Continuous emission monitoring system for volatile organic compound pollutants in industrial flue gas

A volatile organic and industrial flue gas technology, used in measurement devices, air quality improvement, instruments, etc., can solve the problems of low replacement and maintenance costs, and achieve the goal of reducing replacement and maintenance costs, maintaining system safety, and avoiding condensation loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

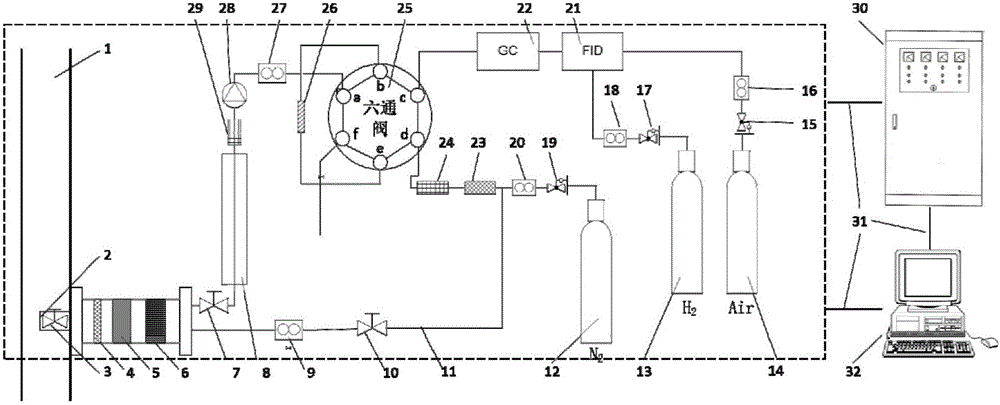

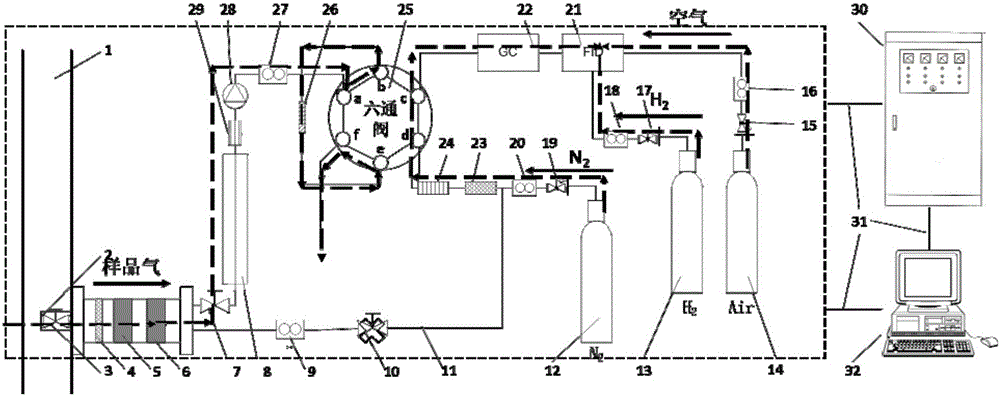

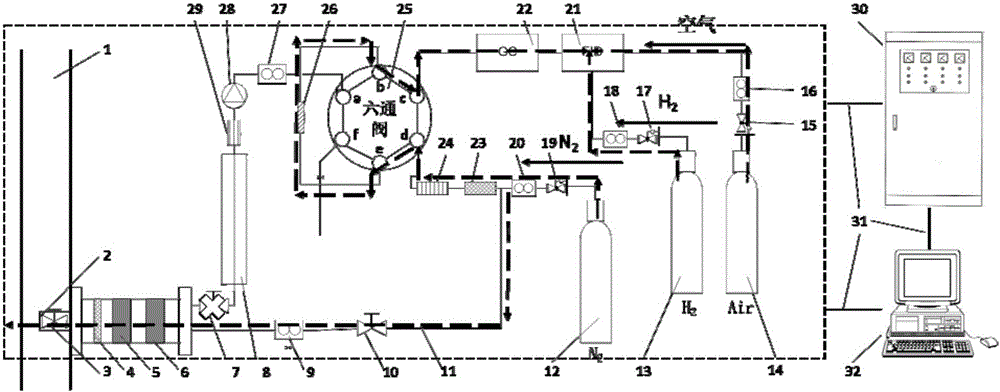

[0015] The overall structure of the CEMS for industrial flue gas VOCs of the present invention is as follows figure 1 As shown, the system includes five parts: sampling subsystem, blowback subsystem, gas supply subsystem, gas detection subsystem and control subsystem. The sampling subsystem includes a sampling probe 2 composed of a first solenoid valve 3 and a filter 4-6, a second solenoid valve 7, a heat tracing pipe 8, an oxygen removal pipe 29, an air pump 28, a first flow controller 27, six Through the valve 25 and the quantitative pipe 26, the filter includes a drying layer 4, a coarse filter screen 5 and a fine filter screen 6 arranged in sequence; wherein, the outlet of the sampling probe 2 is connected to the inlet of the second solenoid valve 7, and the inlet of the heating pipe 8 Connect to the outlet of the second solenoid valve 7, the outle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com