Extraction method of pectin and polyphenol in orange peel

An extraction method and a citrus peel technology are applied in the field of simultaneous extraction and preparation of pectin and polyphenols from citrus peel residue based on subcritical water technology, which can solve problems such as large waste water, environmental pollution, complicated processes, etc., and achieve pollution reduction and extraction. The effect of high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

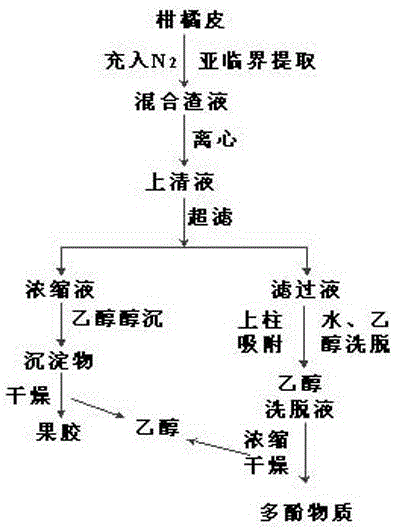

[0040] A method for extracting pectin and polyphenols in citrus peel, the technological process is as follows figure 1 shown, including the following steps:

[0041] (1) Pulverization: Take 500g of fresh orange peel with a moisture content of 82% on a wet basis, and pulverize it into particles with a particle size of 0.5mm to 2mm.

[0042] (2) Subcritical water extraction: put the orange peel particles obtained in step (1) in a stainless steel extraction kettle, add 1 L of distilled water, fill with nitrogen, and let the gas out for 5 minutes, and use subcritical water as the extraction solvent to extract the orange peel particles. Dynamic subcritical extraction, the extraction time is 10min, the subcritical pressure of the stainless steel extraction kettle is 8MPa, the temperature is 130°C, the stirring speed is 100rpm, and the extraction is cooled.

[0043] (3) Centrifugation: Centrifuge the slag liquid after cooling in step (2) at 4000 × g for 10 min at room temperature, a...

Embodiment 2

[0050] A method for extracting pectin and polyphenols in citrus peel, the technological process is as follows figure 1 shown, including the following steps:

[0051] (1) Pulverization: Take 100 g of navel orange peel dried at 105°C and pulverize it into particles with a particle size of 0.03 mm to 0.3 mm to obtain orange peel powder.

[0052] (2) Subcritical water extraction: put the orange peel powder obtained in step (1) in a stainless steel extraction kettle, add 1.2 L of distilled water, fill with nitrogen, and let it out for 5 minutes, and use subcritical water as the extraction solvent to extract the orange peel powder. Dynamic subcritical extraction was performed, the extraction time was 8 min, the subcritical pressure of the stainless steel extraction kettle was 9 MPa, the temperature was 150° C., the stirring speed was 150 rpm, and the extraction was followed by cooling.

[0053] (3) Centrifugation: Centrifuge the slag liquid after cooling in step (2) at 5000 × g for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com