A membrane transfer sewage treatment machine

A sewage treatment machine and sewage technology, applied in the direction of osmosis/dialysis water/sewage treatment, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low water filtration efficiency, wasting clean water, and turning clean water back into sewage, so as to reduce filtration Membrane material loss, saving production costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

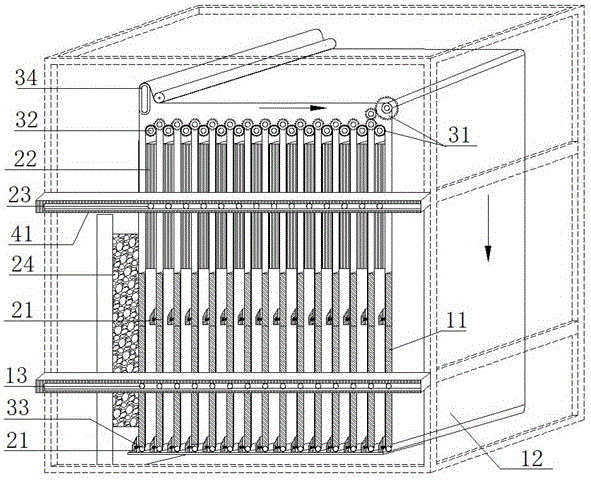

[0026] see figure 1 As shown, a membrane-transferred sewage treatment device of the present invention includes a sewage filtration system, a membrane cleaning system, and a membrane conveying system.

[0027] The sewage filtration system includes a plurality of water-absorbing plates 11 disposed in the sewage and arranged at intervals, filter membranes 12 covering both surfaces of the water-absorbing plates 11, and a first suction device connected to the water-absorbing plates 11; wherein , the filter membrane 12 preferably adopts a high-strength nano-scale water filtration membrane. According to the characteristics of the filter membrane 12, the contact surface of the filter membrane 12 and the water-absorbing plate 11 is a fiber surface, and the surface in contact with the sewage is a smooth surface; the water-absorbing plate Both sides of 11 are provided with arrays of water tanks, and filter membrane 12 is covered on the array of water tanks to form a negative pressure cav...

Embodiment 2

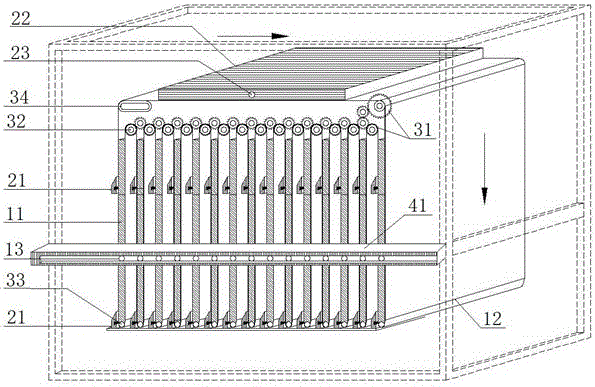

[0038] see figure 2 As shown, compared with Embodiment 1, the main difference is that: the membrane washing plate 22 can be provided with one piece, which is arranged outside the end area where the filter membrane 12 completes one cycle, and is smooth with the filter membrane 12 that is separated from the sewage. In addition, the filter membrane cleaning system can also be provided with an ultrasonic water washing device, which is installed on the transport path before the filter membrane 12 from sewage enters the membrane washing plate 22, and is used for loosening the filter membrane 12 microns. The obstinate impurities in the pores are conducive to the dredging of the micropores of the filter membrane 12 by the subsequent membrane washing plate 22 .

Embodiment 3

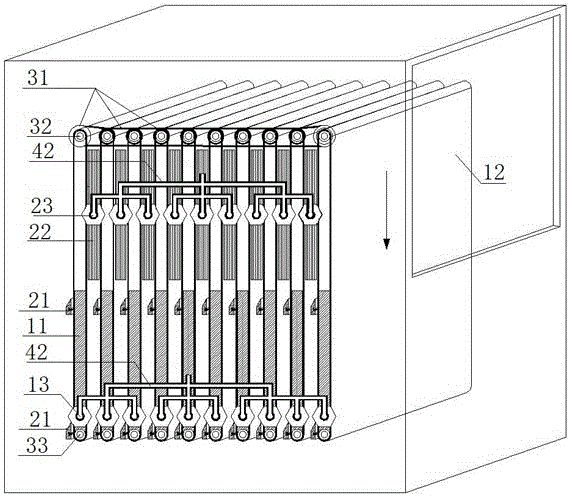

[0040] see image 3 As shown, compared with Embodiment 1, the main difference is that: the driving shaft 32 and the driven shaft 33 are distributed in two rows up and down, and the sewage filtration system is provided with a plurality of belt-shaped filter membranes 12 connected end to end. , the filter membranes 12 are respectively circularly transported around a set of corresponding driving shafts 32 and driven shafts 33 facing up and down. Correspondingly, the membrane washing plate 22 is provided with a plurality of pieces, which are respectively arranged between two adjacent filter membranes 12 which are circulated and transported, and are dislocated with the water absorbing plate 11 in two rows up and down, left and right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com