Non-chiller ductile iron non-riser casting technology

A casting process and iron ball technology, which is applied in the field of casting without chilled iron ductile iron without risers, can solve the problems of shrinkage cavities, shrinkage porosity defects, waste of production materials, and high production costs, and achieve low shrinkage porosity defect rate and molding. The effect of simple structure and simple casting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The no-chill ductile iron no-riser casting technique in the present embodiment, it comprises the following steps:

[0019] 1) Configure molding sand;

[0020] 2), making templates and core box tooling;

[0021] 3) Configure nodular iron raw materials, and carry out molten iron smelting and nodularization and inoculation of molten iron after it is released from the furnace;

[0022] 4), use the configured molding sand to make casting cavity and sand core;

[0023] 5) Set up a pouring system consisting of slag avoidance bag, inner sprue, sprue, and runner, and set core and box together;

[0024] 6), pouring molten iron, and after the casting is formed and cooled, the casting is sanded and cleaned;

[0025] Wherein: the casting cavity is not provided with a riser; the ingate of the ingate uses a flat gate; the interior of the casting cavity is not provided with a cold iron. The ratio of the height to the width of the flat gate is 1:5.25.

[0026] The molding sand desc...

Embodiment 2

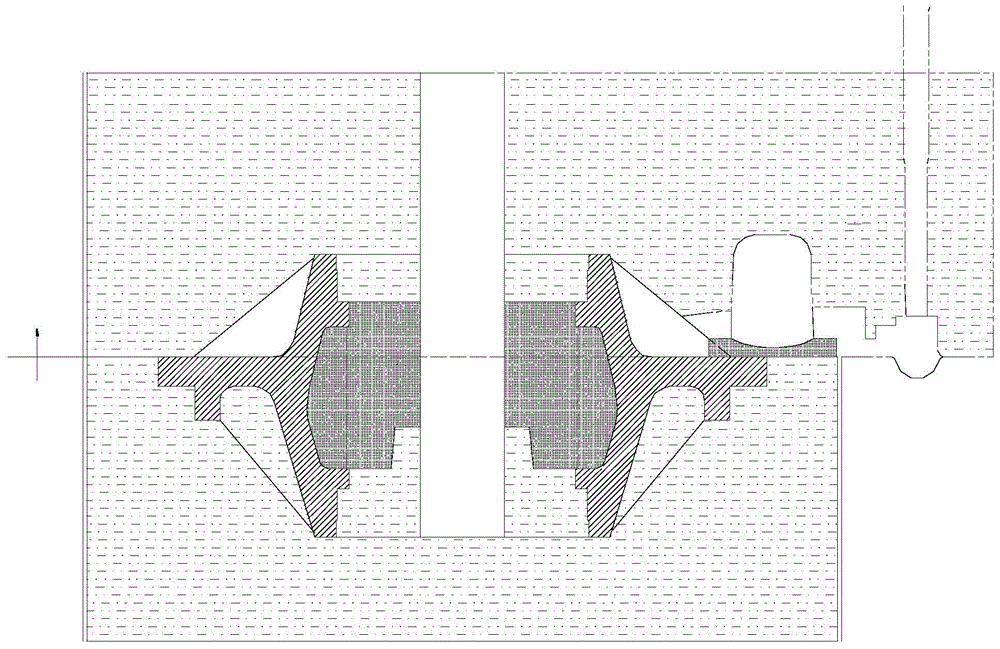

[0028] like figure 1 As shown, in the present embodiment, utilize no-chill iron nodular iron no riser casting technology to cast super large automobile hub, it comprises the following steps:

[0029] 1) Configure molding sand;

[0030] 2) According to the process design drawing, make the upper and lower mold templates, core boxes and positioning pins of the casting;

[0031] 3) Configure nodular iron raw materials, and carry out molten iron smelting and nodularization and inoculation of molten iron after it is released from the furnace;

[0032] 4), use the configured molding sand to make casting cavity and sand core:

[0033] (1), use the core box to make sand core;

[0034] (2) Make the lower mold, install the lower sand box on the lower mold template, fill the lower sand box with molding sand and shake it tightly, after the sand filling is completed, the mold will be released when the strength of the molding sand hardens to 5MPa;

[0035] (3) Make the upper mold, instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com