Pipeline laser washing device based on curved surface holophote

A curved surface mirror and laser cleaning technology, which is applied in the field of laser cleaning, can solve the problems of unable to clean the surface of the pipeline, slow cleaning speed, easy to damage the pipeline, etc., and achieve the effect of convenient automatic operation, high cleaning efficiency and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

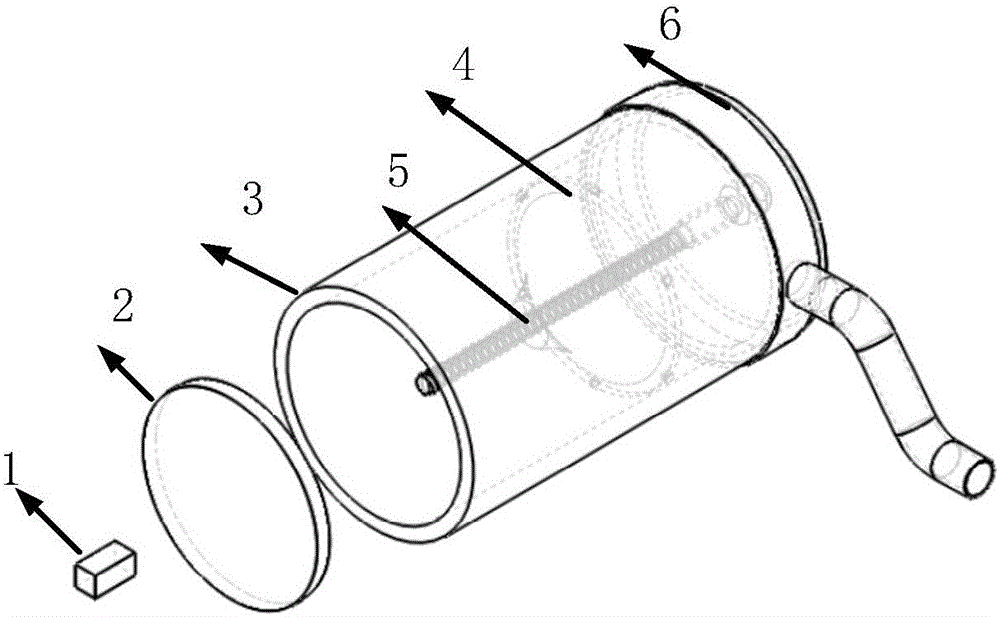

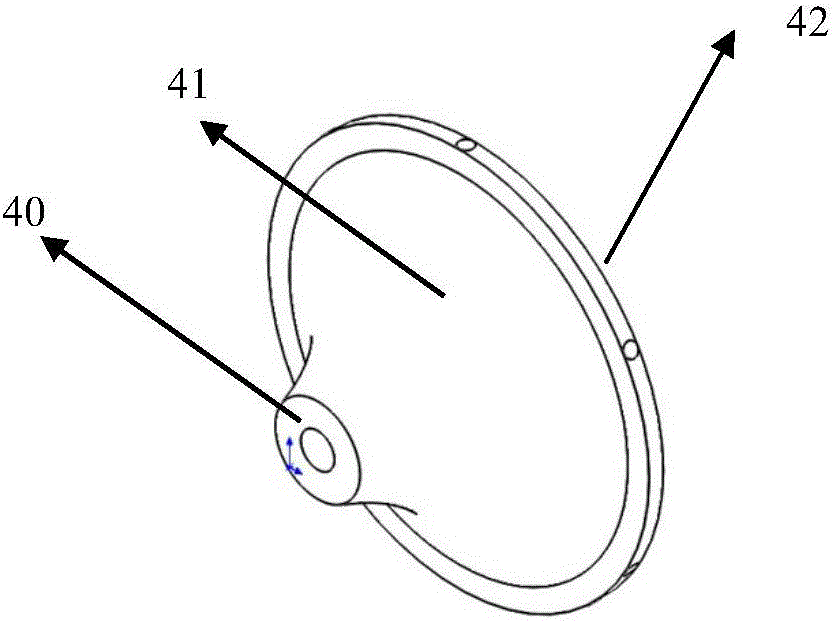

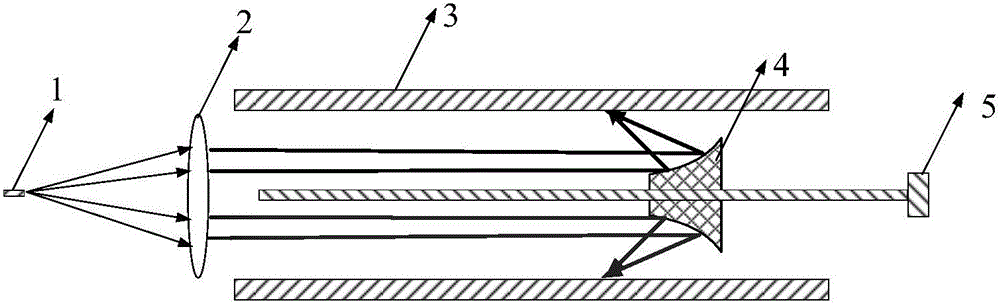

[0031] Such as figure 1As shown, the center of the laser 1, the lens system 2, and the curved total reflection mirror 4 are on the same straight line, the first direction is from the center of the curved mirror 4 to the center of the laser 1, and the second direction is the opposite direction. The curved surface reflector 4 is connected with the screw mandrel of the motor 5, so that when the screw mandrel rotates clockwise, the curved surface total reflection mirror 4 moves along the first direction, and when the screw mandrel rotates counterclockwise, the curved surface total reflection mirror 4 moves along the second direction. sports. The laser 1 is at a certain distance from the lens system 2, so that the laser light with a certain divergence angle emitted by the laser 1 can be collimated by the lens system 2. The lens system 2 is composed of one lens or multiple lenses, which are determined according to the required energy density and pass through the lens system. 2. The...

Embodiment 2

[0038] The laser 1, the lens system 2, and the center of the curved total reflection mirror 4 are on the same straight line, the first direction is from the center of the curved total reflection mirror 4 to the center of the laser 1, and the opposite direction is the second direction. The curved total reflection mirror 4 is connected with the motor 5 so that when the motor drives the screw mandrel to rotate clockwise, the curved surface total reflection mirror 4 moves along the first direction, and when the motor drives the screw mandrel to rotate counterclockwise, the curved surface total reflection mirror 4 moves along the first direction. Movement in two directions. The laser 1 is located at a certain distance from the lens system 2, so that the laser light with a certain divergence angle emitted by the laser 1 can be collimated by the lens system 2. The lens system 2 is composed of one lens or multiple lenses, which are determined according to the required energy density an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com