Method for chromatography determination of organic functional additive content in azide polyether propellant

A technology of functional additives and determination methods, which is applied in the field of chromatographic analysis, can solve the problems of large error in experimental data, high risk of sample processing, and many steps in the measurement process, so as to improve reliability, make the detection method simple and easy, and ensure the development quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in two groups below in conjunction with the examples.

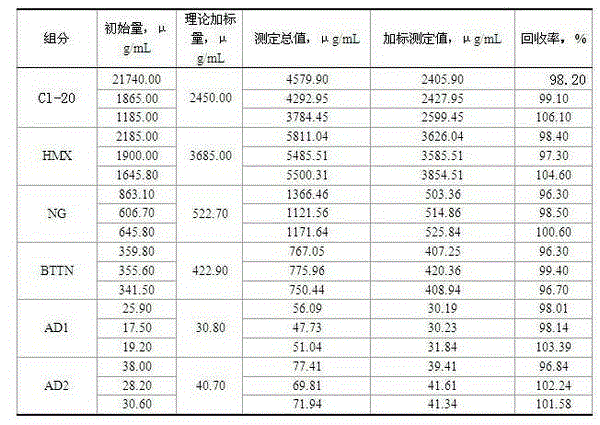

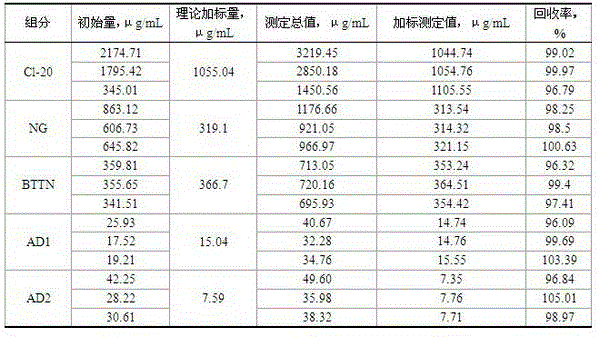

[0015] The first group, the determination of the content of functional additives in the azide polyether propellant with the oxidant hexanitrohexaazaisowurtzitane Cl-20 content of 60% by liquid chromatography.

[0016] Step 1, prepare test samples: obtain azide polyether propellant, cut into fine particles of 1mm×1mm×1mm, weigh 0.2–0.5g respectively, put them into a 50ml stoppered Erlenmeyer flask, add methanol, acetonitrile, chloroform, 20–30ml of one of the organic solvents such as acetone, ultrasonically extracted for 2-4 hours, soaked for at least 20 hours to form soaked extracts, and quantified by external standard method.

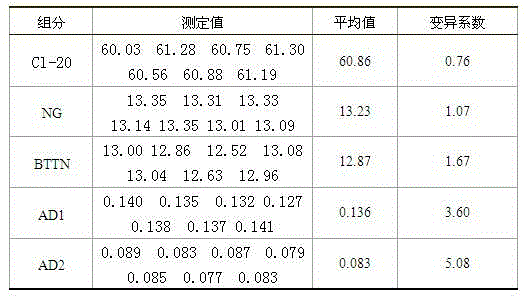

[0017] Step 2, determine the detection conditions: use high performance liquid chromatography HPLC to quantitatively measure the soaking extract, and use the organic functional additive in the azide polyether propellant as the detection object...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com