A kind of extraction washing method of low chloride ion high-purity cobalt sulfate

A washing method and chloride ion technology, applied in the metallurgical field, can solve the problems of high chloride ion, clogging of extraction tank by calcium and magnesium sulfate, etc., and achieve the effect of improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

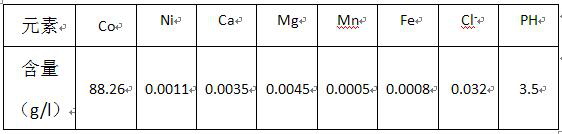

Embodiment 1

[0017] The raffinate obtained after leaching cobalt-containing raw materials by conventional methods and P204 extraction to remove impurities has a quality of Co38.26g / l, Ni 0.25g / l, Ca 0.015g / l, Mg 1.58g / l, Mn 0.0008g / l, Fe 0.0015g / l. The production steps are as follows:

[0018] 1) Add the above raffinate to P507 organic extraction to separate nickel and cobalt. The P507 organic extractant and sulfonated kerosene are mixed and prepared at a mass ratio of 1:4, and are subjected to countercurrent extraction in a 10-stage extraction box. The extraction process is saponified with liquid caustic soda, controlled The saponification rate is 55%, the obtained nickel sulfate solution is transferred to the nickel system, and the obtained loaded organic washing nickel is removed to remove magnesium;

[0019] 2) The first stage of washing: the load in the step 1) is organically entered into the first stage of the washing stage for countercurrent washing, and 1.0N hydrochloric acid is a...

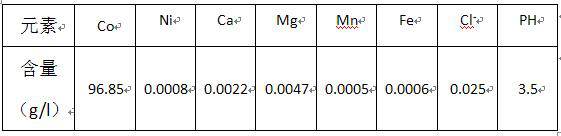

Embodiment 2

[0024] After leaching cobalt-containing raw materials by conventional methods, P204 extraction and removal of impurities, the obtained raffinate has a quality of Co4 2.18g / l, Ni 0.35g / l, Ca 0.022g / l, Mg 2.33g / l, Mn 0.0008g / l, Fe 0.0012g / l. The production steps are as follows:

[0025] 1) Add the above raffinate to P507 organic extraction to separate nickel and cobalt. The P507 organic extractant and sulfonated kerosene are mixed and prepared at a mass ratio of 1:5, and are subjected to countercurrent extraction in a 10-stage extraction box. The extraction process is saponified with liquid caustic soda, controlled The saponification rate is 60%, the obtained nickel sulfate solution is transferred to the nickel system, and the obtained load is organically washed to remove magnesium;

[0026] 2) The first stage of washing: the load in the step 1) is organically entered into the first stage of the washing stage for countercurrent washing, and 1.5N hydrochloric acid is added to wa...

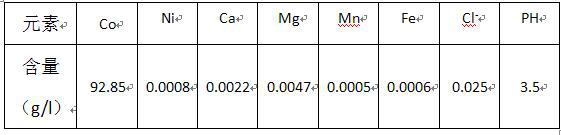

Embodiment 3

[0031] The raffinate obtained after leaching cobalt-containing raw materials by conventional methods and P204 extraction to remove impurities has a quality of Co40.18g / l, Ni 0.35g / l, Ca 0.022g / l, Mg 2.63g / l, Mn 0.0008g / l, Fe 0.0012g / l. The production steps are as follows:

[0032] 1) Add the above raffinate to P507 organic extraction to separate nickel and cobalt. The P507 organic extractant and sulfonated kerosene are mixed and prepared at a mass ratio of 1:5, and are subjected to countercurrent extraction in a 10-stage extraction box. The extraction process is saponified with liquid caustic soda, controlled The saponification rate is 60%, the obtained nickel sulfate solution is transferred to the nickel system, and the obtained load is organically washed to remove magnesium;

[0033] 2) The first stage of washing: the load in the step 1) is organically entered into the first stage of the washing stage for countercurrent washing, and 1.2N hydrochloric acid is added to wash a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com