Fast recovery diode material slice structure containing cathode auxiliary part and manufacturing method thereof

A technology for recovering diodes and auxiliary structures, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems of short recombination time, long transition zone, and high cost of epitaxial wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

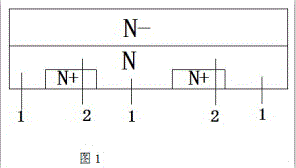

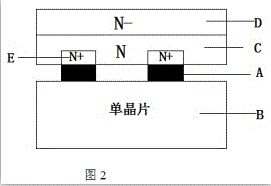

[0012] Such as figure 2 , Diffusion of phosphorus (1260°C, 2h) on the back of a low-doped N-monocrystalline silicon wafer (thickness 260um) to form an N-type region (C), with a junction depth of 20um, and then use the screen printing process, the screen uses 800 mesh For processing, the scraper uses a rubber knife, the scraper pressure is 3kg, the scraper speed is 70mm / s, and a layer of phosphorus latex source (A) is coated on the surface of the N area (C), with a viscosity of about 150CP, baked on a hot plate at 200°C for 1min, After baking, the thickness of the latex source is 20um, and the width is 100um. A single wafer (B) is adhered to the coated surface of the silicon wafer (A), and the two adhered silicon wafers are diffused at a high temperature of 1200°C to form dot-shaped N+ Area (E), N+ junction depth at 5um, surface concentration at 1E19 / cm 2 Above, the N+ area (E) and the N area (C) form the auxiliary part of the cathode. After the furnace is released, the front...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com