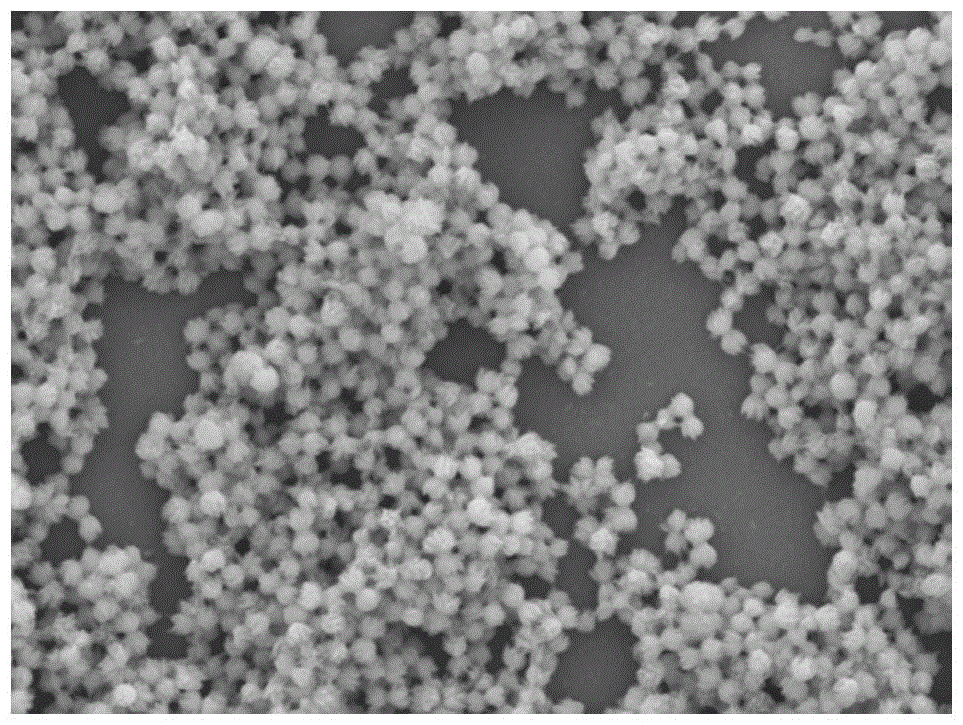

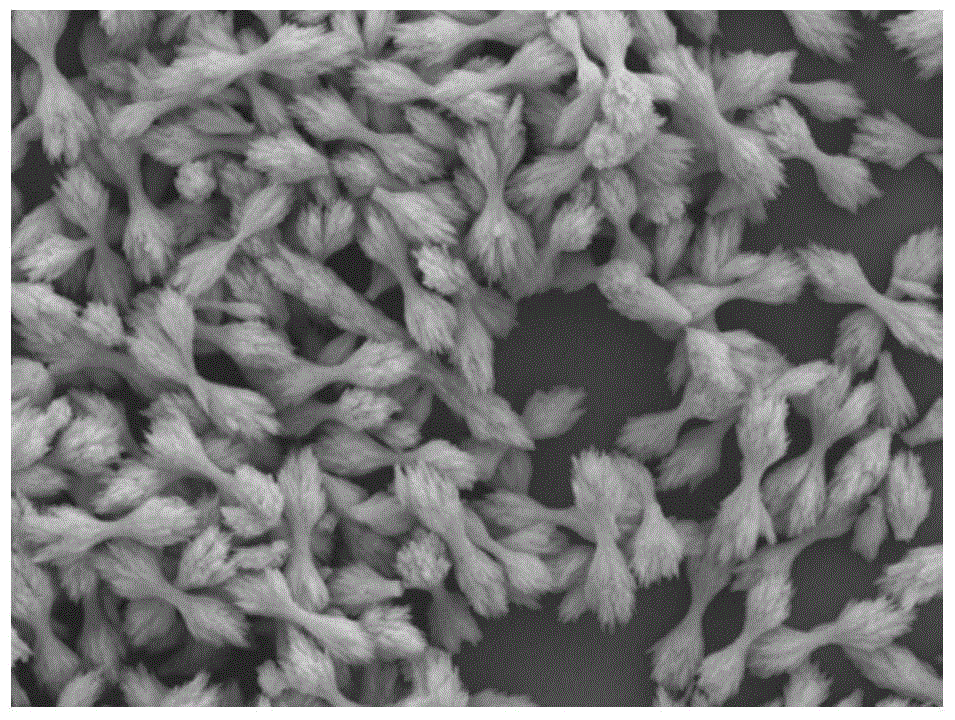

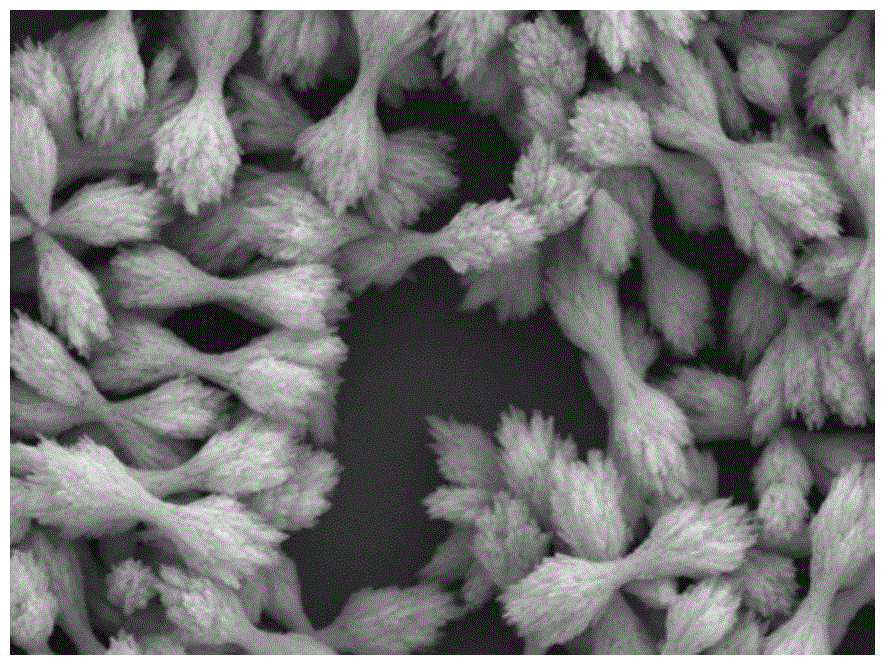

Preparation method for monodisperse dumbbell-shaped barium carbonate particles

A dumbbell-shaped, barium carbonate technology, applied in directions such as barium carbonate, calcium carbonate/strontium/barium, etc., can solve the problems of unfavorable industrialized production, harsh reaction conditions, high material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve barium hydroxide octahydrate into a mixed solvent of ethylene glycol and water (ethylene glycol: water: 8:2) to make a 0.02mol / L barium hydroxide solution, and measure it at twice the concentration of barium hydroxide Add diethyl carbonate to the solution, react at room temperature (about 20°C) for 3 hours, the pH of the solution drops to 7.6 to end the reaction, filter the precipitate, wash with ethanol to remove the solvent, and place it at room temperature to remove ethanol. Monodisperse dumbbell-shaped barium carbonate particles were obtained.

Embodiment 2

[0023] Dissolve barium hydroxide octahydrate into a mixed solvent of propylene glycol and water (ethylene glycol: water ratio of 9:1) to make a 0.1mol / L barium hydroxide solution, and use a metering ratio of 2 times the concentration of barium hydroxide in Add diethyl carbonate to the solution, react at room temperature (about 20°C) for 3 hours, the pH of the solution drops to 6.5 to end the reaction, filter the precipitate and wash with ethanol to remove the solvent, place it at room temperature to remove ethanol, and obtain mono Disperse dumbbell-shaped barium carbonate particles.

Embodiment 3

[0025] Dissolve barium hydroxide octahydrate into a mixed solvent of diethylene glycol and water (ethylene glycol: water: 5:1) to make a 0.02mol / L barium hydroxide solution, and measure it at twice the concentration of barium hydroxide Add dimethyl carbonate to the solution, react at room temperature (about 20°C) for 3 hours, the pH of the solution drops to 7.1 to complete the reaction, filter the precipitate, wash with ethanol to remove the solvent, and place it at room temperature to remove ethanol. Monodisperse dumbbell-shaped barium carbonate particles were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com