Process and composition for treating metal surfaces using trivalent chromium compounds

A technology of metal surface and composition, applied in metal material coating process, coating, primer, etc., can solve problems such as environmental hazards and health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The 1900 pretreatment is a pretreatment composition sold by Bulk Chemicals, Incorporated of Reading, PA that includes distilled water, aminopropyltriethoxysilane, and fluozirconic acid. More specifically, 1900 pretreatment agents include distilled water, A-1100 / DyslanAmeopure, hydrofluorozirconic acid, and ErosinRedGR. A-1100 / Dyslan Ameopure is aminopropyltriethoxysilane commercially available from Sivento Incorporated of Piscataway, New Jersey, and ErosinRedGR is a dye commercially available from Pylam Products of Tempe, Arizona. The weight percentages added are as follows: 85.1899% of distilled water, 9.57% of A-1100 / DyslanAmeopure, 5.24% of hydrofluorozirconic acid (concentration 45%), and 0.0001% of ErosinRedGR.

[0048] High-strength aluminum alloy 2024-T3 and 6061-T6 panels were used for composition testing. Bulk 737G cleaner is a proprietary alkaline powder cleaner sold by Bulk Chemicals, Incorporated of Reading, PA and was used as the cleaner.

[0049] P...

Embodiment 2

[0058] 2024-T3 and 6061-T6 boards in Bulk Cleaning was performed by immersing in 737G detergent for 2 minutes at 140°F with a detergent content of 15 grams per liter. The plates were then rinsed with tap water for 1 minute at ambient conditions. Plates were then rinsed with deionized water for 1 minute at ambient conditions.

[0059] The pretreatment composition includes 2% v / v of 1900 pretreatment agent+0.42 g / L chromium(III) fluoride tetrahydrate+0.005 g / L ammonium bifluoride+0.66 g / L 45% fluozirconic acid, adjust pH to about 4. The panels were then dipped again in the above pretreatment composition for 2, 5 or 10 minutes at 110°F.

[0060] The plate was then dried with a hot air drier. The 2024-T3 panels were salt sprayed for 336 hours as detailed in ASTM B117-07 above. The 2 minute preconditioning failed. 5 min and 10 min preconditioning passes. The 10 minute pretreated had small black spots, but no pitting or white corrosion.

[0061] As discussed above, accepta...

Embodiment 3

[0066] Various 2024-T3 and 6061-T6 boards in Bulk Cleaning was performed by immersing in 737G detergent for 2 minutes at 140°F with a detergent content of 15 grams per liter. The plates were then rinsed with tap water for 1 minute at ambient conditions. Plates were then rinsed with deionized water for 1 minute at ambient conditions.

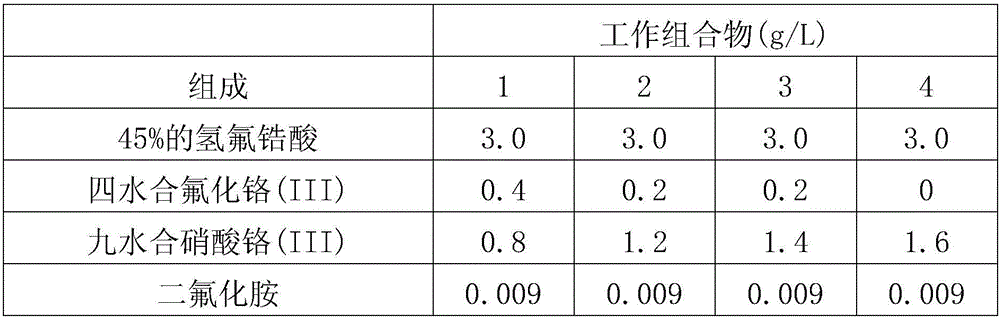

[0067] The pretreatment composition included 3.5% v / v of 1900 pretreatment agent+0.37 g / L chromium (III) fluoride tetrahydrate+0.82 g / L chromium nitrate nonahydrate (III)+0.009 g / L ammonium difluoride+1.16 g / L 45% fluozirconic acid, Adjust the pH to about 4.

[0068] The panels were then dipped in the above pretreatment composition for 10 minutes at 95-100°F. The plate was then dried with a hot air drier. 2024-T3 and 6061-T6 panels were salt sprayed as detailed in ASTM B117-07 above. The 2024-T3 board passed the 336-hour test, and the 6061-T6 board passed the 168-hour test.

[0069] As discussed above, with the Keithley Multimeter mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com