Preparation method for perovskite solar cell with tetramino zinc phthalocyanine organic hole transmission layer

A technology of tetraaminozinc phthalocyanine and solar cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve pollution, and the production efficiency of perovskite solar cells is not high, which limits the production and application of perovskite solar cells and other issues to achieve the effects of reducing environmental pollution, improving photoelectric conversion efficiency, and reducing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention are described in detail as follows:

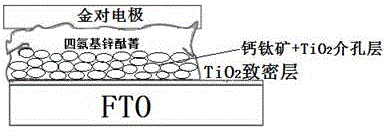

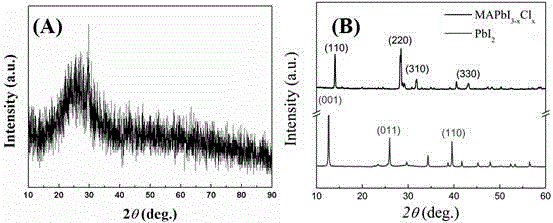

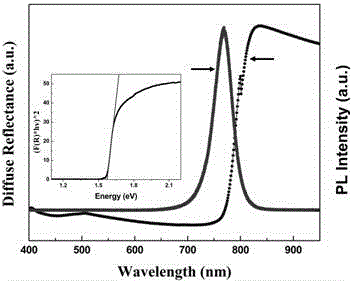

[0022] In this example, see Figure 1 to Figure 5 , a method for preparing a tetraaminozinc phthalocyanine organic hole transport layer perovskite solar cell, comprising the steps of:

[0023] 1) Preparation of tetraaminozinc phthalocyanine:

[0024]a. Preparation of tetranitrozinc phthalocyanine by microwave method: measure reactant raw material 4.03g zinc acetate, 21.11g4 -Nitrophthalic acid and 15g urea, then reactant raw material is mixed with the catalyzer tetrahydrate ammonium molybdate tetrahydrate of 0.2g to form reaction system material, after grinding evenly, then reaction system material is joined in the beaker of 500ml, then Put the beaker together with the materials of the reaction system in an oil bath at 140°C and stir for half an hour, then take the beaker out of the oil bath, and then put the beaker into a microwave oven. By adjusting the power of the microwave oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com