrate is first subjected to plasma surface treatment, and the graphene oxide solution is titrated on the treated solid substrate, and further vacuum-dried at 50-100 degrees Celsius for 2-6 hours to obtain a graphene oxide film;

[0025] (3) Putting the graphene oxide film on the solid substrate into the aqueous solution of hydroiodic acid with a concentration of 47-80wt.%, and then reacting in an oil bath at 50-200 degrees Celsius under airtight conditions for 1-5 hours to obtain a suspension in Free-standing graphene films on the surface of aqueous hydroiodic acid solution. The mass ratio of hydroiodic acid to graphite oxide film is 5-30:1.

[0026] (4)...

Embodiment 1

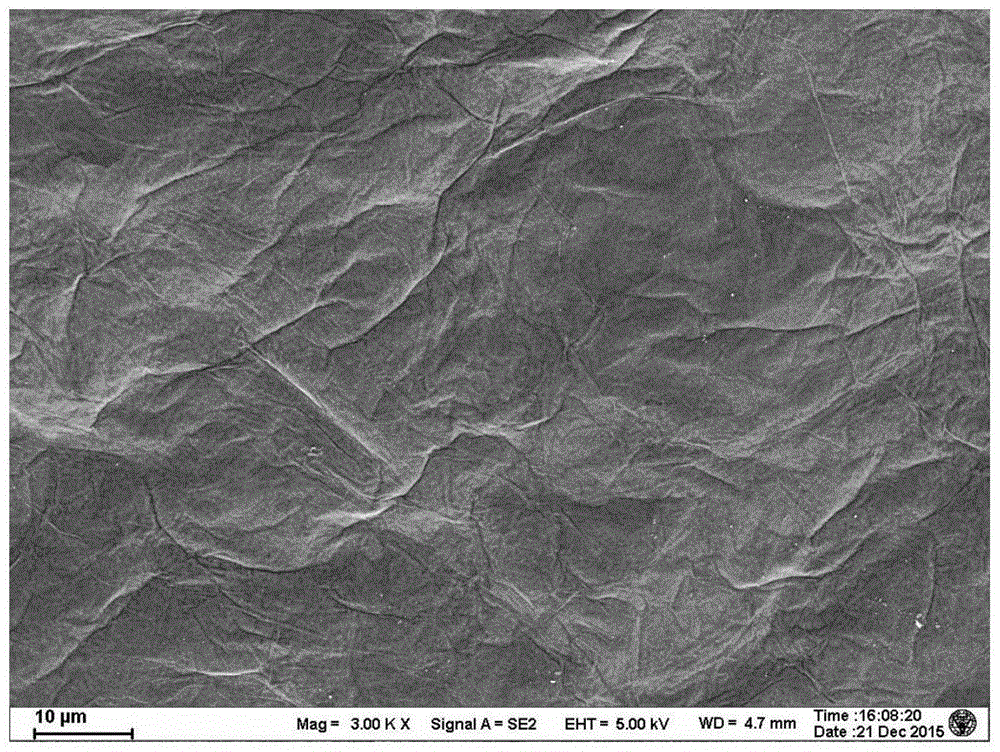

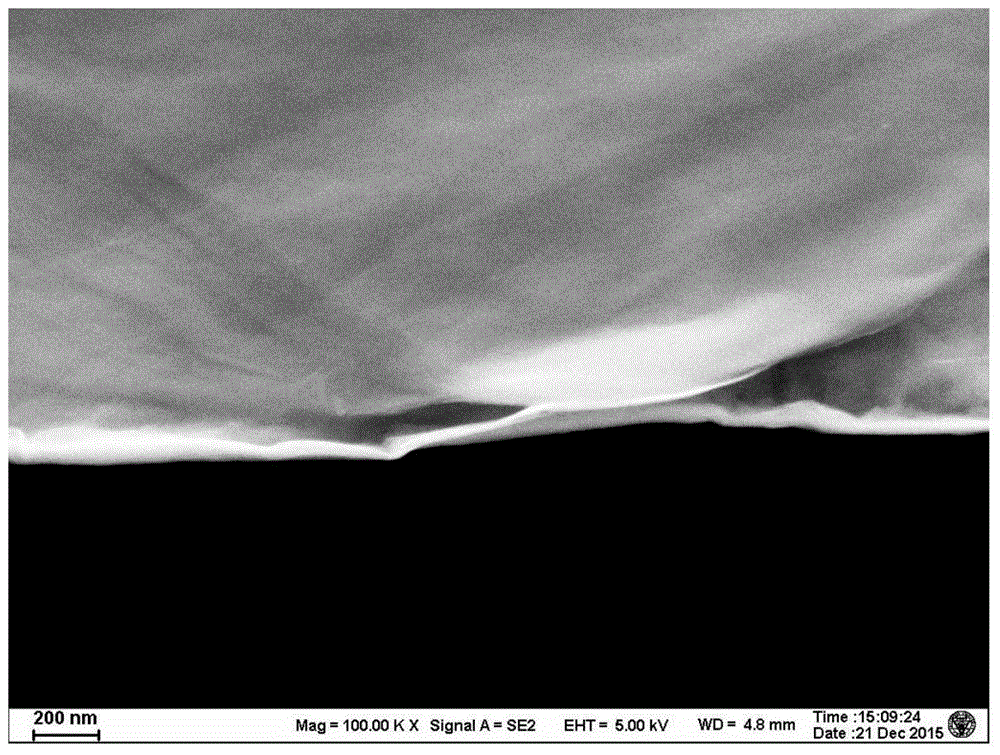

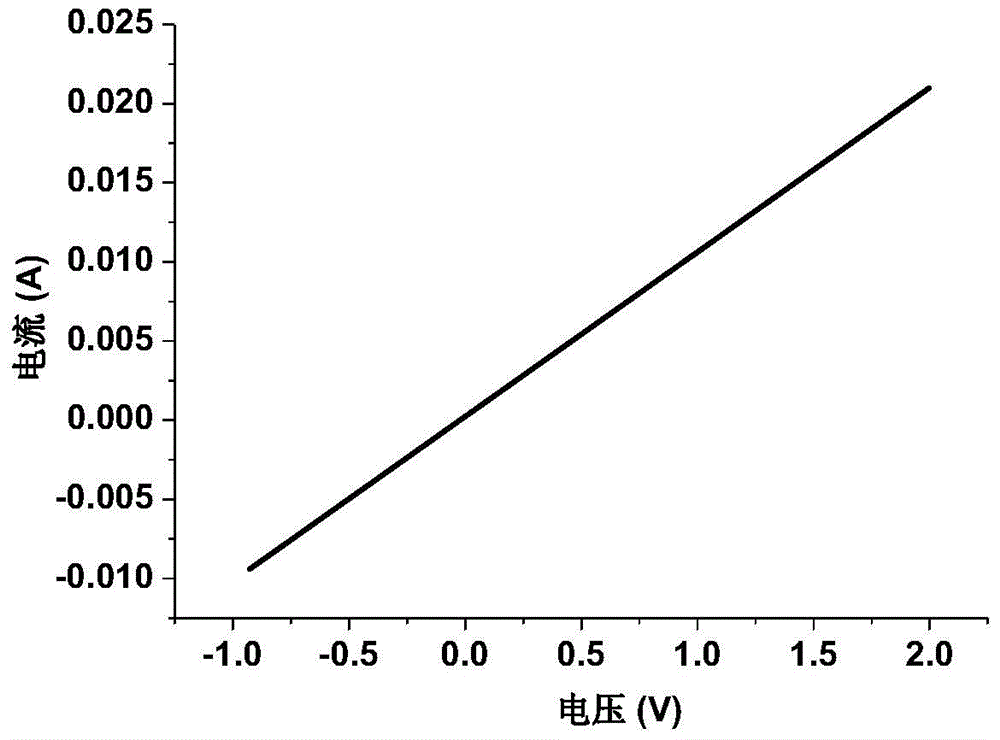

[0027] Embodiment 1: the preparation of highly conductive flexible self-supporting graphene film

[0028] (1) according to the improved Hummers method (document ACSNano4 (8): 4806 (2010), Improvedsynthesisofgrapheneoxide), with graphite as raw material, the graphene oxide aqueous solution that preparation concentration is 1.5mg / ml;

[0029] (2) The glass substrate is subjected to plasma surface treatment, and the graphene oxide aqueous solution is evenly titrated on the glass substrate, and further vacuum-dried at 65 degrees Celsius for 3 hours to obtain a graphene oxide film;

[0030] (3) Putting the graphene oxide film on the glass substrate into a concentration of 55wt.% hydroiodic acid aqueous solution, reacting in an oil bath at 100 degrees Celsius under airtight conditions for 2h, to obtain the self- Supported graphene film. The mass ratio of hydroiodic acid to graphite oxide film is 5:1.

[0031] (4) Transfer the self-supporting graphene film to pure water for immersi...

Embodiment 2

[0032] Example 2: Preparation of highly conductive flexible self-supporting graphene film

[0033] (1) according to the improved Hummers method, taking graphite as raw material, the graphene oxide aqueous solution that preparation concentration is 0.5mg / ml;

[0034] (2) The glass substrate is subjected to plasma surface treatment, and the graphene oxide aqueous solution is evenly titrated on the glass substrate, and further vacuum-dried at 100 degrees Celsius for 2 hours to obtain a graphene oxide film;

[0035] (3) Putting the graphene oxide film on the glass substrate into a concentration of 80wt.% hydroiodic acid aqueous solution, reacted for 5h in an oil bath at 50 degrees centigrade under airtight conditions, and obtained the self- Supported graphene film. The mass ratio of hydroiodic acid to graphite oxide film is 15:1.

[0036] (4) Transfer the self-supporting graphene film to pure water for immersion, rinse, and dry at room temperature to obtain a highly conductive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com