Method of recycling isooctanol from waste solvent in production process of isooctyl thioglycolate

A technology of isooctyl thioglycolate and isooctyl acetate, applied in the field of chemical separation, can solve the problems of high boiling point, inability to realize distillation operation, low content of thioglycolic acid, etc., and achieve high product purity, reduced energy consumption, and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

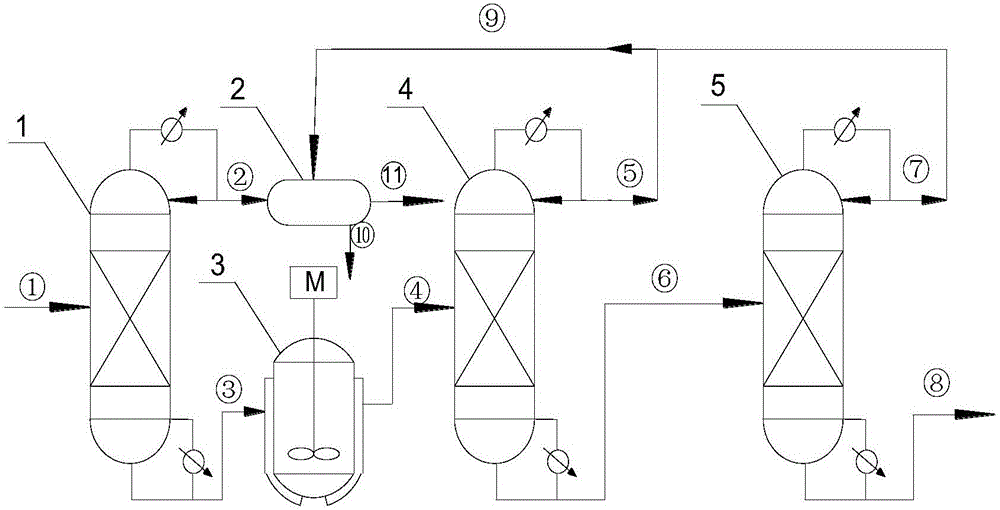

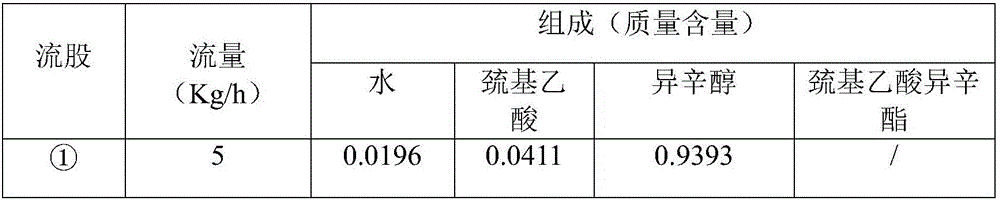

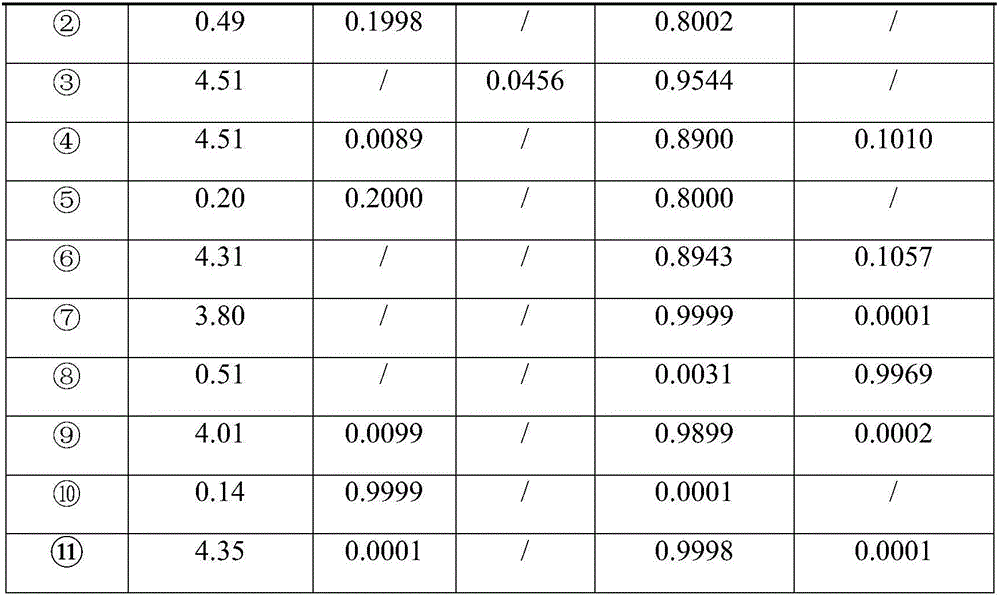

[0028] Embodiment 1: the method for reclaiming isooctyl alcohol from mercaptoacetic acid-water-isooctanol system in combination with rectification process, with reference to figure 1 Process flow shown. The waste liquid produced in the production process of isooctyl thioglycolate is used as raw material ①, wherein the mass contents of thioglycolic acid, water, and isooctyl alcohol are 4.11%, 1.96%, and 93.93% respectively (the flow rate is 5Kg / h), and raw material ① enters Rectification tower Ⅰ, the temperature of the control tower is 186.1-189.3 ℃, the temperature of the tower top is 95.2-97.5 ℃, the reflux ratio is 3, after rectification separation, the azeotrope of isooctyl alcohol and water is obtained from the top of the rectification tower ② (Flow rate 0.49Kg / h, its composition is X 异辛醇 =0.8002,X 水 =0.1998), and it is passed in the liquid separator 2; The mixed solution ③ (flow rate 4.51Kg / h, its composition is X 异辛醇 =0.9544,X 巯基乙酸 =0.0456) into the reactor 3, with p...

Embodiment 2

[0042] The operation steps adopted are the same as in Example 1, the difference is that the mass content of thioglycolic acid in the waste liquid produced in the production process of the used raw material isooctyl thioglycolate is 5%, the mass content of water is 2.2%, and the mass content of isooctanol was 92.8%.

Embodiment 3

[0044] The operation steps adopted are the same as in Example 1, the difference is that the mass content of thioglycolic acid in the waste liquid produced in the production process of the used raw material isooctyl thioglycolate is 6%, the mass content of water is 2.8%, and the mass content of isooctyl alcohol is 6%. was 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com