Early-strength polycarboxylate superplasticizer and preparation method and application thereof

A polycarboxylic acid and early-strength technology, which is used in the field of early-strength polycarboxylate water reducer and its preparation, can solve the problems of long concrete setting time, insignificant early-strength effect, and poor dispersibility, and achieve early-strength effect. Good, ensure the strength, the effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

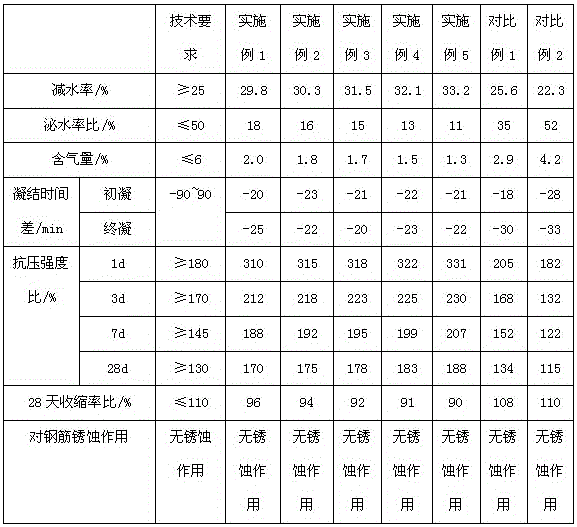

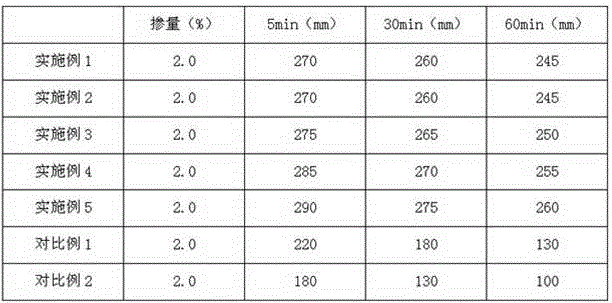

Examples

Embodiment 1

[0020] In the embodiment of the present invention, an early-strength polycarboxylate water reducer is composed of the following raw materials in parts by weight: 55 parts of polyacrylic acid, 33 parts of ethylenediaminetetraacetic acid, 5 parts of rectorite, and 15 parts of woody fragrance , 8 parts of polyethyleneimine.

[0021] Add deionized water 10 times its mass to polyacrylic acid, stir for 5 minutes, then add polyethyleneimine, then raise the temperature to 55°C, and treat at this temperature for 300 minutes to prepare a polyacrylic acid mixture for use. Grind and pass through an 80-mesh sieve, add 8 times the mass of absolute ethanol, heat to 70°C and stir for 20 minutes, then perform ultrasonic treatment for 30 minutes with an ultrasonic power of 800W to obtain ultrasonic treatment solution A. Crush the rectorite and pass through a 200-mesh sieve, then add ethylenediaminetetraacetic acid and mix with deionized water 4 times the mass of the rectorite, and then heat up ...

Embodiment 2

[0023] In the embodiment of the present invention, an early-strength polycarboxylate water reducer is composed of the following raw materials in parts by weight: 63 parts of polyacrylic acid, 42 parts of ethylenediaminetetraacetic acid, 12 parts of rectorite, and 23 parts of woody , 14 parts of polyethyleneimine.

[0024] Add 12 times the mass of deionized water to polyacrylic acid, stir for 10 minutes, then add polyethyleneimine, then raise the temperature to 60°C, and treat at this temperature for 40 minutes to prepare a polyacrylic acid mixture for use. Grind and pass through a 120-mesh sieve, add 10 times the mass of absolute ethanol, heat to 75°C and stir for 30 minutes, then perform ultrasonic treatment for 40 minutes with an ultrasonic power of 1000W to obtain ultrasonic treatment solution A. Crush the rectorite and pass through a 200-mesh sieve, then add ethylenediaminetetraacetic acid and mix with deionized water 5 times the mass of the rectorite, and then heat up to ...

Embodiment 3

[0026] In the embodiment of the present invention, an early-strength polycarboxylate water reducer is composed of the following raw materials in parts by weight: 57 parts of polyacrylic acid, 35 parts of ethylenediaminetetraacetic acid, 7 parts of rectorite, and 17 parts of woody fragrance , 10 parts of polyethyleneimine.

[0027] Add 11 times the mass of deionized water to polyacrylic acid, stir for 8 minutes, then add polyethyleneimine, then raise the temperature to 60°C, and treat at this temperature for 40 minutes to prepare a polyacrylic acid mixture for use. Grind and pass through a 120-mesh sieve, add 9 times the mass of absolute ethanol, heat to 75°C and stir for 30 minutes, then perform ultrasonic treatment for 40 minutes with an ultrasonic power of 1000W to obtain ultrasonic treatment solution A. Crush the rectorite and pass through a 200-mesh sieve, then add ethylenediaminetetraacetic acid and mix with deionized water 4.5 times the mass of the rectorite, and then he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com