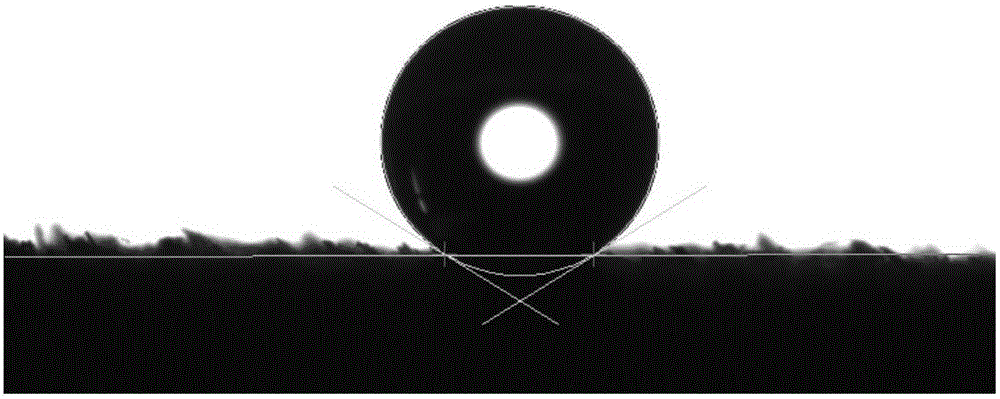

Preparation method of super-hydrophobic oleophobic transparent nanocellulose paper

A nano-cellulose, super-hydrophobic and oleophobic technology, applied in the direction of synthetic cellulose fiber, non-fibrous pulp addition, fiber raw material treatment, etc., can solve the problems of opacity and poor hydrophobicity of nano-paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

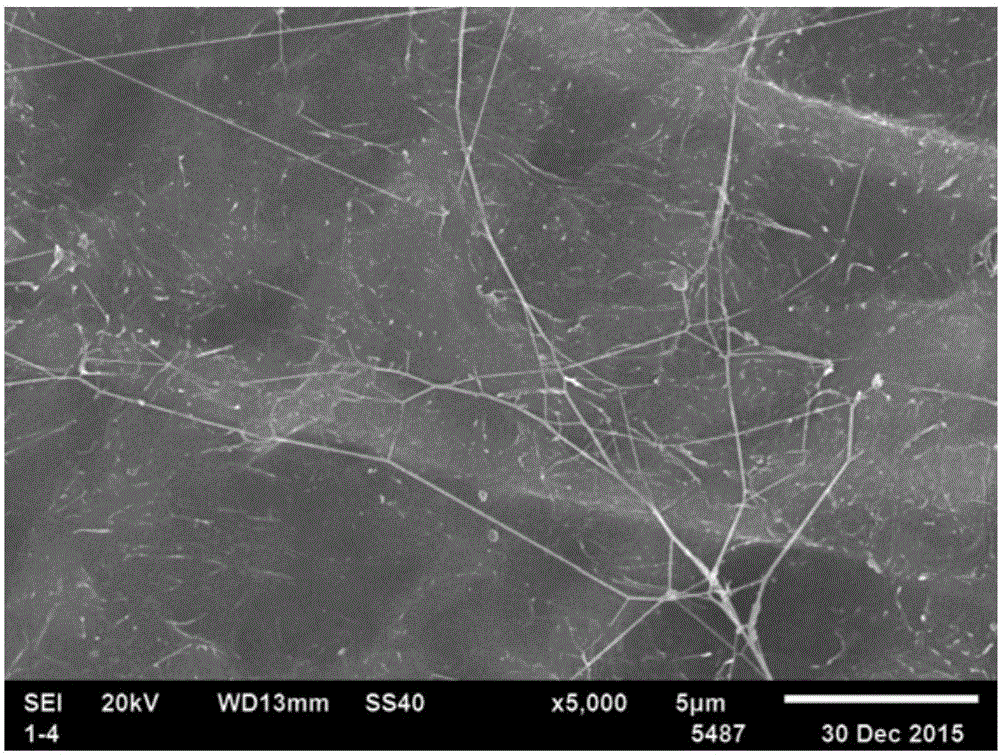

[0037] Specific embodiment one: the preparation method of superhydrophobic and oleophobic transparent nanocellulose paper of this embodiment is carried out according to the following steps:

[0038] 1. Preparation of nanocellulose aqueous solution:

[0039] Add purified cellulose into a 250ml beaker, add deionized water to a mass concentration of 0.1%-0.3%, add 2g of cellulase, pretreat at 50°C for 2h, then treat at 90°C for 2h, then vacuum filter After washing with water, reconstitute the water solution with a mass concentration of 0.1%-0.3%, and then undergo a 600bar high-pressure homogenization mechanical treatment for 30 minutes to obtain the nanocellulose water solution;

[0040] Or put purified cellulose into a 250ml beaker, add deionized water to a mass concentration of 0.1%-0.3%, add 0.1g sodium bromide, 0.016g TEMPO reagent in turn, and add 5ml of 12% TEMPO reagent under magnetic stirring Sodium hypochlorite solution, add the sodium hydroxide that concentration is 0....

specific Embodiment approach 2

[0045] Embodiment 2: This embodiment differs from Embodiment 1 in that the organoalkoxysilane described in step 2 is ethyl orthosilicate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, 6% organoalkoxysilane, 20% deionized water and 74% absolute ethanol are mixed by mass percentage . Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile stress | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com