Cylinder block moving type single-action low-noise energy-saving impact cylinder

A technology for impacting cylinders and cylinder body movement, applied in the field of impacting cylinders, can solve the problems of high impact noise, poor controllability and accuracy, high manufacturing costs, etc., to reduce impact noise, improve controllability and accuracy, and save energy. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

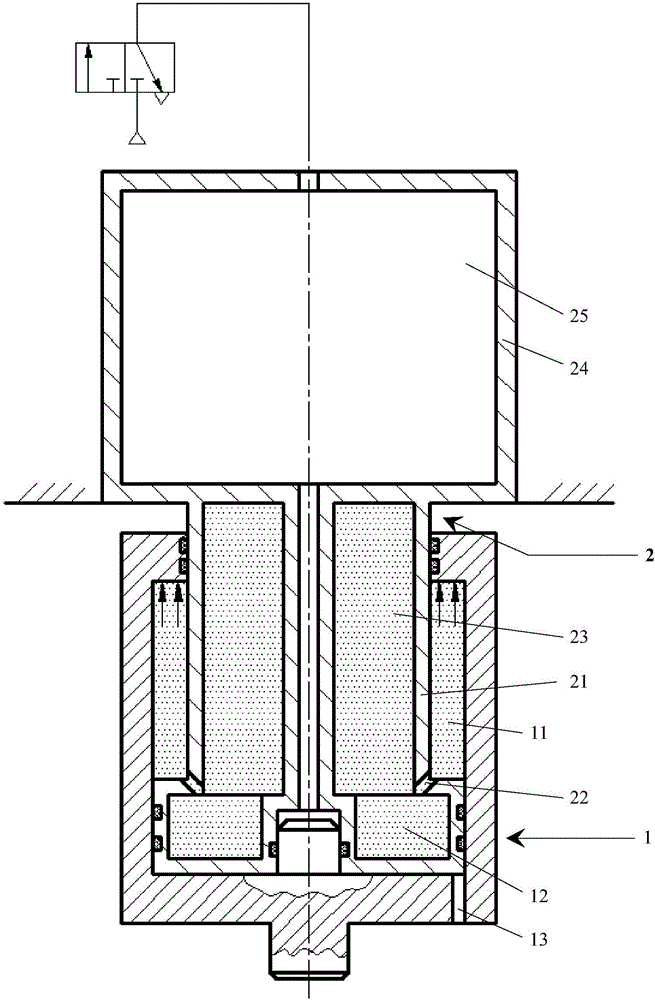

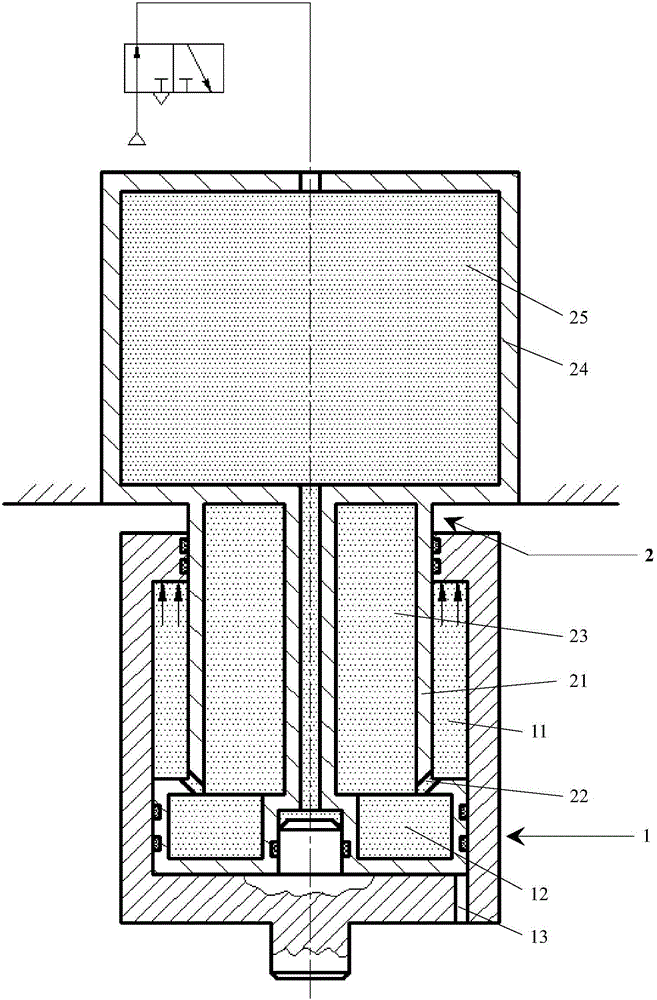

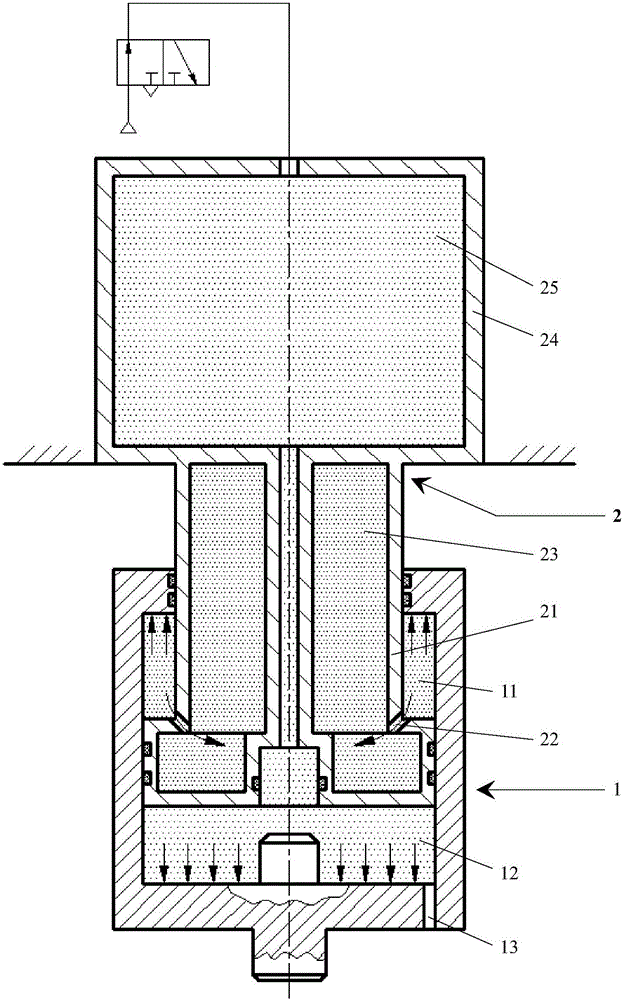

[0018] The accompanying drawing is a specific embodiment of a single-acting, low-noise, energy-saving impact cylinder for a cylinder block for a press of the present invention. Different from the existing general impact cylinder, the present invention adopts the movement mode of the cylinder assembly 1, and the piston-piston rod assembly 21 is relatively fixed, and the fixed part also includes an accumulator cylinder fixedly connected to the piston-piston rod assembly 21 Component 24.

[0019] It can be seen from the figure that the piston-piston rod assembly 21 surrounds the rod inner cavity 22, and the piston-piston rod assembly 21 and the cylinder assembly 1 naturally form the rod outer cavity 11; on the piston-piston rod assembly 21, air is processed The circulation hole 22 enables the rod inner cavity 22 and the rod outer cavity 11 to communicate with each other to form an air volume in the cylinder; the air volume in the cylinder is filled with and holds compressed gas for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com