Spraying efficient electrostatic precipitator

An electrostatic precipitator and spray technology, which is applied in the field of high-efficiency spray electrostatic precipitators, can solve problems such as insufficient exhaust gas treatment, and achieve the effects of low raw material cost, stable properties, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

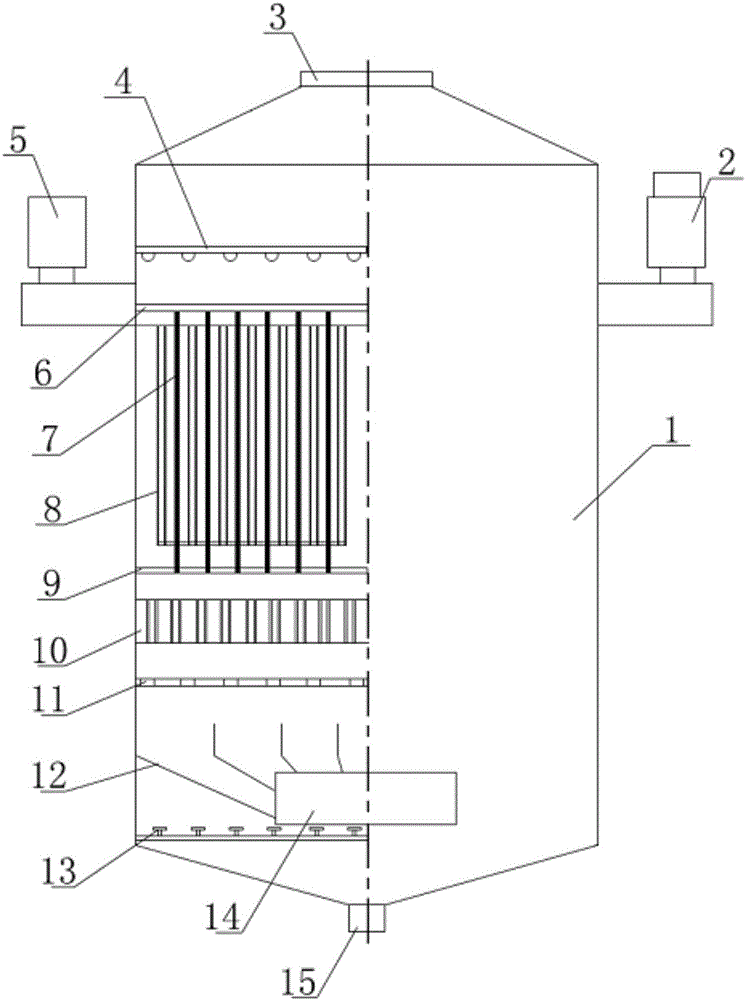

[0019] Refer to attached figure 1 According to the present invention, it includes a housing 1 with a smoke inlet 14 at the bottom; a smoke outlet 3 and a sewage outlet 15 are respectively provided at the upper and lower ends of the housing 1; Power supply 2 and insulating box 5; the middle part of the housing 1 is provided with an anode tube 7 and a cathode wire 8 fixedly connected to the housing 1 through an upper bracket 6 and a lower bracket 9 respectively; the anode tube 7 and cathode wire 8 They are respectively connected to the high-voltage power supply 2 through wires; the upper part of the upper bracket 6 is provided with a spray pipe 4; The connected spray pipe 13; the speed brake 11 is arranged above the splitter tank 12, and the adsorbent layer 10 is arranged between the speed brake 11 and the lower bracket 9, and the adsorbent layer 10 includes a container for placing the adsorbent fixedly.

[0020] Working principle: The flue gas enters from the smoke inlet and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com