Long-afterglow luminescent material and preparation method thereof

A technology of long afterglow luminescence and carbon monoxide, which is applied in the direction of luminescent materials, chemical instruments and methods, and can solve the problem of lack of long afterglow luminescent materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of the above-mentioned long-lasting luminescent material, comprising: S1) mixing Ln source compound, Re source compound, Al source compound and Ga source compound, and performing one-time roasting under a protective atmosphere to obtain the primary product: S2) The primary product is subjected to secondary firing under a protective atmosphere to obtain a long-lasting luminescent material; wherein, Ln is two of Gd, Y, Lu and La; Re is Tb, Eu, Ce, Nd, Er, One or more of Yb and Bi; the molar ratio of the Ln element in the Ln source compound, the Re element in the Re source compound, the Al element in the Al source compound to the Ga element in the Ga source compound is [(2-x) ×a]: (x×a): [(1-y)×b×2]: (y×b×2); 2≤a≤4, 3≤b≤8, 0.0001≤x≤0.5, 0.31≤ y≤0.99.

[0044] Wherein, the Ln, Re, a, b, x, and y are the same as those described above, and will not be repeated here.

[0045] The Ln source compound is a compound contai...

Embodiment 1

[0058] take Y 2 o 3 (99.9%), Gd 2 o 3 (99.9%), Al 2 o 3 (analytical pure), Ga 2 o 3 (analytical pure), CeO 2 (99.99%) were mixed according to the molar ratio of 1.5:1.461:2:3:0.078, fully ground to obtain a mixture.

[0059] Put the mixture into a corundum crucible, put the above-mentioned corundum crucible with the mixture into a high-temperature furnace, and bake it at 1550°C for 5 hours in the presence of nitrogen, cool it down to room temperature naturally, take it out, crush it and grind it evenly to obtain a powder Primary product: Put the primary product into a corundum crucible, then place it in a high-temperature furnace, and roast it at 900°C for 4 hours in the presence of hydrogen, cool it down to room temperature naturally, take it out, crush it and grind it evenly, and it is the long-lasting luminescent material 3[YGd 0.974 o 3 0.026Ce] 5[0.4Al 2 o 3 0.6Ga 2 o 3 ].

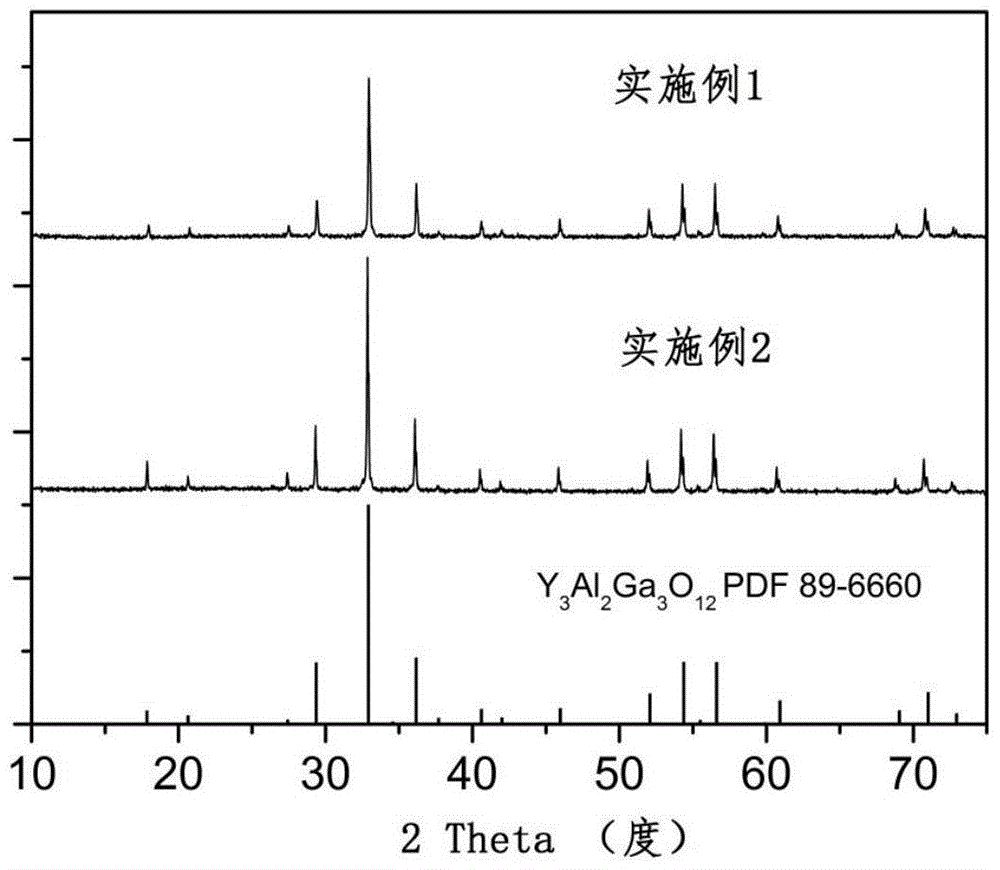

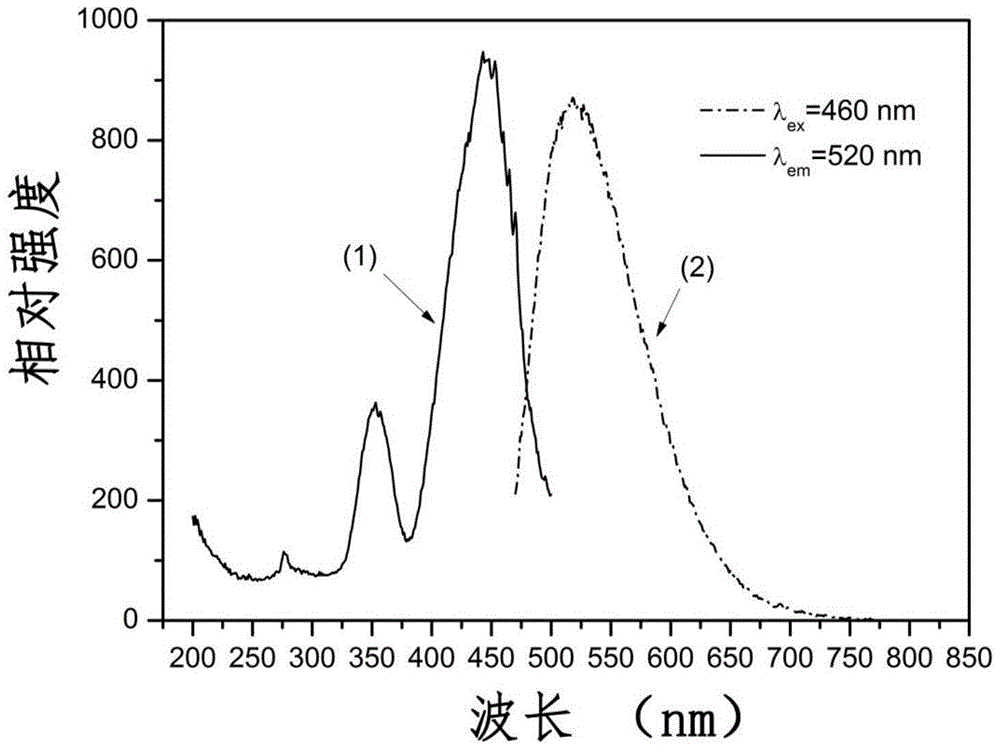

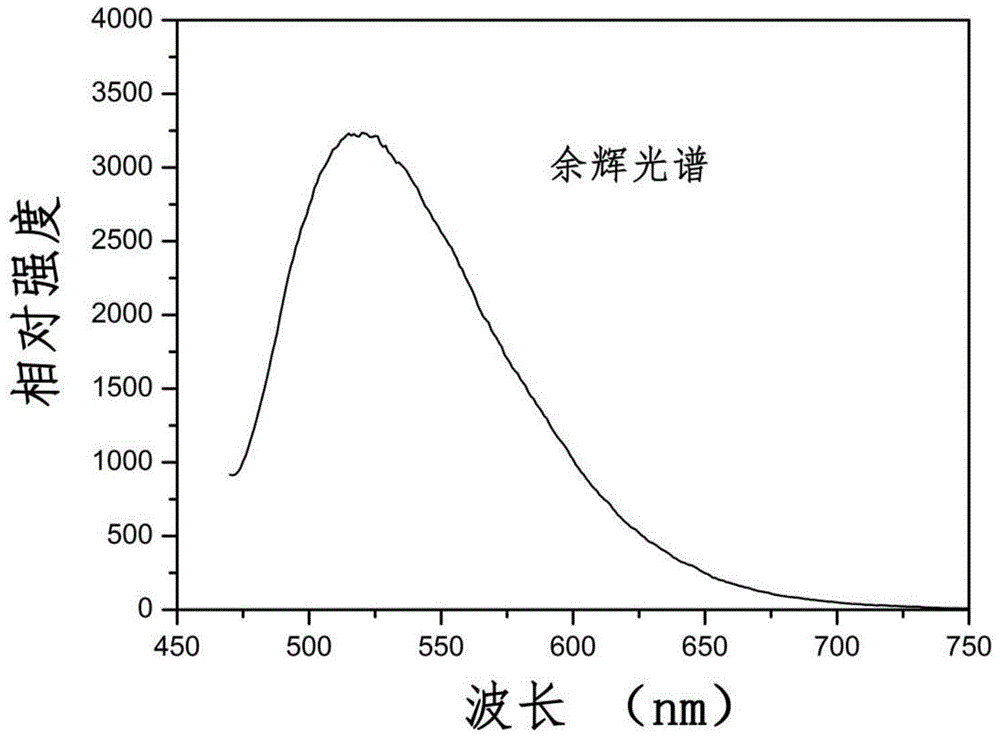

[0060] Carry out X-ray diffraction analysis to the long afterglow luminescent materi...

Embodiment 2

[0063] take Y 2 o 3 (99.9%), Lu 2 o 3 (99.9%), Al 2 o 3 (analytical pure), Ga 2 o 3 (analytical pure), CeO 2 (99.99%) were mixed according to the molar ratio of 1.5:1.461:2:3:0.078, fully ground to obtain a mixture.

[0064] Put the mixture into a corundum crucible, put the above-mentioned corundum crucible with the mixture into a high-temperature furnace, and bake it at 1550°C for 5 hours in the presence of nitrogen, cool it down to room temperature naturally, take it out, crush it and grind it evenly to obtain a powder The initial product: Put the initial product into a corundum crucible, then place it in a high-temperature furnace, and roast it at 900°C for 4 hours in the presence of hydrogen, cool it down to room temperature naturally, take it out, crush it and grind it evenly, and it is the long-lasting luminescent material 3[YLu 0.974 o 3 0.026Ce] 5[0.4Al 2 o 3 0.6Ga 2 o 3 ].

[0065] X-ray diffraction analysis was performed on the long-lasting luminescent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com