Accelerating projectile support and method for non-empennage projectile body

A projectile and tail technology, which is applied in the direction of ammunition, ammunition testing, weapon accessories, etc., can solve the problems that the processing technology cannot meet the requirements, affect the attitude of the projectile hitting the target, interfere or be inseparable, and reduce the test cost. , Good target attitude, reducing the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

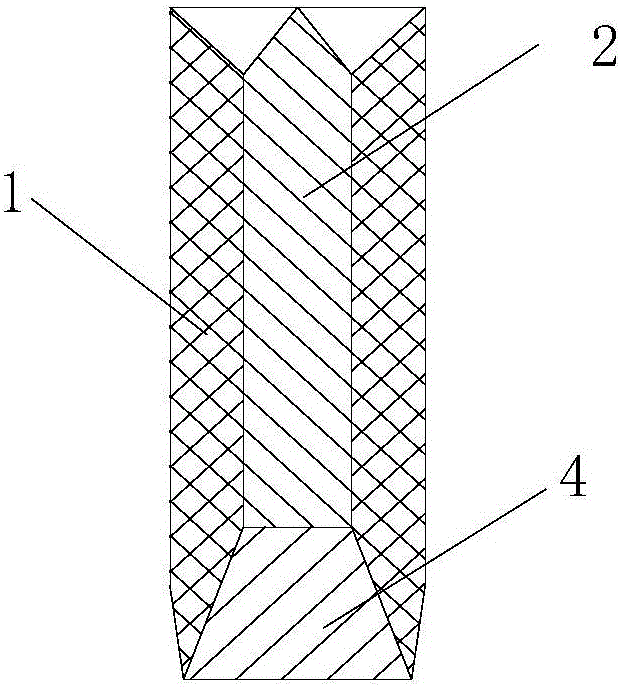

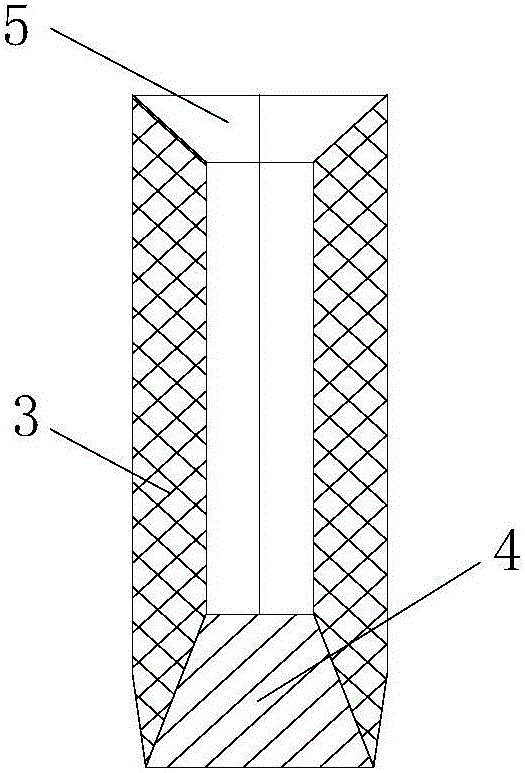

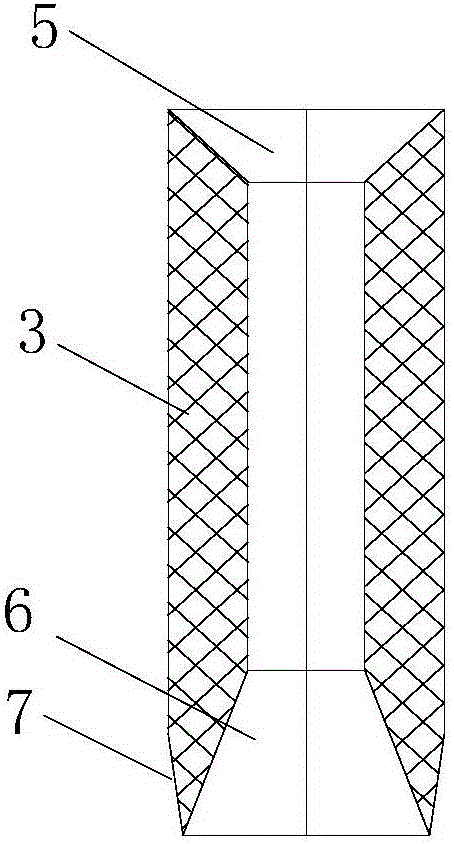

[0014] Embodiment 1, referring to the accompanying drawings, a tailless projectile acceleration bullet rest, comprising: a bullet rest main body 1 and a bottom pusher 4;

[0015] The main body 1 of the bullet holder is a circular tube formed by gluing the wall surfaces of 2 to 4 clips 3, and its length is 5 to 10 mm longer than that of the projectile; The central angle is 180 degrees at the same time, the central angle is 120 degrees when there are 3 clips 3, and the central angle is 90 degrees when there are 4 clips 3; Make it tightly fit in the launch barrel to play the role of air-holding; the inner diameter of the clip 3 is a negative tolerance, slightly smaller than the diameter of the projectile 2, so that the projectile 2 is tightly restrained inside the clip 3 without shaking to generate an angle of attack; The inner surface 5 of the head of the card valve 3 is an inverted conical surface; the inner surface 6 of the bottom is a right conical surface; the outer surface ...

Embodiment 2

[0020] Embodiment 2, a kind of tailless projectile acceleration method, it uses the non-finned projectile described in embodiment 1 to accelerate the bullet holder, and adopts 10mm~30mm launch barrel, 4 / 7 stone gunpowder or high-pressure gas, to large length The diameter ratio of the tailless projectile 2 accelerates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile yield strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com