A vacuum pump tail gas anti-static, fireproof, explosion-proof conveying device

A conveying device, anti-static technology, applied in explosion-proof conveying device, vacuum pump tail gas anti-static, fire protection field, can solve the problem of static inflammability and explosion, and achieve the effect of reducing the content of organic solvent and good support and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

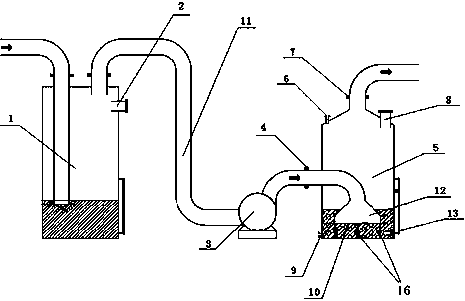

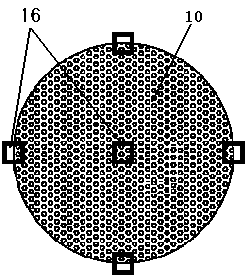

[0023] Embodiment 1, the present invention includes a water-sealed tank 1, an explosion-proof fan 3, and a water-washing tank 5. A first burst disc 2 is provided on the upper right side of the water-sealed tank 1, and a pipeline 11 is provided on the top right side of the water-sealed tank 1. The right side of water seal tank 1 is connected with explosion-proof fan 3 by pipeline 11, is connected to the bottom of water washing tank 5 by pipeline 11 on the right side of explosion-proof fan 3, forms gas pipeline 12, between explosion-proof fan 3 and water washing tank 5 A gas inlet 4 is provided on the pipeline 11 between them, a liquid inlet 6 is provided on the upper left side of the water washing tank 5, a second burst disc 8 is provided on the upper right side of the water washing tank 5, and a second bursting disc 8 is provided on the top pipe 11 of the water washing tank 5. There is a gas outlet 7, a porous sieve plate 10 is provided at the bottom of the washing tank 5, a li...

Embodiment 2

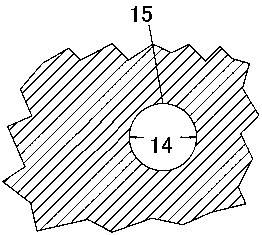

[0034] Embodiment 2: in combination with image 3 and 4 , the present invention is further described:

[0035] The vacuum tail gas to be treated contains 20% methanol and 80% air, which is divided into numerous bubbles with a diameter of 1cm by the sieve plate in the washing tank, and the methanol gas in the bubbles passes through the spherical surface to the water. The spherical surface of the bubble is a stable interface, and there is a very thin stagnation film 15 on both sides of the interface. Methanol passes through the inner gas film 15.1 and the outer liquid film 15.2 in the form of molecular diffusion, and enters the main body of the liquid phase from the gas phase.

[0036] At the phase interface, the gas and liquid phases reach equilibrium, and in the main body of the gas and liquid phases outside the two stagnant films of the gas film and the liquid film, due to the sufficient turbulence of the fluid, the material composition is uniform.

[0037] After the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com